The automotive industry is undergoing a transformative shift with the rise of electric vehicles (EVs), driven by the need for sustainable transportation and stringent emissions regulations. Spheroidal graphite cast iron (SG iron), also known as ductile iron, has emerged as a critical material in EV manufacturing due to its exceptional mechanical properties, versatility, and cost-effectiveness. This article explores the role of spheroidal graphite cast iron in electric vehicle manufacturing, detailing its benefits, applications, and future prospects. Comprehensive tables and lists are included to enhance understanding.

Introduction

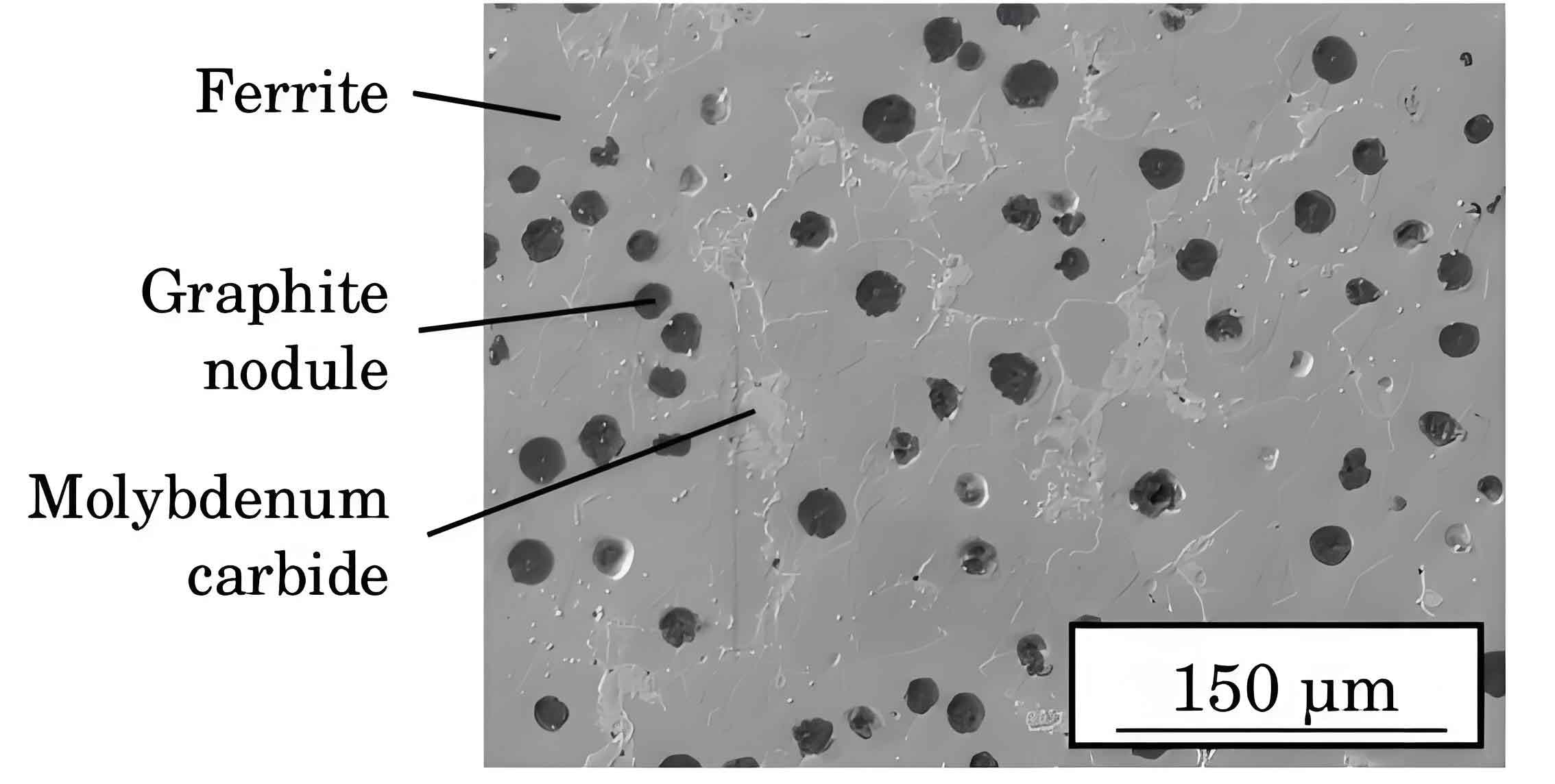

Spheroidal graphite cast iron, characterized by its graphite nodules within the iron matrix, offers superior strength, ductility, and resistance to wear and fatigue compared to traditional cast iron. These properties make spheroidal graphite cast iron particularly suitable for various components in electric vehicles, which demand high performance and reliability. As the automotive industry continues to evolve, the use of spheroidal graphite cast iron is expected to grow, contributing to more efficient and durable electric vehicles.

Benefits of Spheroidal Graphite Cast Iron

- High Strength and Ductility:

- Spheroidal graphite cast iron combines high tensile strength with excellent ductility, enabling the production of lightweight yet robust components.

- Excellent Wear Resistance:

- The material’s wear resistance ensures the longevity of critical components subjected to repetitive stress and friction.

- Good Fatigue Resistance:

- Spheroidal graphite cast iron can withstand cyclic loading, which is essential for components in dynamic systems.

