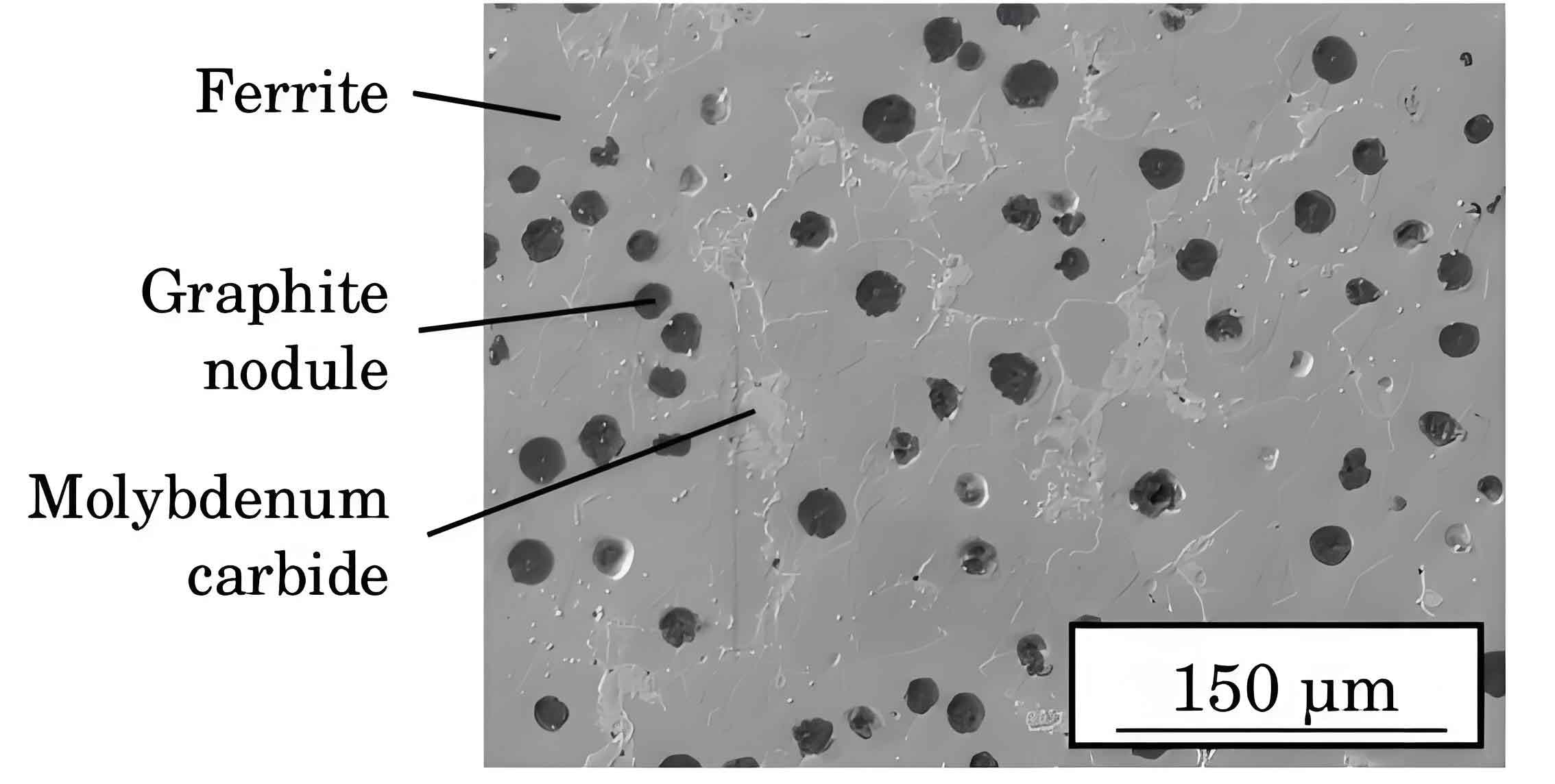

Spheroidal Graphite Cast Iron is renowned for its superior mechanical properties, including high strength, ductility, and toughness. These properties are primarily due to the presence of spherical graphite nodules within a ferritic or pearlitic matrix. The addition of various alloying elements can further enhance the mechanical, physical, and chemical properties of Spheroidal Graphite Cast Iron, making it suitable for a broader range of applications. This article explores the role of alloying elements in enhancing the properties of Spheroidal Graphite Cast Iron, focusing on their effects and the benefits they bring to the material.

