1. Introduction

Lost foam casting is a green casting process with near-net shape and precise forming characteristics. The magnetic separator is a crucial device in the sand treatment production line of lost foam casting, which is closely related to the production cost. This article focuses on the transformation of the magnetic separator to improve its performance and efficiency.

2. The Process Flow of Lost Foam Casting

The production process of the 10,000 t/a lost foam casting production line in the company is as follows: After pouring, the casting in the sand box is automatically turned over under the control of the system PLC program. The casting and sand are separated by the vibrating shakeout machine, and the large particles and impurities are screened by the vibrating conveyor screen. The used sand is transported to the magnetic separator by the 1st-stage elevator for magnetic separation of iron beans to achieve iron-sand separation. The separated iron enters the storage hopper and is then returned to the furnace. The used sand is cooled by the boiling cooling bed, and then transported vertically to the intermediate sand bin and sand temperature regulating bin by the 2nd and 3rd-stage elevators. After being cooled again by the sand temperature regulator under the sand temperature regulating bin, it is transported vertically to the molding sand bin by the 4th-stage elevator for reuse, realizing the automatic recycling and reuse of the used sand. The dust is collected and treated by the dust collector.

3. The Structure and Working Principle of the Magnetic Separator

The magnetic separator is mainly composed of a transmission device, a magnetic drum, an adjustment handle, a sorting chamber, an inlet plate, a feed chute, an iron discharge chute, a sand discharge chute, and a dust removal part. During production, the materials are transported to the magnetic separator by the 1st-stage elevator, enter the sorting chamber through the feed chute, and are scattered by the inlet plate and fall onto the magnetic drum. The iron beans and iron filings are adsorbed on the drum by the magnetic force of the magnetic blocks in the drum, and the sand falls into the sand discharge chute under the action of gravity and enters the next process equipment. The iron adsorbed on the drum is carried to the non-magnetic field area and falls into the iron discharge chute under the action of gravity.

4. Existing Problems

After the installation and commissioning of the lost foam casting production line in the company, the following problems occurred in the magnetic separator:

- Poor iron-sand separation effect: A large amount of iron-sand mixture could not be separated in time, resulting in a high iron content in the used sand entering the boiling cooling bed, which affected the cooling effect and quality of the molding sand.

- High sand temperature: The high iron content in the used sand led to a high sand temperature, which exceeded the process requirements and caused deformation of the pattern cluster, affecting the quality of the casting products.

- Frequent production stoppages: The deposition of iron in the boiling cooling bed led to blockage, which required frequent production stoppages for cleaning and screening, reducing the production efficiency.

- Increased labor intensity: The iron-sand mixture removed from the boiling cooling bed needed to be manually screened for reuse, increasing the labor intensity of the workers.

- Equipment damage: The blockage in the boiling cooling bed caused by the deposition of iron, resulting in equipment failures such as leakage, bearing sand entry, shaft wear, and magnetic drum leakage, increasing the equipment maintenance cost.

5. Problem Analysis

The reasons for the above problems are as follows:

- High sand temperature: The temperature of the sand entering the magnetic separator is too high, which causes the magnetic attenuation of the magnetic blocks and affects the separation effect.

- Inappropriate structure: The such as the large gap between the drum and the inlet and outlet plates, the easy magnetization of the discharge chute, and the small valve opening lead to the backflow of sand and the increase of the sand discharge amount.

- Large screen mesh: The screen mesh with a large aperture allows some iron beans to “leak through”, resulting in incomplete separation.

6. Transformation Solutions

To solve the above problems, the following transformation measures are taken for the magnetic separator:

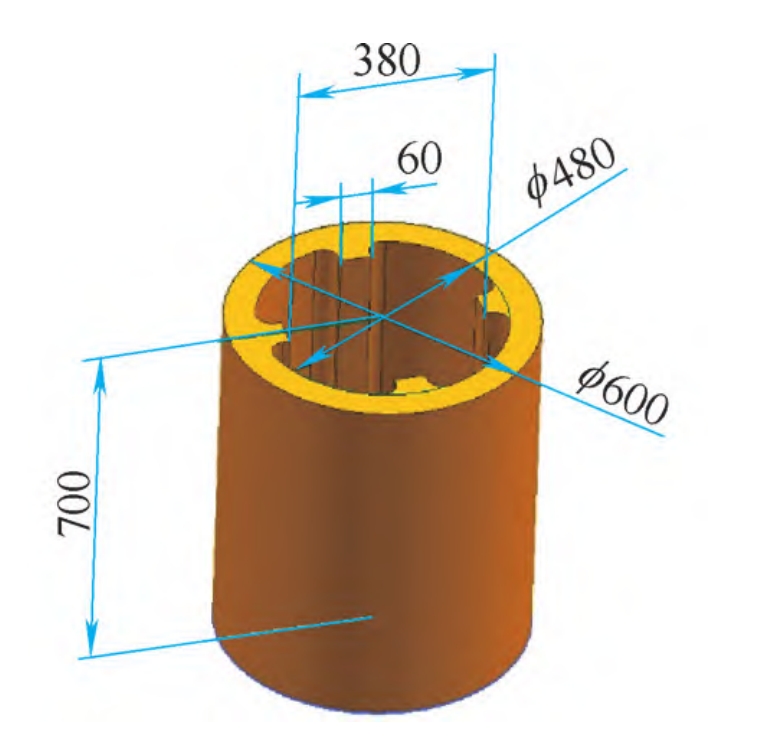

- Re-making the magnetic drum: The magnetic drum is re-made with a jumping roller system, and the roller skin material is changed from 3 mm to 4 mm stainless steel. The magnetic block is replaced with a neodymium iron boron material, and the working temperature and magnetic field strength are increased. The installation direction of the magnetic drum is also adjusted.

- Adjusting the inlet and outlet structures: The is extended to prevent the backflow of sand, and a baffle is added at the discharge port to improve the sorting effect. The discharge chute is re-made with stainless steel to ensure smooth material discharge.

- Adding inspection and adjustment devices: An inspection door is added to facilitate the inspection and adjustment of the sorting situation, and an adjustment plate is added to the inlet plate to ensure the uniformity of the material layer on the drum.

- Optimizing the dust removal system: The dust removal valve opening is adjusted to ensure a slight negative pressure in the sorting chamber, and the screen mesh is replaced with a smaller aperture to improve the screening effect.

7. Production Effects

After the transformation, the magnetic separator has achieved the following good results:

- Improved sorting efficiency: The sorting efficiency is greatly improved, and the iron content in the used sand is significantly reduced.

- Extended cleaning cycle: The cleaning cycle of the boiling cooling bed is extended to more than 5 months, reducing the number of production stoppages.

- Reduced production costs: The timely separation and recycling of iron reduce the production cost, and the reduced equipment failures also save maintenance costs.

- Improved product quality: The reduced iron content in the used sand improves the quality of the molding sand and casting products.

- Enhanced environmental protection: The transformation reduces dust emissions and promotes environmental protection.

8. Conclusion

The transformation of the magnetic separator in the lost foam casting production line has effectively solved the problems of poor iron-sand separation effect, high sand temperature, frequent production stoppages, and increased labor intensity. It has improved the sorting efficiency, reduced the production cost, improved the product quality, and enhanced the environmental protection. With the development of the casting industry and the promotion of intelligent manufacturing, the application of automatic production lines will become more and more widespread. The optimization and improvement of key equipment such as magnetic separators will play an important role in improving the production efficiency and quality of the casting industry.