The relentless pursuit of higher efficiency, power density, and reduced emissions in modern internal combustion engines places extreme demands on critical components. Among these, the cylinder liner operates in one of the most severe environments, subjected to intense mechanical loading, thermal cycles, and abrasive wear. The performance of this single component directly dictates the engine’s durability, fuel economy, and overall reliability. Traditionally, materials like pearlitic gray iron and alloyed cast irons have been employed. However, these often succumb to failures such as scuffing, cavitation erosion, and premature wear. This landscape has driven the exploration of superior materials, with austempered ductile iron (ADI) emerging as a prime candidate due to its exceptional combination of high strength, toughness, and wear resistance. Yet, the widespread adoption of ADI for cylinder liners faces significant hurdles: the inherent poor machinability of fully hardened ADI escalates manufacturing costs, and the conventional high-temperature austenitization process itself is energy-intensive.

This article delves into a strategic modification of the standard heat treatment for ductile iron casting, specifically targeting cylinder liner applications. By investigating a subcritical quenching process alongside the conventional isothermal quenching, we aim to engineer a microstructure that delivers an optimal balance of in-service performance and enhanced manufacturability. The core hypothesis is that carefully retaining certain phases from the as-cast structure can dramatically improve machinability while preserving, or even favorably altering, key functional properties like friction and thermal behavior.

