The core technology of investment casting of superalloy is the optimization and preparation process of core and shell material system. China’s investment casting of superalloys started from the wet molding process of paraffin – stearic acid mold material and water glass – quartz shell plus bauxite cement introduced from the Soviet Union in the 1950s.

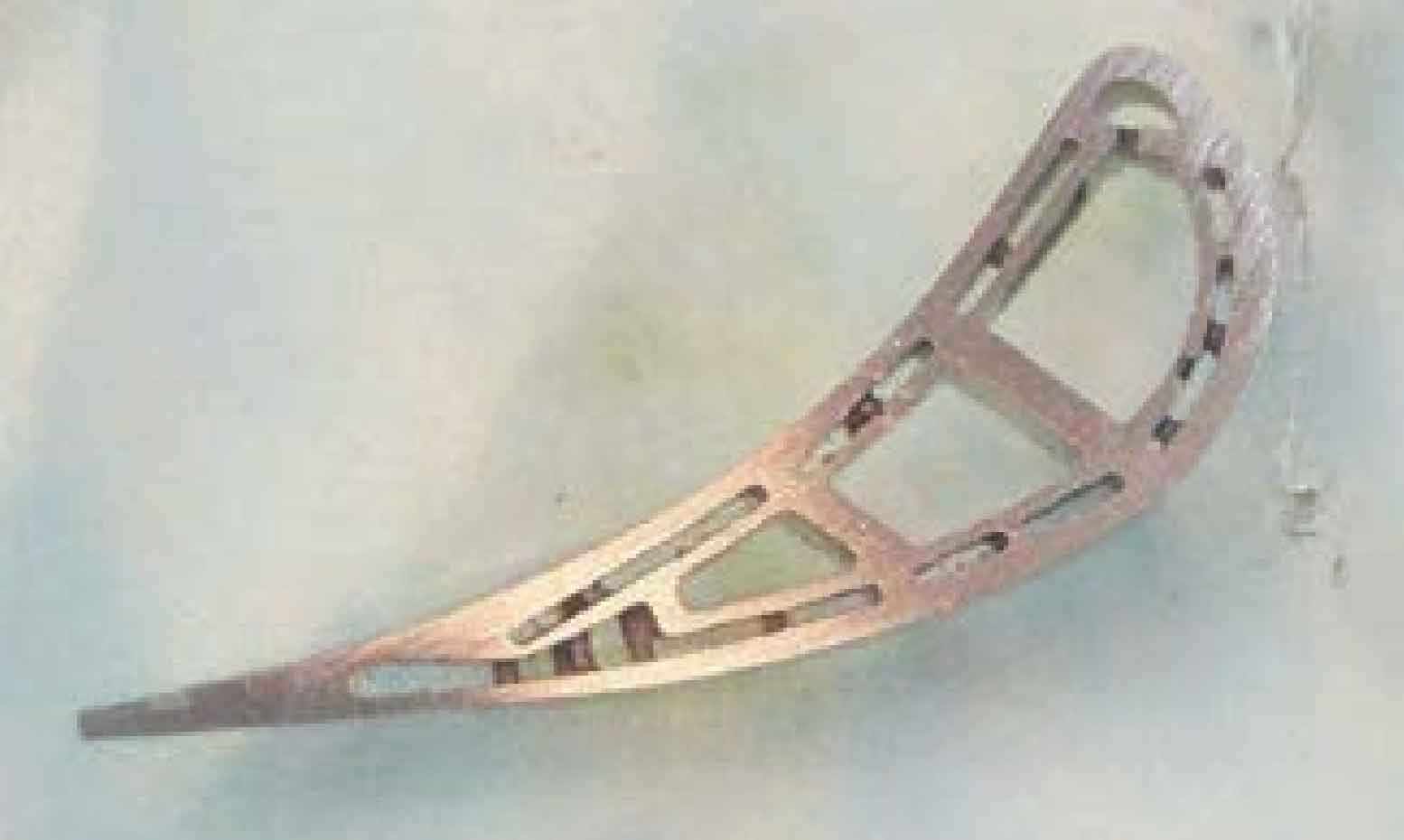

In 1965, the Beijing Institute of Aeronautical Materials successfully cast the WP – 6 engine superalloy turbine blade using this process, and then the Beijing Institute of Aeronautical Materials successively developed the quartz sand – water glass system, alumina – ethyl silicate system, alumina – silica sol system, bauxite – silica sol system and kaolin clinker – silica sol system shell. In 1966, K147 was used to cast the superalloy Multi-layer shell mold and quartz glass tube core technology are used to cast hollow turbine blades with 9 small holes (see Figure 1) for WP – 7 engines, thus opening the history of investment casting hollow turbine blades in China.