- Cost-Effectiveness:

- Compared to other high-performance materials, spheroidal graphite cast iron is relatively inexpensive, offering a cost-effective solution without compromising quality.

- Versatility in Manufacturing:

- Spheroidal graphite cast iron can be easily cast into complex shapes, allowing for greater design flexibility in component manufacturing.

Table: Benefits of Spheroidal Graphite Cast Iron

| Benefit | Description | Impact on EV Manufacturing |

|---|---|---|

| High Strength and Ductility | Combines high tensile strength with excellent ductility | Lightweight, robust components |

| Excellent Wear Resistance | Ensures longevity under stress and friction | Increased component lifespan |

| Good Fatigue Resistance | Withstands cyclic loading | Reliable performance in dynamic systems |

| Cost-Effectiveness | Relatively inexpensive compared to other high-performance materials | Affordable high-quality components |

| Versatility in Manufacturing | Easily cast into complex shapes | Greater design flexibility |

Applications of Spheroidal Graphite Cast Iron in Electric Vehicles

- Motor Housings:

- Components: Enclosures for electric motors.

- Benefits: Provides structural integrity and protection for internal components.

- Suspension Systems:

- Components: Control arms, steering knuckles, and other suspension parts.

- Benefits: Enhances durability and performance of the vehicle’s suspension system.

- Brake Components:

- Components: Brake discs, calipers, and brackets.

- Benefits: Offers high wear resistance and reliability in braking systems.

- Battery Housings:

- Components: Casings and supports for EV batteries.

- Benefits: Ensures the safety and stability of the battery pack.

- Gearbox and Transmission Parts:

- Components: Gears, shafts, and casings.

- Benefits: Provides strength and wear resistance for efficient power transmission.

List: Key Applications of Spheroidal Graphite Cast Iron in Electric Vehicles

- Motor Housings:

- Enclosures for electric motors

- Structural integrity and protection

- Suspension Systems:

- Control arms

- Steering knuckles

- Enhanced durability and performance

- Brake Components:

- Brake discs

- Calipers

- Brackets

- High wear resistance and reliability

- Battery Housings:

- Casings and supports for EV batteries

- Safety and stability of the battery pack

- Gearbox and Transmission Parts:

- Gears

- Shafts

- Casings

- Strength and wear resistance for power transmission

Current Trends in Using Spheroidal Graphite Cast Iron in EV Manufacturing

- Lightweighting Initiatives:

- Reducing vehicle weight to improve energy efficiency and extend driving range.

- Advanced Casting Techniques:

- Utilizing precision casting and computer-aided design (CAD) to create complex, high-performance components.

- Integration with Composite Materials:

- Combining spheroidal graphite cast iron with lightweight composites to enhance overall vehicle performance.

- Sustainability Focus:

- Employing eco-friendly production methods and recycling practices to minimize environmental impact.

- Customization and Modular Design:

- Developing modular components that can be easily customized for different EV models.

Table: Current Trends in Using Spheroidal Graphite Cast Iron in EV Manufacturing

| Trend | Description | Expected Benefits |

|---|---|---|

| Lightweighting Initiatives | Reducing vehicle weight | Improved energy efficiency, extended driving range |

| Advanced Casting Techniques | Precision casting and CAD | Creation of complex, high-performance components |

| Integration with Composites | Combining spheroidal graphite cast iron with lightweight composites | Enhanced overall vehicle performance |

| Sustainability Focus | Eco-friendly production methods and recycling | Minimized environmental impact |

| Customization and Modular Design | Developing modular components | Easier customization for different EV models |

Future Prospects for Spheroidal Graphite Cast iron in EV Manufacturing

- Enhanced Material Properties:

- Ongoing research to develop spheroidal graphite cast iron with even higher strength and ductility.

- Smart Manufacturing:

- Incorporation of Industry 4.0 technologies, such as IoT and AI, for optimized production processes.

- Increased Adoption in New Markets:

- Expanding the use of spheroidal graphite cast iron in emerging EV markets worldwide.

- Collaborative Innovation:

- Partnerships between automotive manufacturers and material scientists to drive innovation.

- Regulatory Support:

- Supportive regulations promoting the use of sustainable and high-performance materials in EV manufacturing.

List: Future Prospects for Spheroidal Graphite Cast Iron in EV Manufacturing

- Enhanced Material Properties:

- Higher strength and ductility

- Smart Manufacturing:

- Industry 4.0 technologies (IoT, AI)

- Optimized production processes

- Increased Adoption in New Markets:

- Expanding use in emerging EV markets

- Collaborative Innovation:

- Partnerships between manufacturers and scientists

- Driving innovation

- Regulatory Support:

- Supportive regulations

- Promotion of sustainable and high-performance materials

Conclusion

Spheroidal graphite cast iron plays a pivotal role in the manufacturing of electric vehicles, offering a unique combination of strength, ductility, wear resistance, and cost-effectiveness. Its applications in motor housings, suspension systems, brake components, battery housings, and gearbox parts underscore its versatility and importance in producing durable and efficient electric vehicles. As the industry embraces trends like lightweighting, advanced casting techniques, and sustainability, spheroidal graphite cast iron is set to remain a cornerstone of EV manufacturing. Looking ahead, ongoing innovations and supportive regulations will further enhance its adoption and performance, ensuring that spheroidal graphite cast iron continues to contribute to the advancement of electric vehicle technology.