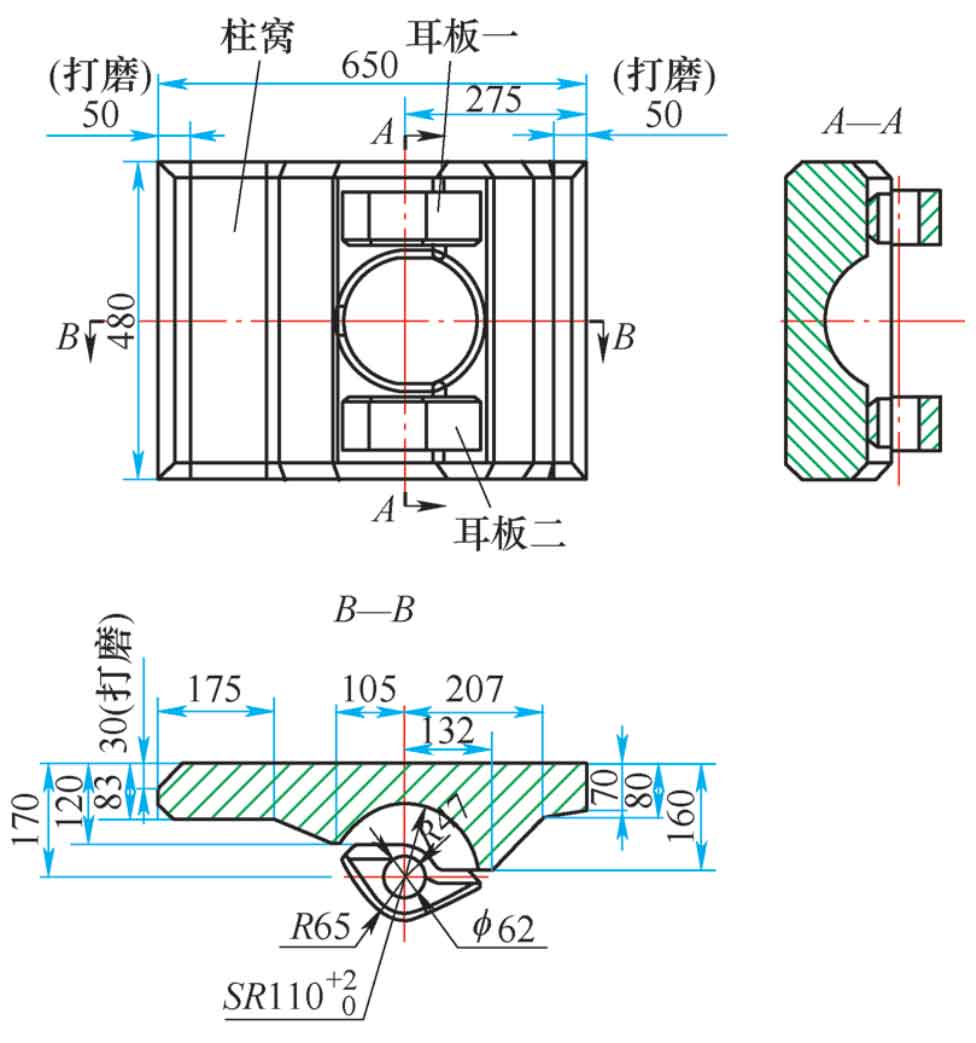

Figure 1 shows the structure of typical roof beam mining support parts, which is composed of mining support parts, ear plate I and ear plate II; Figure 2 shows the three-dimensional structure of typical roof beam mining support parts.

For the structure of the typical roof beam mining support parts, because it has two protruding ear plates, it is difficult to forge, and it also seriously reduces the die life, so the split forging method is selected, that is, the mining support parts, ear plate I, and ear plate II are divided into three parts, and then welded after forging.

Because the volume and projected area of the mining support parts are large, and the theoretical requirements for the equipment tonnage are high, the weight and projected area of the mining support parts should be reduced as much as possible in the design. In addition, because the metal flow in the forging process is not as good as that of casting, the arc transition should be increased as much as possible at the corners of each face, which can ensure that the metal is full during die forging, and can extend the service life of the die.