In 1975, China introduced the manufacturing technology of Spey aero-engine from the United Kingdom, realized the localization of investment casting process materials in the process of digestion and absorption, and successfully cast the low-pressure first stage hollow guide vane in the late 1970s, realizing the one-time precision forming and manufacturing of aero-engine turbine blades from solid to hollow, and then to complex inner cavities. In terms of directional and single crystal blades, Beijing Institute of Aeronautical Materials has successfully developed 811A, 811B and 811C series ceramic shells using Al-Si-Ca and Al-Si-Mg as mineralizers, which can work stably for 1~2h at 1550~1600 ℃ and can be used for forming and manufacturing 150 mm × 600mm large and complex equiaxed blade, the minimum formed wall thickness is 0.3~0.6mm, and the surface roughness Ra of investment casting can reach 1.6 μ m. The profile accuracy of the profile is ± 0.13mm, which ensures the technological requirements of the investment casting production of various blades, and meets the successful development of the directional hollow non-allowance turbine blades, single crystal blades, and equiaxed crystal blades (see Figure 2).

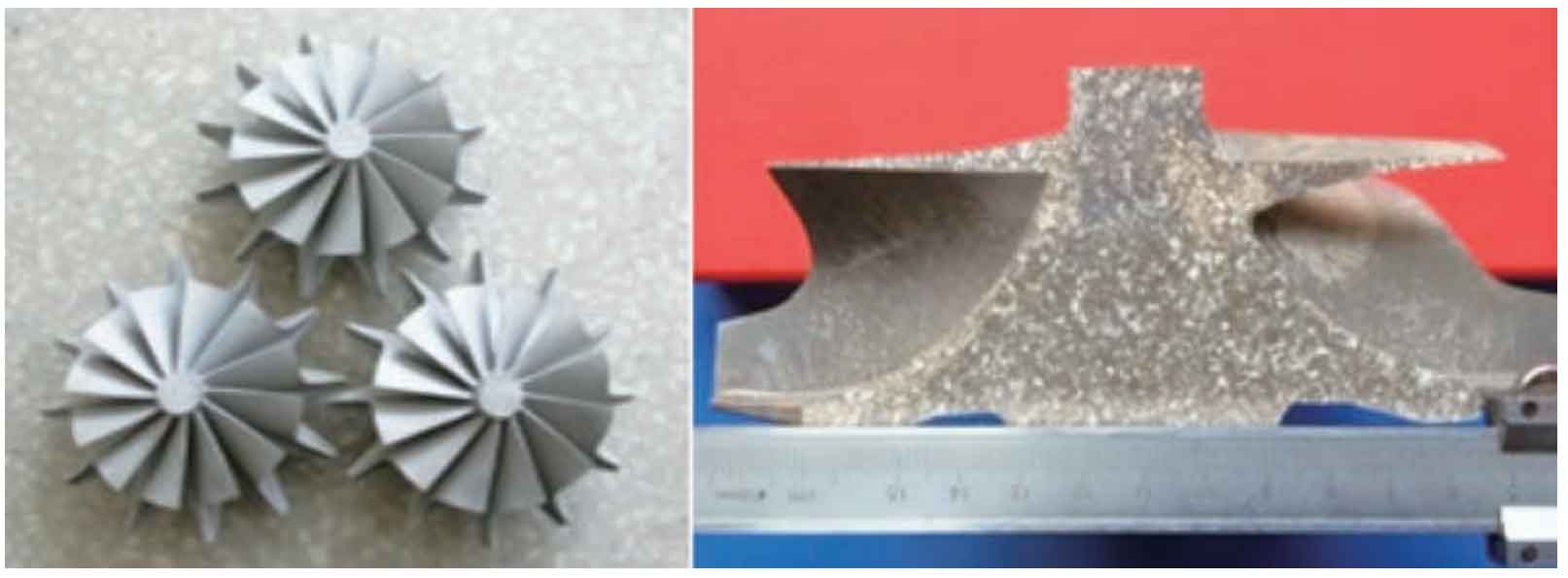

The mullite-corundum shell with high temperature resistance and higher strength was prepared by using ASM – Cr as mineralizer, low sodium silica sol as binder and fused corundum as refractory powder, which can be used for precision forming of high melting point single crystal superalloy blades. In recent years, the Beijing Institute of Aeronautical Materials and the Institute of Metals of the Chinese Academy of Sciences have also made continuous breakthroughs in the overall preparation technology of large size blade fine grains, and successfully manufactured φ The 380mm fine-grained integrated bladed disc (see Fig. 3-4), with the grain size of the hub being ASTM 2~3 and the grain size of the blade being ASTM 3~5, has achieved a breakthrough in the technical bottleneck of the failure of the starter impeller due to the fracture of the engine bladed disc blade, and the service life of the fine-grained integrated bladed disc has been significantly improved. In terms of core, the core used for investment casting of superalloy in China mainly includes XD series zircon – quartz glass ceramic core, AC series alumina ceramic core and BRA series alumina base ceramic core.

Beijing Institute of Aeronautical Materials has achieved one-time complete sintering of ceramic core with resistance to 1500~1620 ℃ by adding a new ultra-fine nanometer mineralizer, and the shrinkage rate is controlled at about 0.4%. In combination with Al2O3 – SiO2 – Na2O system high-temperature resistant ceramic shell with mullite as the main strengthening phase, the ceramic core/shell with double-wall structure has been prepared, and the investment casting of single-crystal blade with double-wall structure has been successfully achieved, as shown in Figure 5. In recent years, the Beijing Institute of Aeronautical Materials has developed a dual-orientation control method with its own characteristics in the process of single crystal blades.