Key Alloying Elements in Spheroidal Graphite Cast Iron

The primary elements used in alloying Spheroidal Graphite Cast Iron include magnesium, silicon, manganese, nickel, copper, chromium, and molybdenum. Each of these elements contributes to different aspects of the iron’s properties.

1. Magnesium (Mg)

Magnesium is a crucial element in the production of Spheroidal Graphite Cast Iron. It promotes the formation of spherical graphite nodules, which are essential for the enhanced mechanical properties of the material.

Effects of Magnesium

- Nodulizing Agent: Converts graphite flakes into spherical nodules, reducing stress concentrations and improving ductility.

- Improves Toughness: Enhances the toughness and impact resistance of the iron.

List 1: Benefits of Magnesium

- Promotes formation of spherical graphite nodules.

- Improves toughness and impact resistance.

2. Silicon (Si)

Silicon is added to Spheroidal Graphite Cast Iron to stabilize the graphite and influence the matrix structure. It is also an essential deoxidizer during the melting process.

Effects of Silicon

- Graphite Stabilization: Promotes the formation and stability of graphite nodules.

- Matrix Influence: Encourages the formation of a ferritic matrix, which enhances ductility.

- Oxidation Resistance: Improves oxidation resistance at high temperatures.

Table 1: Effects of Silicon

| Effect | Description |

|---|---|

| Graphite Stabilization | Promotes formation and stability of graphite nodules |

| Matrix Influence | Encourages formation of a ferritic matrix |

| Oxidation Resistance | Improves resistance to oxidation at high temperatures |

3. Manganese (Mn)

Manganese is an essential alloying element that influences the hardness and strength of Spheroidal Graphite Cast Iron by affecting the matrix structure.

Effects of Manganese

- Matrix Strengthening: Increases hardness and tensile strength by promoting a pearlitic matrix.

- Carbide Formation: Helps control carbide formation, improving wear resistance.

List 2: Benefits of Manganese

- Increases hardness and tensile strength.

- Improves wear resistance through carbide formation.

4. Nickel (Ni)

Nickel is known for its ability to enhance toughness and corrosion resistance. It also stabilizes the austenitic structure at high temperatures.

Effects of Nickel

- Toughness Improvement: Enhances the toughness and ductility of the iron.

- Corrosion Resistance: Improves resistance to corrosive environments.

- High-Temperature Stability: Stabilizes the austenitic phase, enhancing performance at elevated temperatures.

Table 2: Effects of Nickel

| Effect | Description |

|---|---|

| Toughness Improvement | Enhances toughness and ductility |

| Corrosion Resistance | Improves resistance to corrosive environments |

| High-Temperature Stability | Stabilizes the austenitic phase for better high-temperature performance |

5. Copper (Cu)

Copper is added to Spheroidal Graphite Cast Iron to enhance its strength and resistance to oxidation. It is particularly effective in improving the mechanical properties without significantly affecting ductility.

Effects of Copper

- Strength Enhancement: Increases tensile and yield strength.

- Oxidation Resistance: Enhances resistance to oxidation, especially at high temperatures.

List 3: Benefits of Copper

- Increases tensile and yield strength.

- Improves oxidation resistance at high temperatures.

6. Chromium (Cr)

Chromium is an alloying element that significantly enhances the wear resistance and corrosion resistance of Spheroidal Graphite Cast Iron. It also contributes to the formation of carbides, which harden the matrix.

Effects of Chromium

- Wear Resistance: Improves wear resistance by forming hard carbides.

- Corrosion Resistance: Enhances resistance to corrosive environments, particularly in acidic conditions.