1. Material and Methodological Foundation

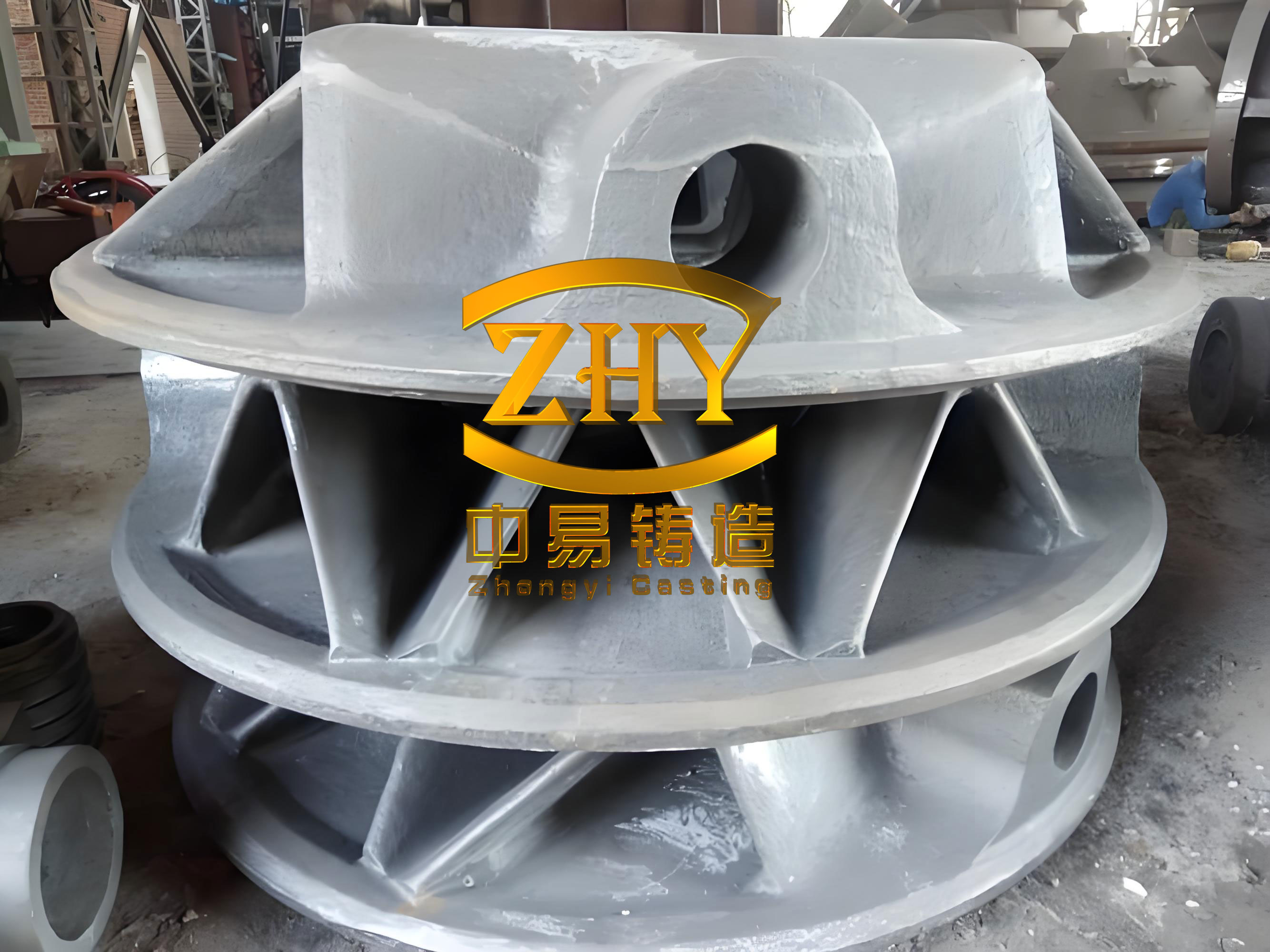

The base material for this investigation was a copper and niobium-alloyed ductile iron casting. The cylindrical liners were produced using a centrifugal casting process against a water-cooled metal mold, ensuring a fine, uniform microstructure with a high nodule count. The chemical composition of the alloy is detailed in Table 1, highlighting the deliberate additions of copper for solid solution strengthening and austenite stability, and niobium for carbide formation and grain refinement.

The as-cast microstructure served as the baseline. It consisted of a matrix of approximately 85% pearlite and 15% ferrite, with well-dispersed graphite nodules (spheroidality ≥90%, nodule size rating 7). Discrete particles of copper-rich phases and niobium carbides were also present, yielding a hardness ≥240 HB. This cast structure was then subjected to two distinct thermal processing routes, as defined in Table 2.

| C | Si | Cu | Nb | B | Mn | S | P | Mg | Ce | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 3.0-3.9 | 2.4-3.0 | 2.0-2.5 | 0.06-0.10 | 0.01-0.03 | <0.4 | <0.02 | <0.1 | 0.03-0.06 | 0.02-0.04 | Bal. |

| Process Parameter | Process 1: Subcritical Quenching | Process 2: Conventional Isothermal Quenching |

|---|---|---|

| Austenitization | 810 °C for 25 min | 920 °C for 25 min |

| Isothermal Quenching (Austempering) | 335 °C for 80 min | 335 °C for 80 min |

The fundamental difference lies in the austenitization temperature. Process 1 (Subcritical Quenching) was conducted at 810°C, a temperature within the α + γ + Graphite three-phase region of the Fe-C-Si-Cu phase diagram. Consequently, not all the initial ferrite dissolves. Process 2 (Conventional Isothermal Quenching) used 920°C, placing the material firmly in the γ + Graphite two-phase region, leading to a fully austenitic matrix prior to quenching. Both processes employed a molten salt bath for rapid transfer to an isothermal holding bath at 335°C to facilitate the austempering reaction.

2. The Architectural Evolution: Resultant Microstructures

The choice of austenitization temperature orchestrates a profound divergence in the final microstructural architecture of the ductile iron casting.

After Process 2 (920°C), the microstructure is characteristic of classic ADI. It comprises a matrix of acicular lower bainite, interlaced with a significant volume of carbon-enriched, copper-stabilized retained austenite. Fine, dispersed particles of niobium-rich carbides are also present. The complete dissolution of the initial ferrite results in a high-hardness matrix, with measured values ≥350 HB. This can be conceptually represented by the microstructural constituency:

$$ M_{Process2} = B_l + \gamma_{Cu}^{high-C} + (Nb,C)_x $$

where $B_l$ is lower bainite, $\gamma_{Cu}^{high-C}$ is copper-rich, high-carbon retained austenite, and $(Nb,C)_x$ represents niobium carbides.

Process 1 (810°C), the subcritical route, yields a distinctly hybrid microstructure. The key feature is the intentional retention of blocky and “bull’s eye” ferrite from the as-cast state. The final structure is therefore a composite: lower bainite, copper-rich retained austenite, blocky ferrite ($\alpha$), and minor niobium carbides. The retained ferrite acts as a soft phase, reducing the overall hardness to ≥300 HB. Its microstructure is described as:

$$ M_{Process1} = B_l + \gamma_{Cu}^{high-C} + \alpha + (Nb,C)_x $$

The presence of $\alpha$ is the defining variable between the two processes. The solubility of copper in austenite is significantly higher (~3.5%) than in ferrite at room temperature (~0.3%). Therefore, during both processes, the austenite phase becomes supersaturated with copper, a condition with critical implications for subsequent performance.

