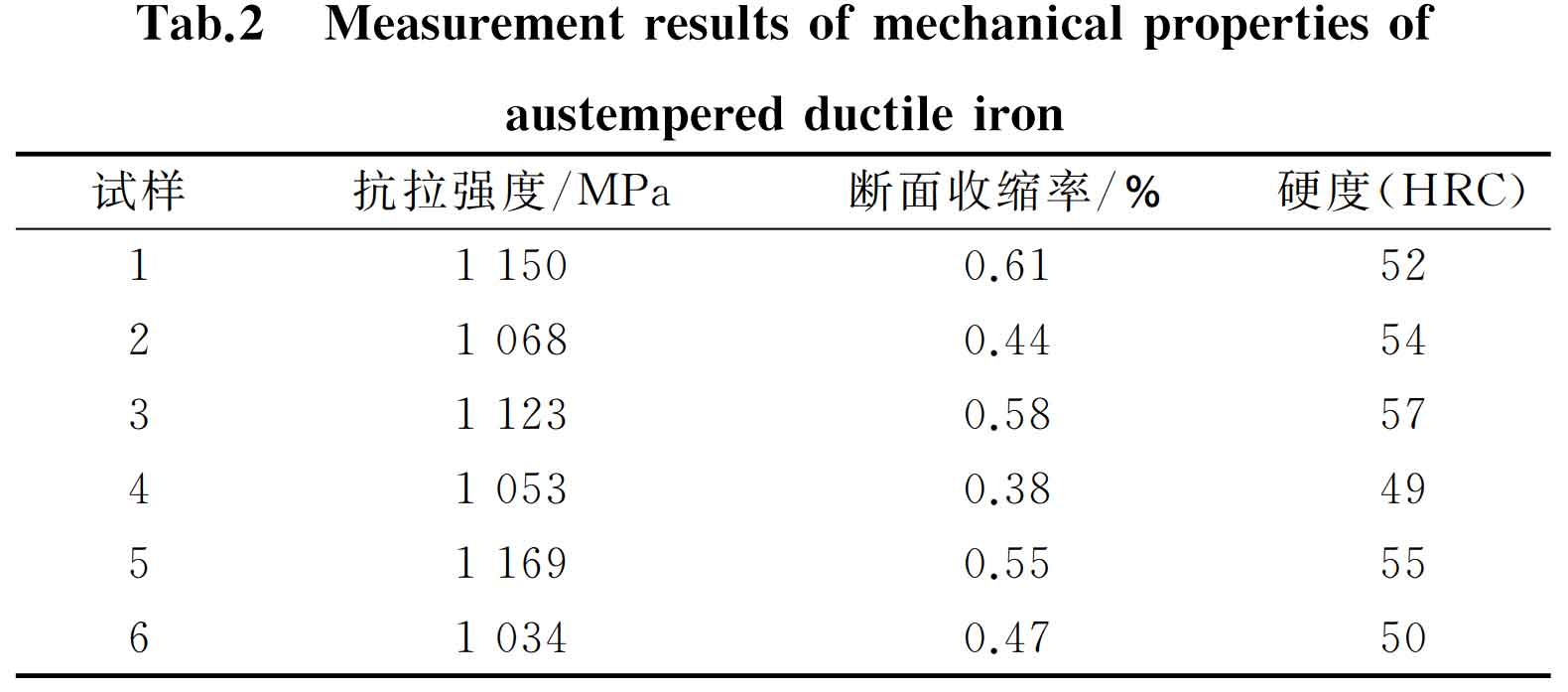

Six groups of samples were selected and tested for mechanical properties by wav-600a universal testing machine. The results are shown in Table 1. It can be seen that the average tensile strength is 1099mpa, the average reduction of area is 0.5%, and the average hardness (HRC) is 52.8.

