1. Test materials

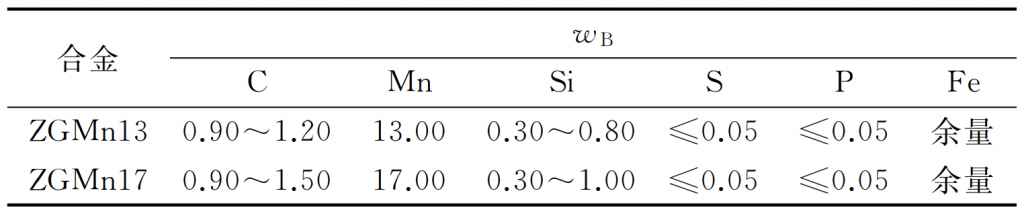

The test materials are as cast ZGMn13 high manganese steel and zgmn17 ultra-high manganese steel wear-resistant lining plate, which are produced by lost foam casting process (see Figure 1). The ultra-high manganese steel wear-resistant lining plate needs to be used under medium and low impact conditions for a long time. The expected service hours are 4200h. See Table 1 for its chemical composition. The medium frequency furnace is used for smelting. A small amount of rare earth powder is added before tapping. After complete melting, a small amount of Al powder is added for deoxidation, slag accumulating agent is added in batches, and slag raking is carried out in batches after slag accumulating. The pouring temperature is 1480 ℃, the pouring time is about 130s, and the box is opened after 8h.

2. Test method

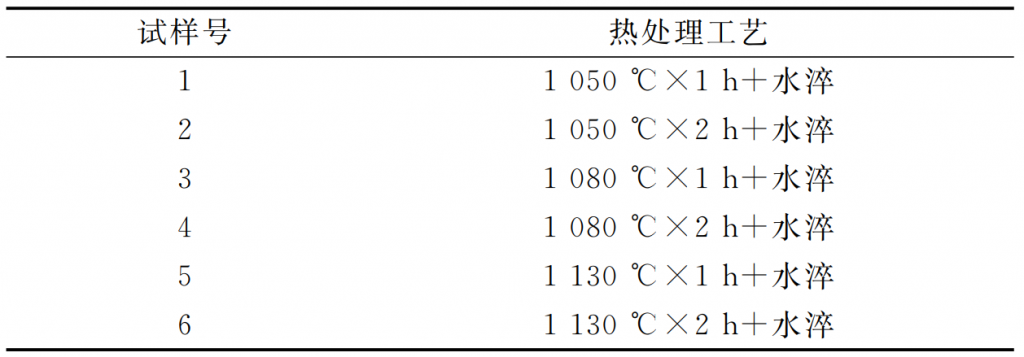

The ZGMn13 and zgmn17 high manganese steel wear-resistant lining plates cast by EPC are subject to different heat treatments. The test scheme is shown in Table 2, in which the water quenching medium is industrial NaCl solution. According to the iron carbon phase diagram, the water toughness temperature of ZGMn13 and zgmn17 shall be 150 ~ 200 ℃ higher than the starting line of austenitizing temperature. The holding time shall be determined according to the thickness and experience of high manganese steel wear-resistant lining plate. After reaching the preset holding time, it shall be discharged from the furnace and quickly moved into the water tank to ensure that the water inlet temperature of high manganese steel wear-resistant lining plate is not lower than 950 ℃, Ensure to obtain single austenite structure, avoid grain boundary network carbide and reduce the impact toughness of high manganese steel wear-resistant lining plate. Therefore, the water toughening treatment temperature is 1050, 1080 and 1130 ℃, and the holding time is 1H and 2H. After the water toughening treatment, the required metallographic samples are prepared by wire cutting, polished by Phoenix 4000 polishing mill, corroded with 4% nitric acid alcohol solution, and the microstructure is observed on the metallographic microscope (axioscope. A1). Use fm-ars-9000 microhardness tester to measure the hardness value of the sample. The applied load is 2n and the loading time is 10s. Take the average value of the three test data.