3. A Comparative Analysis of Mechanical and Physical Properties

The microstructural differences manifest directly in the macroscopic properties of the ductile iron casting. Table 3 summarizes the key mechanical properties.

| Property | Process 1 (Subcritical) | Process 2 (Conventional) |

|---|---|---|

| Tensile Strength, Rm (MPa) | 900 | 1050 |

| Hardness, HB | ≥300 | ≥350 |

| Elastic Modulus, E (GPa) | 170 | 175 |

| Elongation after Fracture, A (%) | 8 | 6 |

The data clearly shows the strength-hardness-ductility trade-off governed by the retained ferrite. Process 2, with its fully bainitic-austenitic matrix, delivers higher tensile strength and hardness. Process 1 sacrifices some strength and hardness but gains approximately 33% higher elongation. The elastic modulus, a structure-insensitive property largely dependent on the graphite morphology and overall alloy composition, remains essentially unchanged. This relationship can be framed as:

$$ R_m, HB \propto \frac{1}{V_\alpha} $$

$$ A \propto V_\alpha $$

where $V_\alpha$ is the volume fraction of soft, retained ferrite.

3.1 Thermal Properties: The Dominance of Graphite

An intriguing finding is the behavior of thermal properties. The coefficient of linear expansion and thermal conductivity were measured across a temperature range. The results, summarized for conductivity in Table 4 and shown graphically for expansion, reveal a pivotal insight.

| Process | 50°C | 100°C | 150°C | 200°C | 250°C | 300°C | 350°C | 400°C |

|---|---|---|---|---|---|---|---|---|

| Process 1 | 17.27 | 18.31 | 18.11 | 19.06 | 19.74 | 20.36 | 21.26 | 22.89 |

| Process 2 | 16.49 | 17.43 | 17.34 | 18.60 | 19.02 | 20.27 | 21.22 | 22.95 |

Both the linear expansion coefficient and thermal conductivity were nearly identical for the two microstructures at equivalent temperatures. This indicates that these properties in this ductile iron casting are primarily governed by the morphology, size, and distribution of the graphite nodules—which are unchanged by heat treatment—rather than by the metallic matrix structure (bainite vs. bainite+ferrite). This is a significant advantage, as it allows for matrix modification to improve machinability without adversely affecting the thermal interaction of the liner with the piston and engine block. Notably, the thermal conductivity of this alloyed ADI material is substantially lower than that of typical gray cast iron (often 41.5-52.5 W/(m·K)), a factor that must be accounted for in engine thermal management design. The convergence of conductivity values above 400°C for both processes is likely related to the precipitation of nano-sized copper-rich phases from the supersaturated austenite/bainite, altering the phonon scattering mechanisms within the matrix.

4. Tribological and Manufacturing Performance

4.1 Friction and Wear Behavior

The friction coefficient under lubricated conditions against a chrome-plated piston ring was evaluated at constant load (100 N) and varying speeds. The results, presented in Table 5, reveal nuanced tribological benefits from the subcritical process.

| Rotational Speed (rpm) | 25 | 50 | 75 | 100 | 150 | 250 | 375 |

|---|---|---|---|---|---|---|---|

| Process 1 (Subcritical) | 0.1277 | 0.1252 | 0.1240 | 0.1233 | 0.1219 | 0.1206 | 0.1196 |

| Process 2 (Conventional) | 0.1332 | 0.1292 | 0.1262 | 0.1241 | 0.1224 | 0.1212 | 0.1204 |

For both materials, the friction coefficient ($\mu$) decreased with increasing speed ($v$), following a trend typical for hydrodynamic or mixed lubrication regimes: $$ \mu \approx a – b \cdot \ln(v) $$ where $a$ and $b$ are material- and system-dependent constants. However, at every tested speed, the subcritically quenched (Process 1) ductile iron casting exhibited a lower friction coefficient than its conventional counterpart. The difference was most pronounced at lower speeds, where boundary lubrication effects are more significant. This superior frictional performance is attributed to the synergistic effect of the retained ferrite and the copper-rich phases. The softer ferrite may allow for smoother run-in and embeddability of wear debris, while the copper-rich phases, both initially present and potentially dynamically precipitated during frictional heating, act as solid lubricants and anti-galling agents at the asperity contact points.

