Porosity is a common problem in sand casting that can affect the final product’s performance and appearance. To maintain high quality, it is essential to detect and measure porosity in the produced parts. This article will explore several techniques commonly used for this purpose.

Visual Inspection: The simplest method to detect porosity is through visual inspection. Surface porosity often results in a pitted or rough appearance, which can be seen with the naked eye. However, this method can only detect surface porosity and cannot determine the extent of subsurface or internal porosity.

Dye Penetrant Inspection: Dye penetrant inspection is a non-destructive testing (NDT) method commonly used to detect surface porosity. The cast part is coated with a dye, which penetrates into any surface pores. The excess dye is then removed, and a developer is applied, which draws the dye out of the pores, making them visible.

Radiographic Inspection: Radiographic inspection, or x-ray testing, is an NDT method used to detect internal porosity. This method involves exposing the part to x-rays or gamma rays, which are then captured on a detector after passing through the part. Areas with porosity will appear darker on the radiograph because they are less dense and absorb fewer rays.

Ultrasonic Inspection: Ultrasonic inspection uses high-frequency sound waves to detect internal flaws such as porosity. A transducer sends sound waves into the part, which are reflected back when they hit a flaw. By analyzing these reflections, the size and location of the pores can be determined.

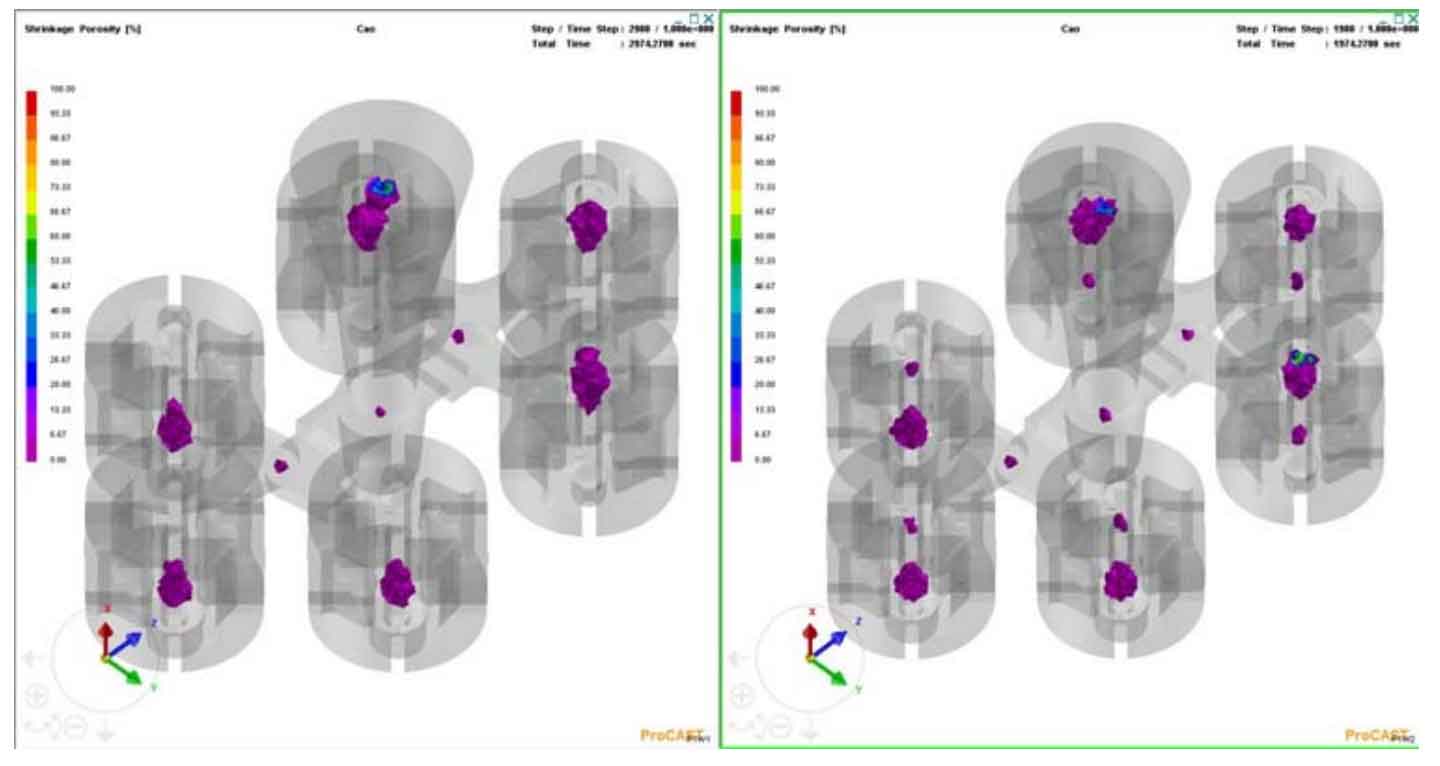

Computed Tomography (CT): Computed tomography, similar to radiographic inspection, uses x-rays to create a detailed three-dimensional image of the part. This method provides a more detailed view of the internal structure of the part and can provide precise measurements of porosity.

Metallographic Examination: Metallographic examination involves taking a small sample from the casting and preparing it for microscopic examination. This destructive testing method can provide detailed information about the size, shape, and distribution of pores.

Detecting and measuring porosity is essential for maintaining the quality of sand castings. The selection of the right method depends on various factors, such as the casting’s size and material, the expected size of the pores, and whether the inspection is for quality control or failure analysis. It is crucial to note that while non-destructive testing methods can provide valuable insights, in some cases, destructive testing may be necessary for a more detailed understanding.