Casting shrinkage is a critical consideration in the metal casting process, and optimizing the casting parameters is key to reducing shrinkage defects. This article delves into the influence of various casting parameters on shrinkage and highlights strategies to optimize the casting process for shrinkage reduction.

- Casting Temperature: The casting temperature has a significant impact on shrinkage. Higher temperatures result in increased liquid volume and longer solidification times, which can lead to higher levels of shrinkage. By carefully controlling the casting temperature, it is possible to minimize shrinkage and achieve more uniform solidification.

- Mold Material and Design: The choice of mold material and design plays a crucial role in shrinkage control. Different mold materials have varying thermal properties, which can affect the cooling rate and shrinkage behavior. Optimize the mold design to promote uniform cooling and reduce thermal gradients, which can contribute to shrinkage defects.

- Gating System Design: The design of the gating system influences the flow of molten metal into the mold cavity. Properly designed gating systems help control the filling pattern and ensure adequate feeding, reducing the risk of shrinkage defects. Consider factors such as gate size, shape, and location to optimize the flow and minimize shrinkage.

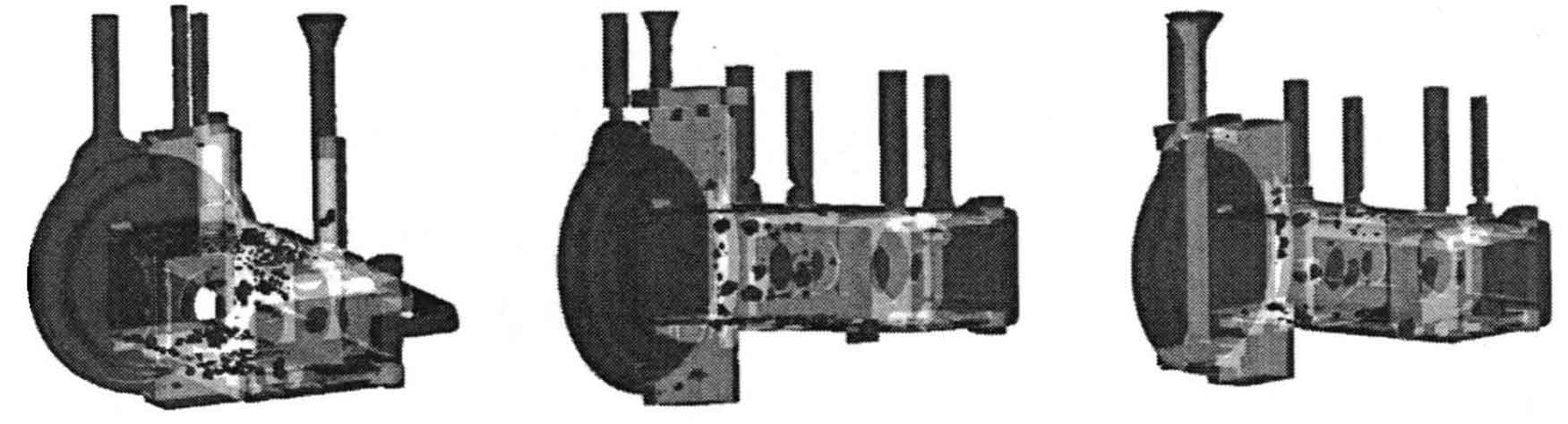

- Riser Design: Riser design is critical for effective feeding and minimizing shrinkage defects. Well-designed risers act as reservoirs of molten metal, compensating for the shrinkage that occurs during solidification. Optimize the size, shape, and placement of risers to promote efficient feeding and minimize shrinkage-related issues.

- Cooling Rate: The cooling rate during solidification has a direct impact on shrinkage. Rapid cooling can lead to increased shrinkage due to shorter solidification times, while slow cooling can result in larger grain structures and potential shrinkage defects. Controlling the cooling rate through proper mold design, use of chill plates, or controlled cooling techniques can help mitigate shrinkage.

- Pouring Time: The duration of the pouring process affects the solidification time and, consequently, the shrinkage. Longer pouring times can lead to increased shrinkage as more time is available for volume reduction. Optimizing the pouring time based on the casting geometry and material properties is essential to control shrinkage.

- Material Composition: The composition of the casting material influences its solidification characteristics and shrinkage behavior. Alloy compositions with lower solidification shrinkage tendencies can help minimize shrinkage defects. Collaborate with material suppliers and conduct proper material testing to select alloys with favorable shrinkage properties.

- Process Monitoring and Control: Implementing robust process monitoring and control systems is crucial for shrinkage reduction. Real-time monitoring of process parameters such as temperature, flow rates, and cooling rates can help identify deviations and take corrective actions promptly. Utilize data-driven approaches, such as statistical process control, to identify trends and optimize the casting process for shrinkage reduction.

- Simulation and Modeling: Advanced simulation and modeling tools allow for virtual testing and optimization of casting parameters to minimize shrinkage defects. By simulating the solidification process and analyzing the effects of different parameters, engineers can make informed decisions to optimize the casting process and reduce shrinkage.

Optimizing the casting process for shrinkage reduction requires a comprehensive understanding of the influence of various parameters and their interactions. It involves a combination of empirical knowledge, experimentation, and advanced simulation techniques. By carefully controlling casting temperature, mold design, gating system, riser design, cooling rate, pouring time, material composition, and implementing robust process monitoring and control, foundries can significantly reduce shrinkage defects and produce high-quality castings.

Continual improvement efforts, process optimization, and ongoing collaboration between foundry operators,equipment manufacturers, and materials suppliers are essential in the pursuit of shrinkage reduction and process optimization. Through data-driven analysis, experimentation, and feedback loops, the casting process can be fine-tuned to minimize shrinkage and achieve consistent, high-quality castings.

Additionally, embracing advanced technologies such as digital twins, machine learning, and artificial intelligence can further enhance the optimization process. These tools can analyze vast amounts of data, identify patterns, and make predictive models to optimize casting parameters for shrinkage reduction. By leveraging these technologies, foundries can gain valuable insights into the complex interplay between casting parameters and shrinkage behavior.

It is important to note that optimizing casting parameters for shrinkage reduction is a continuous process. As new materials, alloys, and technologies emerge, foundries must adapt and refine their processes to stay at the forefront of shrinkage control. Collaboration with industry experts, research institutions, and equipment manufacturers can provide valuable insights and access to cutting-edge advancements in casting technology.

In conclusion, optimizing casting parameters for shrinkage reduction is a vital aspect of the casting process. By understanding the influence of casting temperature, mold design, gating system, riser design, cooling rate, pouring time, material composition, and implementing robust process monitoring and control, foundries can minimize shrinkage defects and enhance casting quality. Through ongoing research, innovation, and collaboration, the industry can continuously improve casting processes and achieve higher levels of shrinkage control, leading to cost savings, improved efficiency, and enhanced customer satisfaction.