4.2 A Breakthrough in Machinability

The most dramatic practical improvement was observed in machining performance. Using identical CNC machining centers, tooling (CBN inserts), and cutting parameters, a direct productivity test was conducted. The metric was the number of cylinder liners that could be finished before tool wear necessitated replacement.

The result was unequivocal: the subcritically quenched ductile iron casting from Process 1 allowed for the machining of over five times as many components as the conventionally austempered ductile iron casting from Process 2 under the same conditions. This extraordinary improvement stems from multiple factors. The lower bulk hardness (≥300 HB vs. ≥350 HB) directly reduces cutting forces and tool stress. More importantly, the presence of the soft ferrite phases and the copper-rich particles modifies the chip formation mechanism, promoting shorter, more brittle chips that break away cleanly, thereby reducing tool-chip interface heat and adhesion. This translates directly to lower machining costs, higher production rates, and longer tool life, effectively removing a major barrier to the adoption of high-performance ductile iron casting for complex components like cylinder liners.

5. Discussion: The Integrated Performance Paradigm

This investigation moves beyond a simple comparison of two heat treatments; it demonstrates a philosophy of microstructural design for ductile iron casting. The goal is not to maximize any single property but to optimize the entire suite of properties for a specific application—in this case, an engine cylinder liner.

The conventional isothermal quenching (Process 2) produces a material optimized for peak strength and wear resistance. Its fully bainitic-austenitic matrix is ideal for highly loaded applications. However, its poor machinability and higher processing temperature (920°C vs. 810°C) are significant economic and manufacturing liabilities.

The subcritical quenching process (Process 1) introduces a calculated compromise. By retaining a controlled amount of ferrite, it deliberately lowers strength and hardness. However, this “loss” is strategically leveraged to gain substantial benefits:

- Dramatically Enhanced Machinability: The 5x improvement in tool life is a transformative economic advantage.

- Improved Frictional Behavior: The lower and more stable friction coefficient can contribute to reduced parasitic losses and potentially better fuel efficiency in an engine.

- Retained Ductility: The increased elongation provides a margin of safety against brittle fracture under complex stress states.

- Preserved Thermal Properties: Critical for engine function, the thermal expansion and conductivity are unchanged.

- Energy Efficiency: The lower austenitizing temperature (810°C) reduces energy consumption during heat treatment.

The performance matrix can be conceptualized. For a property index $P_i$, where $i$ denotes strength, machinability, friction, etc., the subcritical process re-weights these indices favorably for the cylinder liner application:

$$ \text{Overall Fitness}_{Liner} = w_S \cdot P_S + w_M \cdot P_M + w_F \cdot P_F + w_T \cdot P_T + w_E \cdot P_E $$

where $w$ are weighting factors. For a liner, the weights for machinability ($w_M$), friction ($w_F$), and energy ($w_E$) are high relative to the weight for ultimate strength ($w_S$). Process 1 increases $P_M$, $P_F$, and $P_E$ while causing an acceptable decrease in $P_S$, thereby maximizing the Overall Fitness.

6. Concluding Synthesis

This detailed examination unequivocally shows that the thermal processing route is a powerful conductor, orchestrating the microstructural symphony of a ductile iron casting. The subcritical quenching process, conducted in the intercritical (α+γ+G) region, successfully engineers a hybrid microstructure comprising lower bainite, copper-stabilized retained austenite, and intentionally retained blocky ferrite. This structure results in a material with a balanced and application-tailored profile:

- It possesses sufficient strength (≥900 MPa) and high wear resistance inherent to the bainitic-austenitic matrix.

- It exhibits superior machinability, reducing production costs by a factor of five or more.

- It demonstrates favorable tribological properties with a lower friction coefficient under engine-like conditions.

- It maintains the critical thermal properties dictated by the graphite phase.

- It achieves this with a lower-energy input during heat treatment.

Therefore, for components like cylinder liners where the property requirements are multifaceted—encompassing not just service performance but also manufacturability and production economy—the subcritical quenching of alloyed ductile iron casting presents a technologically and commercially superior solution. This approach exemplifies the modern paradigm in materials engineering: intelligent microstructural design to create the right material for the job, rather than simply applying the strongest material available. It paves the way for the broader utilization of high-performance ductile iron casting in demanding automotive and engineering applications.