1. Test materials and preparation

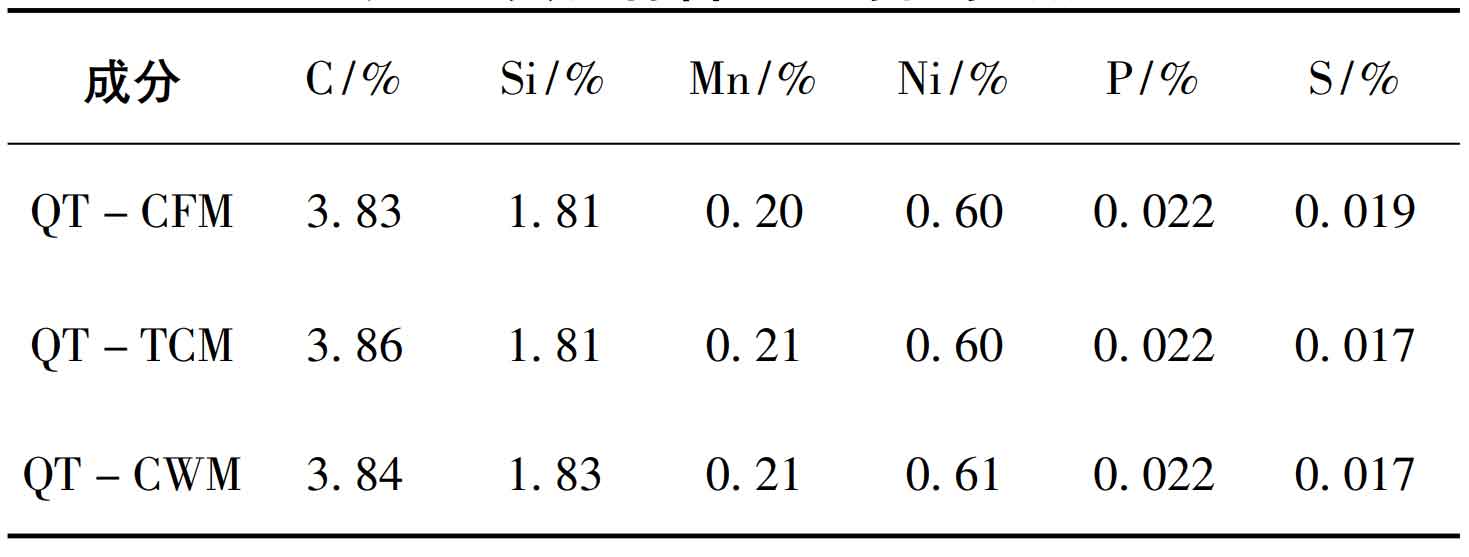

The composition of three groups of nodular cast iron samples is self-designed, and the specific chemical composition is shown in the table. In addition to the elements shown in the table, the residual is Fe, in which WSI / WC is about 0.5% 48, in line with a better ratio. Three groups of nodular cast iron samples adopt different spheroidizing processes. Nodular cast iron sample 1 adopts the traditional punching method (qt-cfm), nodular cast iron sample 2 adopts the covering method (qt-tcm), and nodular cast iron sample 3 adopts the wire feeding method (qt-cwm). Three groups of ductile iron samples were annealed at 920 ℃ for 1 h after casting. The microstructure was observed and analyzed by Hitachi s-3400n scanning electron microscope.

2. Performance test

Hardness test is to take 5 points evenly distributed on the surface of nodular cast iron sample for test, and take the average value of each group of data to obtain Brinell hardness value. The yield strength and tensile strength shall be tested for 3 times by universal tensile machine, and the average value shall be taken.

The impact test is to cool the ductile iron sample to – 25 ℃ under the condition of liquid nitrogen according to the national standard gb229-2002. Three samples are taken from each group, and the average value of impact energy is taken. The figure shows the real object of the standard impact sample. The fracture morphology was analyzed by Japanese Hitachi s-3400n scanning electron microscope.