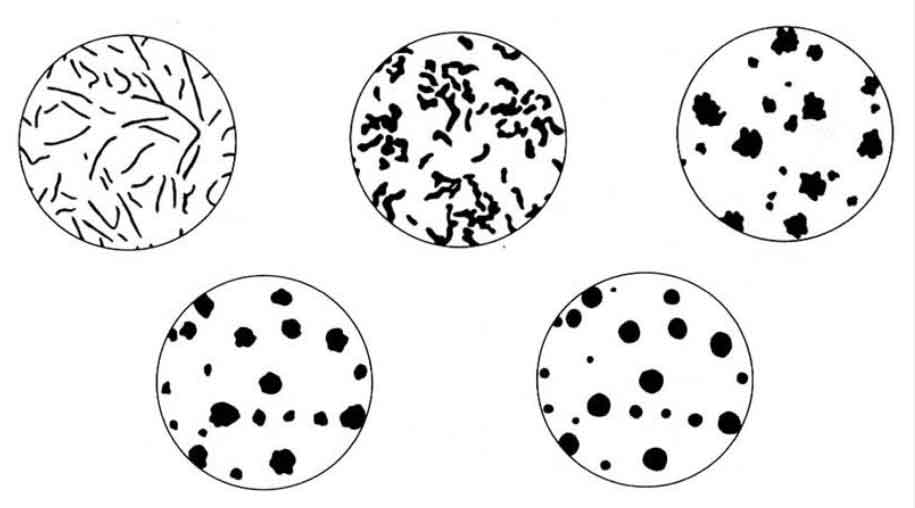

Spheroidal Graphite Iron, also known as Ductile Iron or Nodular Iron, is indeed a material that is highly favored for high-stress environments due to its unique combination of strength, ductility, and toughness. It is a type of cast iron that has graphite nodules embedded within its matrix, giving it superior mechanical properties compared to traditional gray iron.

Here are some key reasons why Spheroidal Graphite Iron is the material of choice for high-stress environments:

- Strength: Spheroidal Graphite Iron has excellent strength properties, making it capable of withstanding high loads and stresses. It has a higher tensile strength than gray iron and is comparable to some steels. This enhanced strength allows Spheroidal Graphite Iron components to handle heavy loads without deformation or failure.

- Ductility: Unlike conventional gray iron, Spheroidal Graphite Iron exhibits significant ductility. The graphite nodules present in the microstructure act as stress concentrators, preventing the propagation of cracks. This ductility allows spheroidal Graphite Iron components to absorb energy and deform under stress, reducing the likelihood of sudden failure or catastrophic fractures.

- Toughness: Spheroidal Graphite Iron demonstrates exceptional toughness, which refers to its ability to resist fracture under impact or dynamic loading conditions. The graphite nodules act as “crack arrestors” by deflecting cracks and preventing their propagation, thereby increasing the overall toughness of the material.

- Fatigue Resistance: Spheroidal Graphite Iron has superior fatigue resistance compared to many other cast metals. Its ability to endure cyclic loading without failure makes it well-suited for applications subjected to repeated stresses, such as automotive components, crankshafts, gears, and heavy machinery parts.

- Machinability: Spheroidal Graphite Iron is relatively easy to machine, allowing for the production of complex components with intricate shapes. This makes it a preferred choice for applications where precise machining is required.

- Cost-effectiveness: Spheroidal Graphite Iron offers an excellent balance between performance and cost. While it may be more expensive than traditional gray iron, it is often a more cost-effective option compared to alternative materials like steel or aluminum alloys in high-stress environments.

Due to these favorable properties, Spheroidal Graphite Iron finds widespread use in various industries and applications. Some common examples include automotive components (such as engine blocks, crankshafts, and suspension components), heavy machinery parts, pipeline components, hydraulic systems, and many more.

It’s worth noting that while spheroidal Graphite Iron excels in high-stress environments, material selection should always consider the specific requirements, operating conditions, and design considerations of the application at hand. Engineering experts and material specialists should be consulted to determine the most suitable material for a particular high-stress environment.