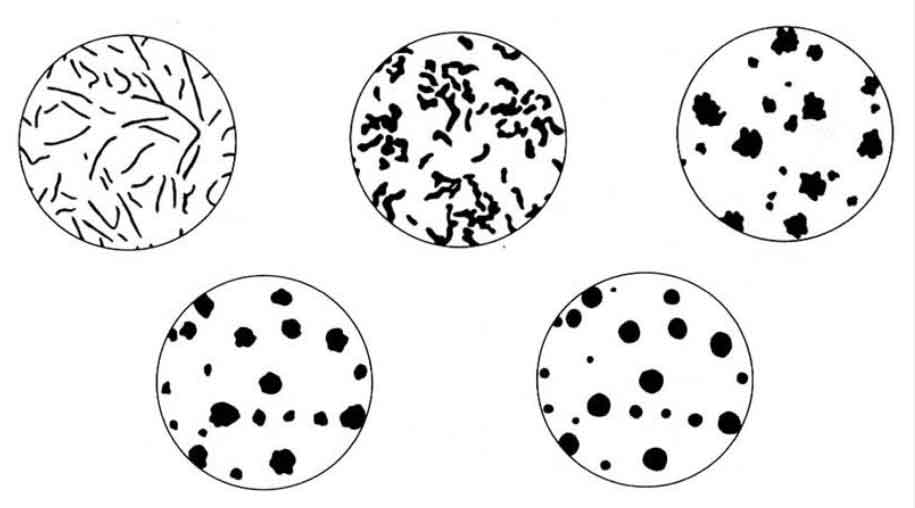

Spheroidal Graphite Iron, also known as ductile iron or nodular cast iron, is a type of cast iron that exhibits excellent strength, ductility, and versatility. It is created by adding a small amount of magnesium or cerium to molten iron before casting, which leads to the formation of graphite in a spheroidal or nodular shape, rather than the traditional flake-like graphite found in regular cast iron. This unique microstructure gives Spheroidal Graphite Iron its exceptional mechanical properties and makes it highly desirable in various applications.

Strength and Mechanical Properties: One of the key advantages of Spheroidal Graphite Iron is its impressive strength-to-weight ratio. It provides a combination of high tensile strength, yield strength, and good elongation, allowing it to withstand heavy loads and resist deformation. Compared to other cast irons, SGI typically has two to three times the tensile strength and up to 50% higher yield strength.

Versatility in Applications: The exceptional mechanical properties of Spheroidal Graphite Iron make it suitable for a wide range of applications across various industries:

- Automotive Industry: Spheroidal Graphite Iron is extensively used in the automotive sector due to its superior strength, wear resistance, and good machinability. It is commonly used for manufacturing engine components, such as cylinder blocks, cylinder heads, crankshafts, and camshafts.

- Machinery and Equipment: Spheroidal Graphite Iron is widely employed in the production of heavy machinery and equipment where high strength and durability are required. It is commonly used for manufacturing gears, gearboxes, bearing housings, machine frames, and hydraulic components.

- Pipe and Fittings: Spheroidal Graphite Iron pipes and fittings are utilized in industries such as water distribution, wastewater treatment, and agriculture. The high strength and corrosion resistance of SGI make it an ideal choice for underground or submerged applications.

- Construction and Infrastructure: Spheroidal Graphite Iron finds its application in the construction industry for manufacturing components like manhole covers, drainage grates, and other heavy-duty infrastructure elements. It offers excellent load-bearing capacity, durability, and resistance to wear and impact.

- Energy Sector: Spheroidal Graphite Iron is used in the energy industry for producing components like wind turbine hubs, rotor hubs, and hydraulic power transmission systems. Its high tensile strength and fatigue resistance make it suitable for withstanding the demanding conditions in these applications.

Spheroidal Graphite Iron combines the strength and wear resistance of cast iron with the ductility and toughness of steel, making it an exceptional material for a broad range of applications. Its versatility, coupled with its excellent mechanical properties, has positioned it as a preferred choice in industries where high strength, durability, and reliability are paramount.