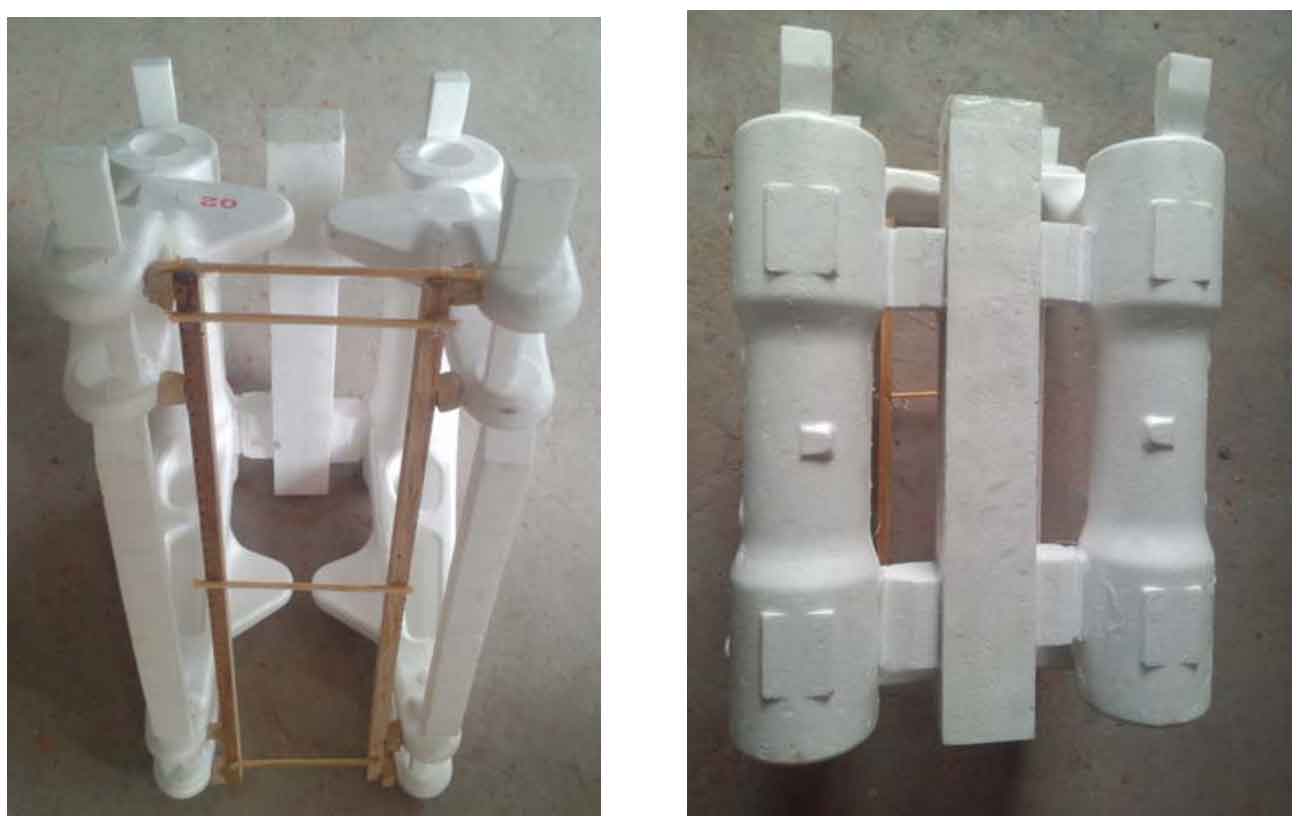

The above improvement scheme is used to verify the pouring production. Figure 1 is the foam pattern cluster and the deformation prevention treatment. The production results of the improved scheme are shown in Figure 2. No significant shrinkage defects are found when the shaft sleeve is cut open, and only a small amount of centralized shrinkage porosity exists in the lower hot spot area. The trial production results are similar to the simulation results. The improved scheme basically solves the shrinkage problem of ductile iron long fork lost foam casting and greatly reduces the degree of shrinkage porosity.

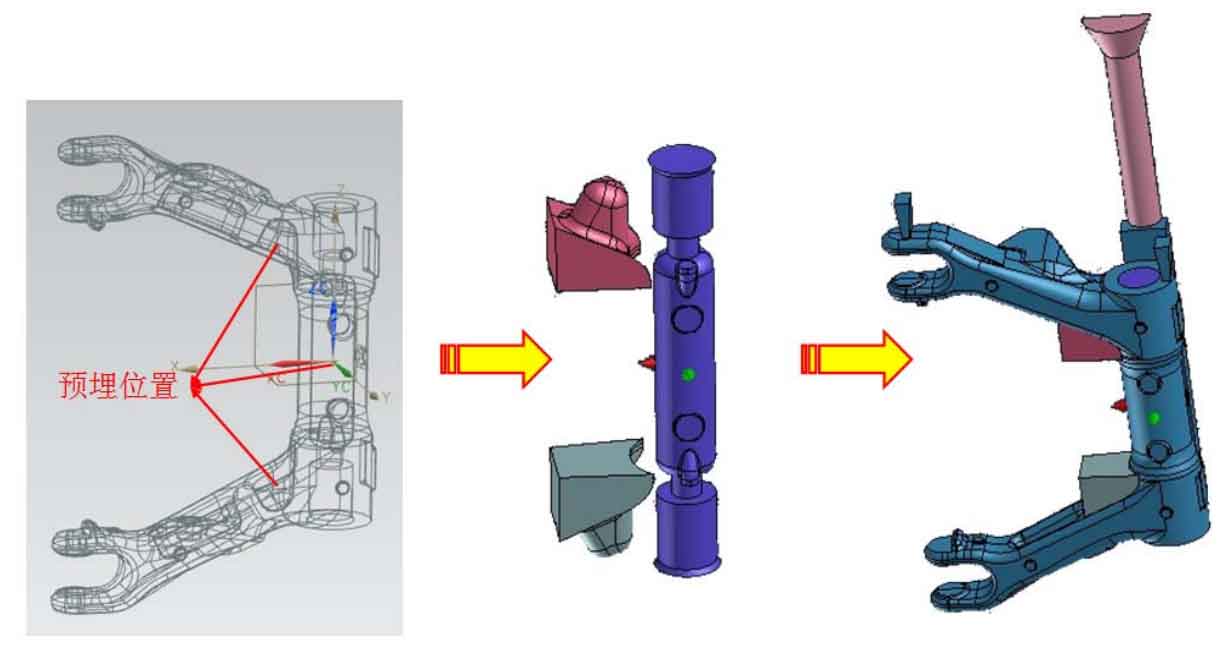

In view of the problem of a small amount of medium shrinkage cavity in the actual production of the optimized process and the influence of different sand types on the shrinkage cavity and porosity of nodular cast iron long fork lost foam casting, the new process can be supplemented by pre embedding ferrochrome cold sand near the hot joint of nodular cast iron long fork lost foam casting, as shown in Figure 3.

Ferrochrome cold sand can not only change the local temperature field of ductile iron long fork lost foam casting, promote the feeding in this area, but also refine the grain. Moreover, ferrochrome cold sand is magnetic, which can be recycled by magnetic separation, can be reused and has low cost. At the same time, through the embedded treatment, the hidden dangers that may have been filled with dry sand before, such as wall sockets and step holes, have also been successfully eliminated. The practice shows that the supplementary process can finally solve the problem of significant shrinkage, minimize the shrinkage porosity, and obtain the long fork lost foam casting of nodular cast iron with good internal and external quality.