(1) Investment casting impeller blade pressing structure

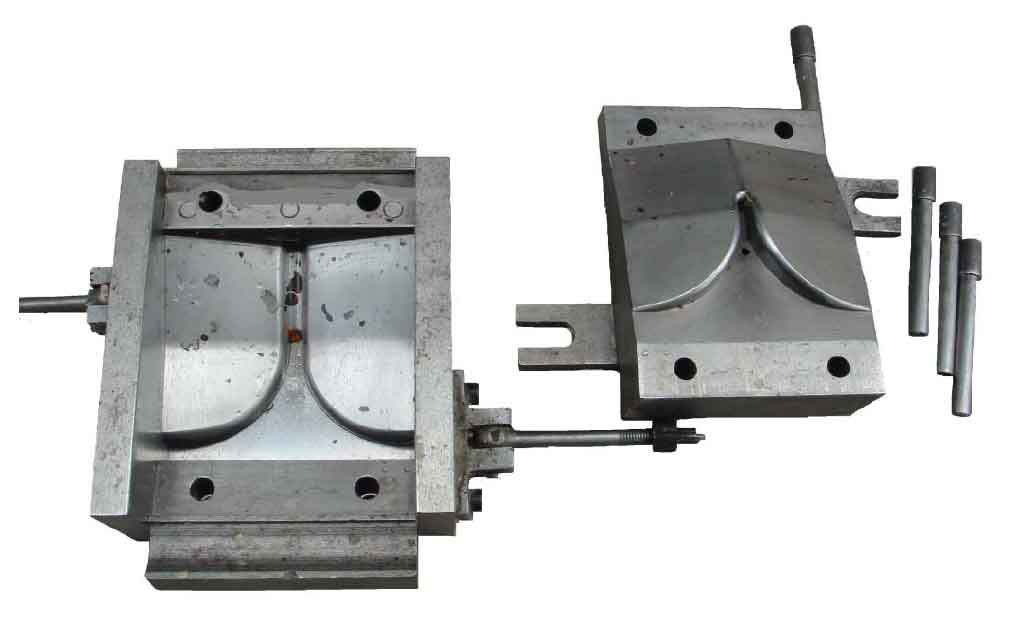

After analyzing the structure, shape, technical requirements, production conditions and economy of investment casting impeller blade, the manual investment casting impeller blade pressing structure is selected, as shown in the figure. The die is composed of upper and lower half dies. Its main components are as follows:

① Forming part: including upper pressing part and lower pressing part. In order to facilitate the lifting of the mold, part of the down pressing mold is designed to survive quickly.

② Positioning mechanism: commonly used are pin, bolt, boss, box body and other forms. This pressing adopts 4 Φ 8 to prevent the dislocation of the upper and lower pressing type and movable block during closing.

③ Wax injection port: from this port, the mold material enters the cavity. Selection of pressure mould for impeller blade in investment casting Φ 4 wax injection port of the.

④ Locking mechanism: locking nuts are commonly used. The design of this mechanism has been standardized, and its design can be found in relevant manuals.

⑤ Inner runner: because the investment casting impeller blade is used for the assembly and welding of the whole investment casting impeller blade and part of the investment mold, the inner runner is not designed.

⑥ Exhaust duct: the pressure molding structure of investment casting impeller blade is simple, and there is exhaust with movable block gap, so the exhaust duct is not specially designed.

(2) Selection and manufacture of molding materials for investment casting impeller blade

The machined profiled material is 45 steel, Quenched and quenched and tempered, and the Hb is 280 ~ 350. Dimensional accuracy and surface roughness are guaranteed by machining.