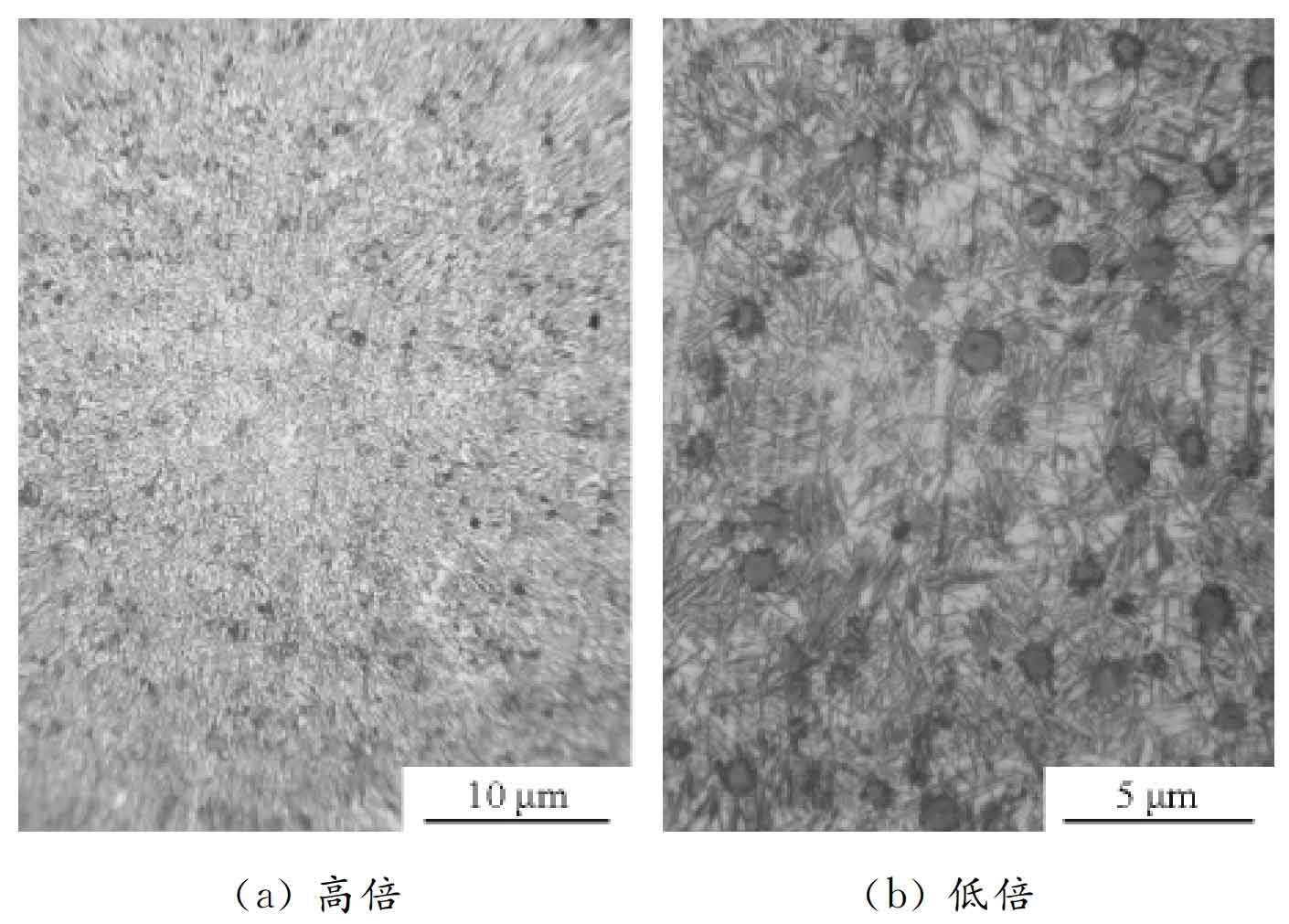

The metallographic structure of Austempered duct iron treated bushing is shown in Figure 1. According to the hardness test results, the microstructure of austempered ductile iron is mainly composed of acicular lower bainite, spherical graphite, retained austenite and a small amount of martensite. Among them, there are many spherical graphite with round shape and uniform size. Retained austenite is evenly distributed and connected to form matrix.