Table 3: Effects of Chromium

| Effect | Description |

|---|---|

| Wear Resistance | Improves wear resistance through carbide formation |

| Corrosion Resistance | Enhances resistance to corrosive environments |

7. Molybdenum (Mo)

Molybdenum is added to Spheroidal Graphite Cast Iron to enhance its high-temperature strength and creep resistance. It also improves hardenability and toughness.

Effects of Molybdenum

- High-Temperature Strength: Increases strength at elevated temperatures.

- Creep Resistance: Enhances resistance to deformation under prolonged stress.

- Toughness Improvement: Improves overall toughness and hardenability.

List 4: Benefits of Molybdenum

- Increases high-temperature strength.

- Enhances creep resistance.

- Improves toughness and hardenability.

Combined Effects of Alloying Elements

The combination of various alloying elements can synergistically enhance the properties of Spheroidal Graphite Cast Iron. The careful selection and balance of these elements allow for tailored properties to meet specific application requirements.

Table 4: Combined Effects of Alloying Elements

| Alloying Combination | Synergistic Effects |

|---|---|

| Nickel and Copper | Enhanced toughness and strength, improved oxidation resistance |

| Silicon and Chromium | Improved oxidation and corrosion resistance |

| Manganese and Molybdenum | Increased hardness, strength, and high-temperature performance |

Heat Treatment and Alloying Elements

The effectiveness of alloying elements in Spheroidal Graphite Cast Iron can be further enhanced through appropriate heat treatment processes. Heat treatment modifies the microstructure, optimizing the distribution and effects of the alloying elements.

Key Heat Treatment Processes

- Annealing: Enhances ductility and reduces internal stresses, improving toughness.

- Normalizing: Refines grain structure, increases strength and toughness.

- Austempering: Produces a bainitic structure, significantly improving strength and wear resistance.

- Quenching and Tempering: Increases hardness and strength while maintaining toughness.

Table 5: Heat Treatment and Alloying Effects

| Heat Treatment Process | Combined Effects with Alloying Elements |

|---|---|

| Annealing | Enhances ductility and toughness (Si, Ni, Mo) |

| Normalizing | Increases strength and toughness (Mn, Cr) |

| Austempering | Improves wear resistance and strength (Ni, Cu, Mo) |

| Quenching and Tempering | Increases hardness and strength, maintains toughness (Cr, Mo) |

Applications Enhanced by Alloying Elements

The enhanced properties of Spheroidal Graphite Cast Iron through alloying elements make it suitable for various demanding applications across different industries.

Automotive Industry

- Engine Components: Crankshafts, camshafts, and cylinder heads benefit from enhanced strength and wear resistance.

- Suspension Parts: Control arms and suspension knuckles utilize improved toughness and impact resistance.

Aerospace Industry

- Landing Gear: Components benefit from high strength and toughness at elevated temperatures.

- Engine Parts: Turbine housings and other high-temperature components use improved oxidation and creep resistance.

Industrial Machinery

- Pumps and Valves: Enhanced corrosion and wear resistance improve longevity in harsh environments.

- Heavy Machinery: Gears, bearings, and other parts utilize increased strength and toughness for demanding applications.

Table 6: Applications of Enhanced Spheroidal Graphite Cast Iron

| Industry | Applications |

|---|---|

| Automotive | Engine components, suspension parts |

| Aerospace | Landing gear, engine parts |

| Industrial Machinery | Pumps, valves, heavy machinery |

Conclusion

Alloying elements play a crucial role in enhancing the properties of Spheroidal Graphite Cast Iron, making it a versatile and high-performance material for various applications. By carefully selecting and balancing elements such as magnesium, silicon, manganese, nickel, copper, chromium, and molybdenum, and combining them with appropriate heat treatment processes, the mechanical, physical, and chemical properties of Spheroidal Graphite Cast Iron can be significantly improved. These enhancements allow for the production of components that meet the stringent demands of industries such as automotive, aerospace, and industrial machinery, ensuring durability, reliability, and performance. As research and development continue to advance, the potential for further improvements in the properties and applications of Spheroidal Graphite Cast Iron remains substantial.