Abstract

Based on the exhaust process design of the pouring system for cylinder block castings, this paper explores methods to effectively solve the issue of exhaust during the casting process and reduce defects such as blowholes in the castings. By employing techniques such as hollowing out thick and large sand cores to reduce their weight, and considering the exhaust and feeding capabilities of both the sand mold and sand core in conjunction with the casting structure and molding process, we aim to enhance the quality of cylinder block castings.

Keywords: cylinder block casting; sand core emptying; exhaust channel; blowhole

1. Introduction

Cylinder block castings are crucial components in internal combustion engines, and their quality directly impacts the performance and reliability of the engine. However, porosity defects are common in cylinder block castings, particularly during the green sand molding and gray iron casting process. The gases that produce these pores mainly originate from the molten iron and the decomposition of organics within the sand cores at high temperatures. This paper focuses on the design of the exhaust process for cylinder block castings, aiming to reduce porosity defects and improve casting quality.

2. Analysis of Casting Defects and Prevention Measures

2.1 Causes of Blowholes in Cylinder Block Castings

Blowholes are one of the most common defects in castings. During the green sand molding process for gray iron castings, the gases that produce these blowholes mainly come from two sources: the molten iron and the decomposition of organics within the sand cores. As cylinder block castings often consist of numerous sand cores, with a total weight exceeding 350 kg, the inability to efficiently vent the gases generated from these sand cores increases the likelihood of blowhole defects, leading to quality losses and waste.

Table 1: Causes of Blowholes in Cylinder Block Castings

| Cause | Description |

|---|---|

| Molten Iron | Gases dissolved in the molten iron that escape during solidification |

| Sand Core Organics | Decomposition of organics within the sand cores at high temperatures |

2.2 Prevention Measures

To address this issue, the exhaust process design for cylinder block castings can be approached from three aspects: reducing the weight of sand cores to decrease gas generation, designing exhaust channels within sand cores, and designing exhaust structures for the sand mold.

3. Design of the Exhaust Process for Cylinder Block Castings

3.1 Reducing Sand Core Weight to Decrease Gas Generation

Under the premise of ensuring sand core structure integrity and strength against molten iron erosion, the design of hollow structures within thick sand cores can be adopted to reduce their weight and, consequently, the amount of gas generated.

For sand cores with large volumes, such as those for the cylinder block body,掏空 designs can be implemented to reduce weight. Additionally, to maintain the fluidity of sand injection during the core-making process, follow-the-shape designs can be employed, avoiding the locations of sand injection holes.

Table 2: Comparison of Sand Core Weights Before and After Hollowing

| Sand Core Type | Original Weight (kg) | Hollowed Weight (kg) | Weight Reduction (%) |

|---|---|---|---|

| Cylinder Block Body Core | 296×64×H | 230×60×(H-100) | ~20 |

3.2 Design of Exhaust Channels Within Sand Cores

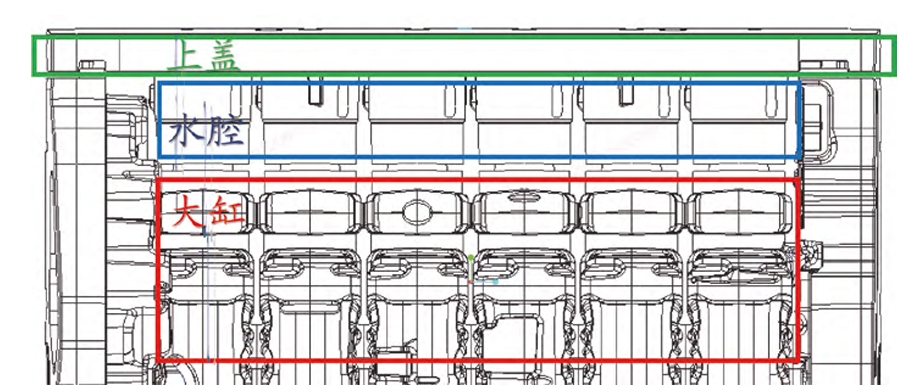

During the manufacturing of cylinder block castings, the large sand cores, including those for the large cylinder, water jacket, and upper cover, account for 95.6% of the total volume. To efficiently vent the gases generated during pouring, cylindrical exhaust channels can be set in the centers of these sand cores.

The gases generated during pouring can flow through these channels and be expelled outside the mold through exhaust vents and needles on the outer parting surfaces of the sand cores.

3.3 Design of Exhaust Structures for the Sand Mold

Although green sand molds have inherent permeability, it is insufficient for the rapid venting of gases generated during pouring. Therefore, exhaust channels need to be designed within the sand mold.

The exhaust structures can be classified into bright and dark types based on their exposure to the external environment. The choice of exhaust structure type depends on the casting structure and severity of defects.

Table 3: Types of Exhaust Structures

| Type | Description | Application |

|---|---|---|

| Bright | Exhaust channels directly exposed to the external environment | Suitable for areas with easy access and less interference |

| Dark | Exhaust channels separated from the external environment by sand mold material | Suitable for areas with limited space or high interference |

4. Case Study and Analysis

A case study was conducted on a cylinder block casting to evaluate the effectiveness of the proposed exhaust process design. By implementing hollow designs within thick sand cores, designing exhaust channels within sand cores, and incorporating exhaust structures within the sand mold, the issue of gas venting during pouring was significantly improved.

Table 4: Comparison of Casting Quality Before and After Applying the Exhaust Process Design

| Quality Indicator | Before Design Implementation | After Design Implementation |

|---|---|---|

| Blowhole Defect Rate | High | Significantly Reduced |

| Casting Surface Quality | Poor in Some Areas | Improved Overall |

| Casting Dimensional Accuracy | Some Deviations | Improved Accuracy |

5. Conclusion

The exhaust process design for cylinder block castings is crucial for improving casting quality and reducing defects such as blowholes. By reducing sand core weight to decrease gas generation, designing exhaust channels within sand cores, and incorporating exhaust structures within the sand mold, we can effectively address the issue of gas venting during pouring. The interactive application of these three exhaust processes can significantly enhance the quality of cylinder block castings.