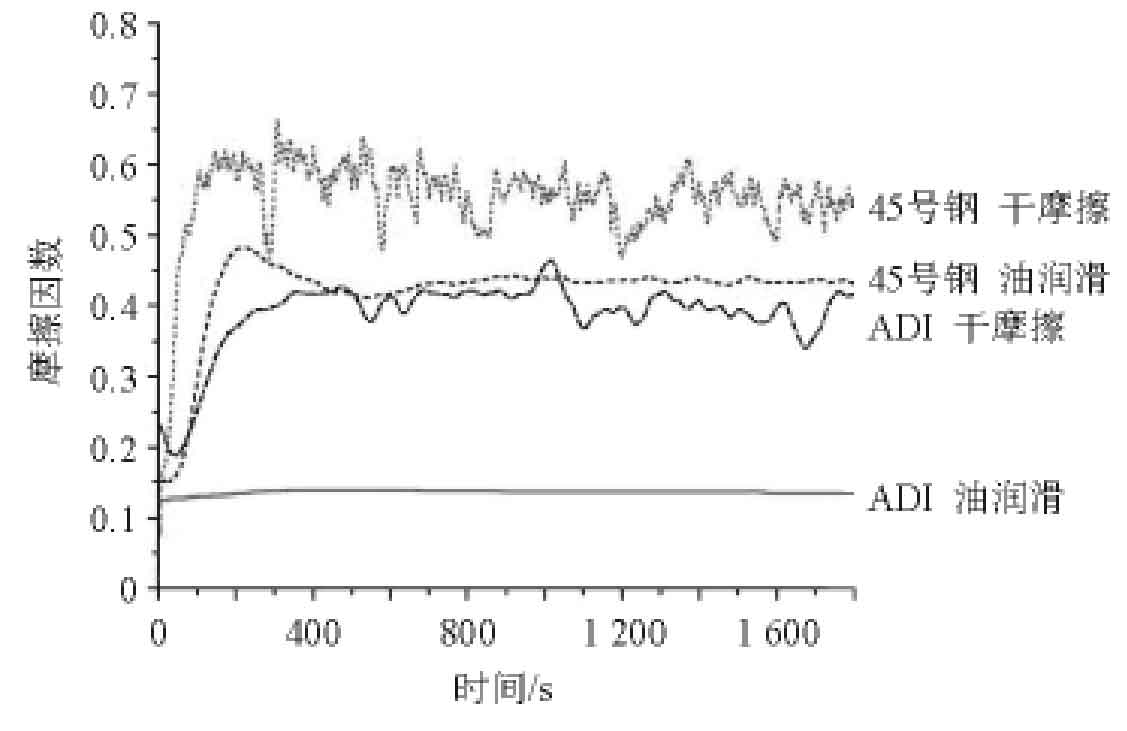

The friction coefficient of Austempered Dutile iron treated sample and 45 steel sample under dry friction and oil lubrication is shown in Figure 2. It can be seen that the sample increases rapidly at the initial stage of wear, and the friction coefficient of austempered ductile iron sample is more gentle than that of 45 steel. Among them, 45 steel has the highest friction coefficient under dry friction, which is about 0.58; The friction coefficient of Austempered Dutile iron sample under oil lubrication is the lowest, about 0.12. It can be found that the friction coefficient of Austempered Dutile iron sample under dry friction condition is about 2 / 3 of that of 45 steel, while that of ADI sample under oil lubrication condition is only 1 / 4 of that of 45 steel.

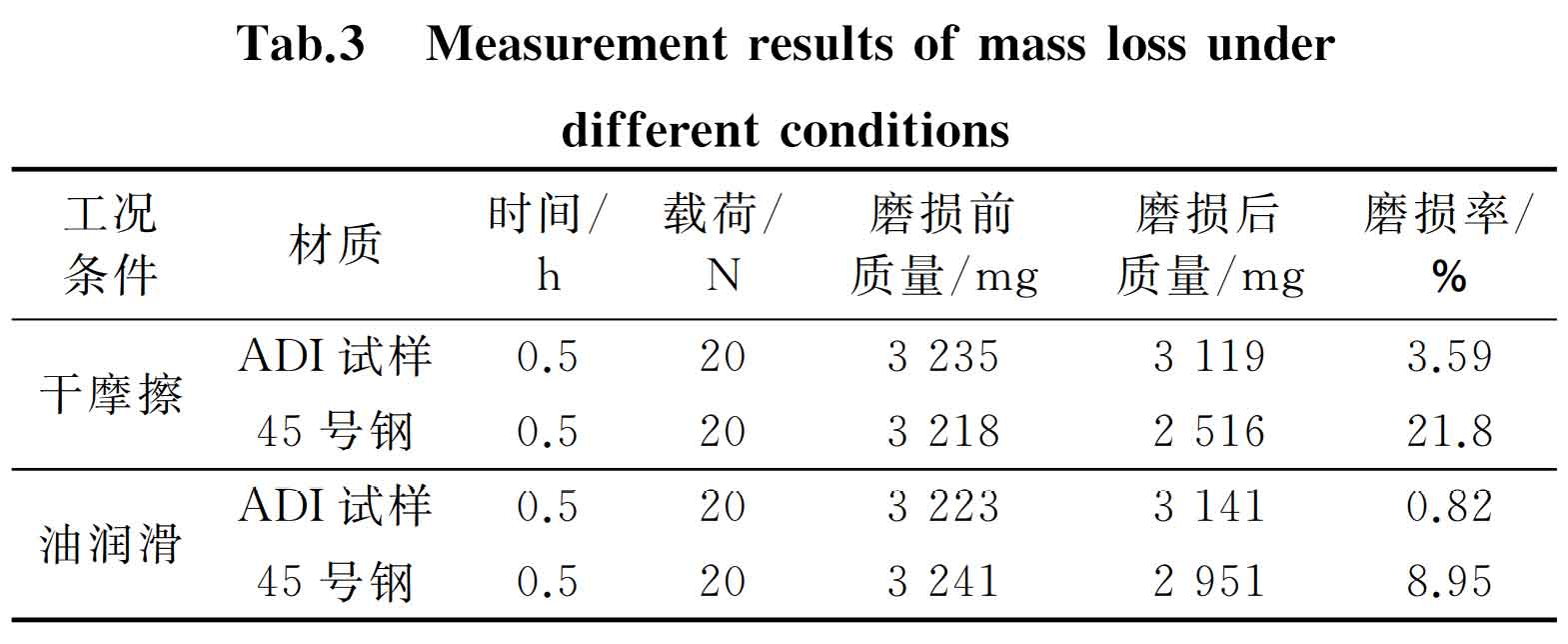

Measure the mass of each sample before and after wear, and calculate the wear mass loss of the sample. See Table 2 for the results. It can be seen that the wear amount of Austempered Dutile iron specimen under both conditions is much less than that of 45 steel. Under the condition of dry friction, the wear rate of Austempered duct iron is 3.59%, and the wear amount is about 1 / 6 of that of 45 steel. Under the condition of oil lubrication, the wear rate of Austempered duct iron is only 0.82%, and the wear amount is only 1 / 10 of that of 45 steel. It can be seen that the lubrication condition can reduce the friction coefficient and wear under the two working conditions, but the antifriction effect of lubrication on Austempered Dutile iron sample is more obvious.