With the rapid development of the automotive industry, the requirements for automotive castings are getting higher and higher, and the output is increasing. According to the development experience of ZHY casting, aiming at the production of nodular cast iron automobile brake caliper castings, the process layout method to improve the yield is put forward.

1. Casting structure

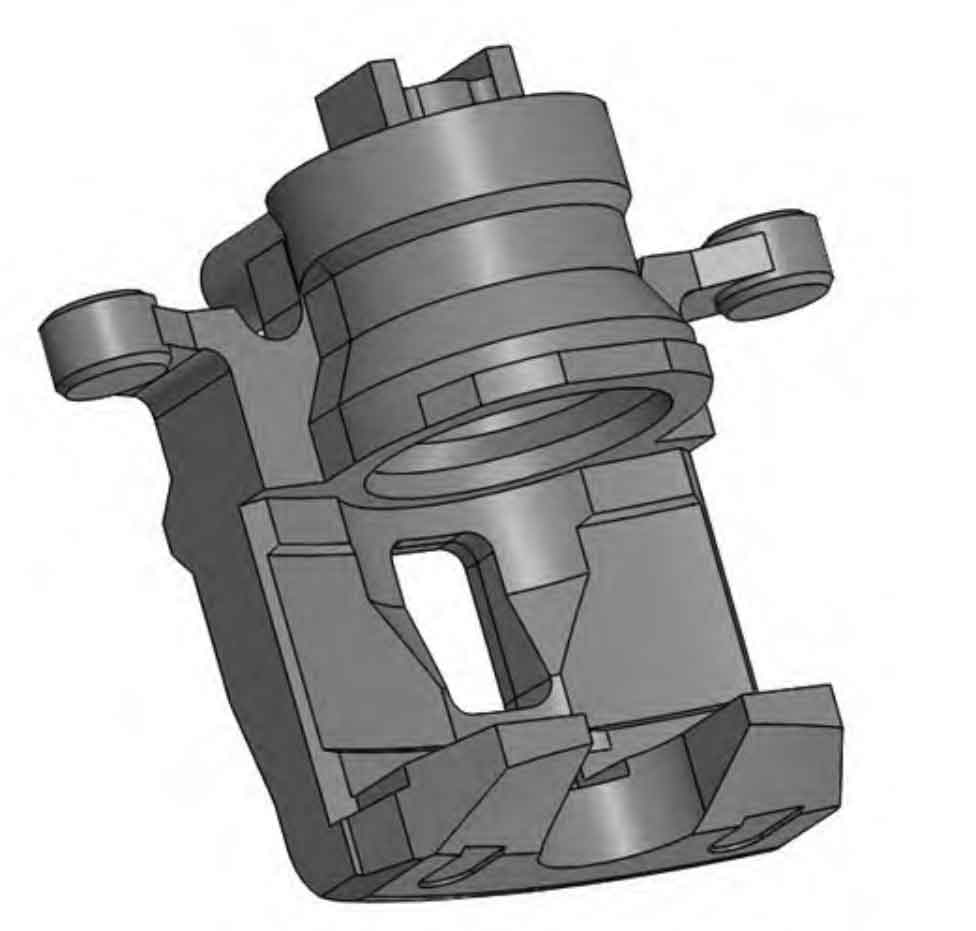

The material brand of nodular cast iron automobile brake caliper casting is QT450-10, the single weight of the casting is 3.02kg, and the overall dimension is 185mm × 74 mm × 163 mm, the casting structure is shown in the figure.

2. Technical requirements

The chemical composition requirements of nodular cast iron automobile brake caliper castings are shown in the table. The metallographic structure requires that the spheroidization rate is ≥ 80%, the graphite size is grade 5~8, and the matrix is ferrite + pearlite. Mechanical properties require tensile strength ≥ 450 MPa, yield strength ≥ 280 MPa, elongation ≥ 10%, hardness 143~217 HBW. The internal quality shall be free of shrinkage porosity, shrinkage cavity, crack and pore defects. The surface of nodular cast iron automobile brake caliper castings shall not have any sand holes, slag holes and other defects that affect the appearance and assembly.

| Element | C | Si | Mn | P | S | Cu |

| Content | 3.3-3.9 | 2.2-3.2 | 0.1-0.4 | ≤0.08 | ≤0.02 | ≤0.2 |

The automobile brake caliper is produced by the vertical parting boxless molding process. The traditional way of placing the nodular cast iron automobile brake caliper castings is to place the cylinder barrel vertically. Now, by using the way of placing the cylinder barrel horizontally, the original arrangement of 4 castings is increased to 6 castings, which improves the process yield and production efficiency, and the metallographic structure and mechanical properties of the nodular cast iron automobile brake caliper castings meet the technical requirements.