1. Test results

| Workmanship | Standards | Tensile strength (≥ 655)/MPa | Yield strength (≥ 551)/MPa | Elongation (≥ 18)/% | Reduction of area (≥ 35)/% |

| Process 1 | Measured value 1 | 692.9 | 563.8 | 24.6 | 70 |

| Process 1 | Measured value 2 | 682.3 | 564.1 | 23.8 | 70 |

| Process 2 | Measured value 1 | 677.1 | 561.5 | 24.06 | 68.9 |

| Process 2 | Measured value 2 | 684.6 | 563.1 | 23.46 | 61.7 |

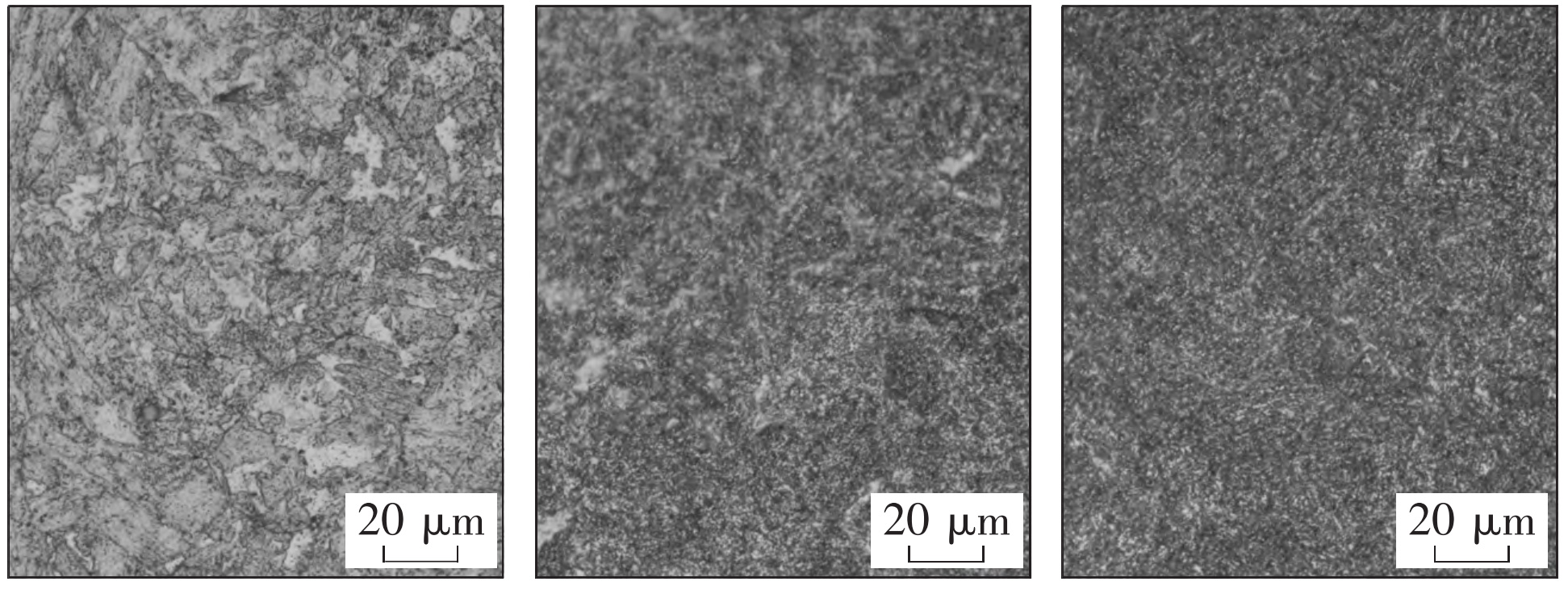

The welding process for quality heat treatment after welding (referred to as process 1) and the welding process for stress relief heat treatment after welding in the quenched state (referred to as process 2). According to the process and inspection specifications, the performance results of steel castings after welding are shown in Table 1, the hardness test values of steel castings are shown in Table 2, the impact energy test results are shown in Table 3, and the metallographic structure of process 2 welds is shown in the figure.

| Hardness (HV) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Process 1 | 210 | 208 | 224 | 213 | 208 | 225 | 220 | 209 | 217 | 210 |

| Process 2 | 208 | 217 | 209 | 242 | 247 | 212 | 207 | 210 | 217 | 215 |

| Hardness (HV) | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| Process 1 | 215 | 211 | 211 | 213 | 224 | 214 | 214 | 207 | 216 |

| Process 2 | 210 | 248 | 249 | 218 | 216 | 227 | 210 | 236 | 210 |

2. Result Analysis

From the experimental results, it can be seen that both process 1 and process 2 can meet the performance requirements of the welding site. The quenching and tempering heat treatment was carried out after the welding of process 1, the microstructure of the weld zone of the steel casting was refined, the hardness range of the three zones was small, the toughness of the weld zone was significantly improved, and the impact energy of the Heat-affected zone was more abundant. After welding in process 2, the post weld stress relief heat treatment at 20 ℃ lower than the tempering temperature is carried out. The hardness range of the weld zone of the steel casting is large, and the hardness of the Heat-affected zone is lower than the weld bead. Because the heating temperature of the Heat-affected zone is higher than the tempering temperature of the base metal to the area of Ac1 when the steel casting is welded, the steel is softened due to the accumulation and growth of carbides, which indicates that the residence time near the Ac1 temperature range should be minimized in the actual process. As shown in the figure, the metallographic test results show that the microstructure of process 2 weld is columnar crystal, the original austenite grain boundary is clear, and it is mainly a mixed structure of martensite+bainite+ferrite. Fig. b) It can be seen that the heat affected structure is Flat noodles martensite+a small amount of tempered troostite (white). This is because the backing pass adopts small heat input, multi-layer and multi pass welding, and when the inter pass temperature of the steel casting is controlled between 150 ℃ and 200 ℃, the base metal in the Heat-affected zone is formed by repeated heating. At the same time, the carbide in the Heat-affected zone will segregate at the edge of troostite. At this time, the impact toughness of the Heat-affected zone will be reduced. The base metal is uniform Flat noodles martensite structure.

Two different processes correspond to the welding of steel castings in different heat treatment states of the base material, which can be used in the production of blowout preventers, and the obtained toughness and hardness can also meet customer requirements.