Spheroidal Graphite Iron, also known as ductile iron or nodular iron, is a type of cast iron that offers enhanced durability and resilience compared to other cast iron materials. It is widely used in various industrial applications where strength, toughness, and resistance to wear are crucial.

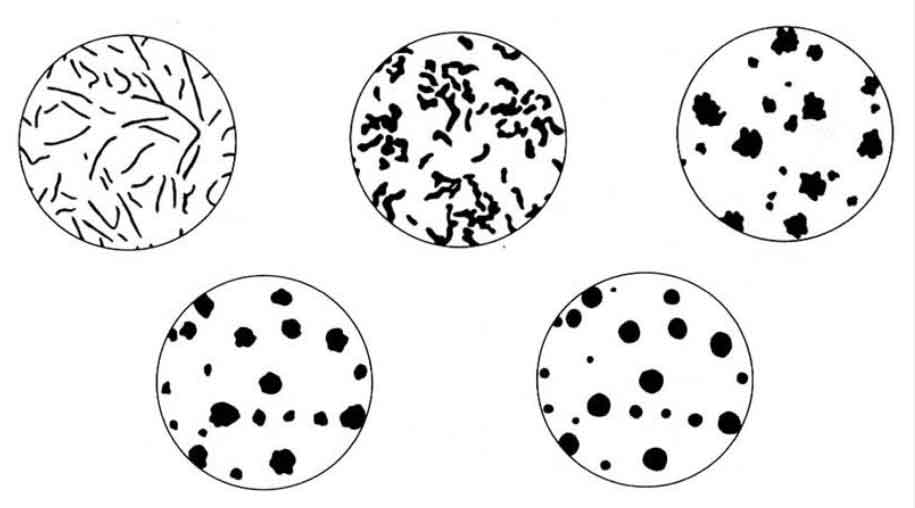

The unique microstructure of SGI is responsible for its improved mechanical properties. While traditional gray iron has graphite flakes in its structure, SGI has graphite nodules or spheroids, which provide greater strength and ductility. These nodules act as stress concentrators and prevent the propagation of cracks, making SGI highly resistant to fatigue and impact loads.

Here are some key factors that contribute to the enhanced durability and resilience of Spheroidal Graphite Iron:

- Nodular Graphite Structure: The graphite nodules in SGI act as “crack-arresters.” When a crack encounters a nodular graphite, it is deflected, absorbed, or terminated, preventing further crack propagation. This behavior significantly improves the fatigue strength and impact resistance of the material.

- Matrix Structure: The matrix of SGI consists of a ferritic or pearlitic matrix, which provides high tensile strength and stiffness. The matrix supports the graphite nodules and contributes to the overall mechanical properties of the material.

- High Tensile Strength: SGI exhibits a higher tensile strength compared to gray iron. This property allows it to withstand higher loads and stresses without failure. It is particularly advantageous in applications where the material is subjected to dynamic or cyclic loading.

- Improved Ductility: The graphite nodules in SGI act as “pillars” that hinder the movement of dislocations within the material, leading to improved ductility. This ductility allows SGI to undergo substantial deformation before failure, making it more resistant to crack initiation and propagation.

- Wear Resistance: SGI has excellent wear resistance due to the presence of graphite nodules, which act as lubricating agents, reducing friction and wear between surfaces. This makes SGI suitable for applications involving sliding or abrasive wear, such as gears, bearings, and wear-resistant components.

- Machinability: SGI offers good machinability compared to other materials with similar strength properties. It can be easily machined into complex shapes, allowing for the production of intricate components with precise dimensions.

Due to its exceptional properties, Spheroidal Graphite Iron finds application in a wide range of industries, including automotive, machinery, oil and gas, construction, and mining. It is commonly used in engine components, crankshafts, cylinder blocks, gears, valves, pipe fittings, and many other critical parts that require high strength, durability, and resistance to wear.

It’s worth noting that the specific properties and performance of SGI can be influenced by factors such as the nodularity level, matrix structure, and heat treatment. These factors can be tailored to suit the specific requirements of different applications, further enhancing the material’s durability and resilience.