It can be seen from the test that when the vibration frequency is 35Hz, the tensile strength of vibration lost foam casting nodular cast iron is higher and the elongation is better. Therefore, by means of thermal analysis, the thermodynamic characteristics of microstructure transformation of nodular cast iron in vibration lost foam casting and no vibration lost foam casting at 35Hz were studied.

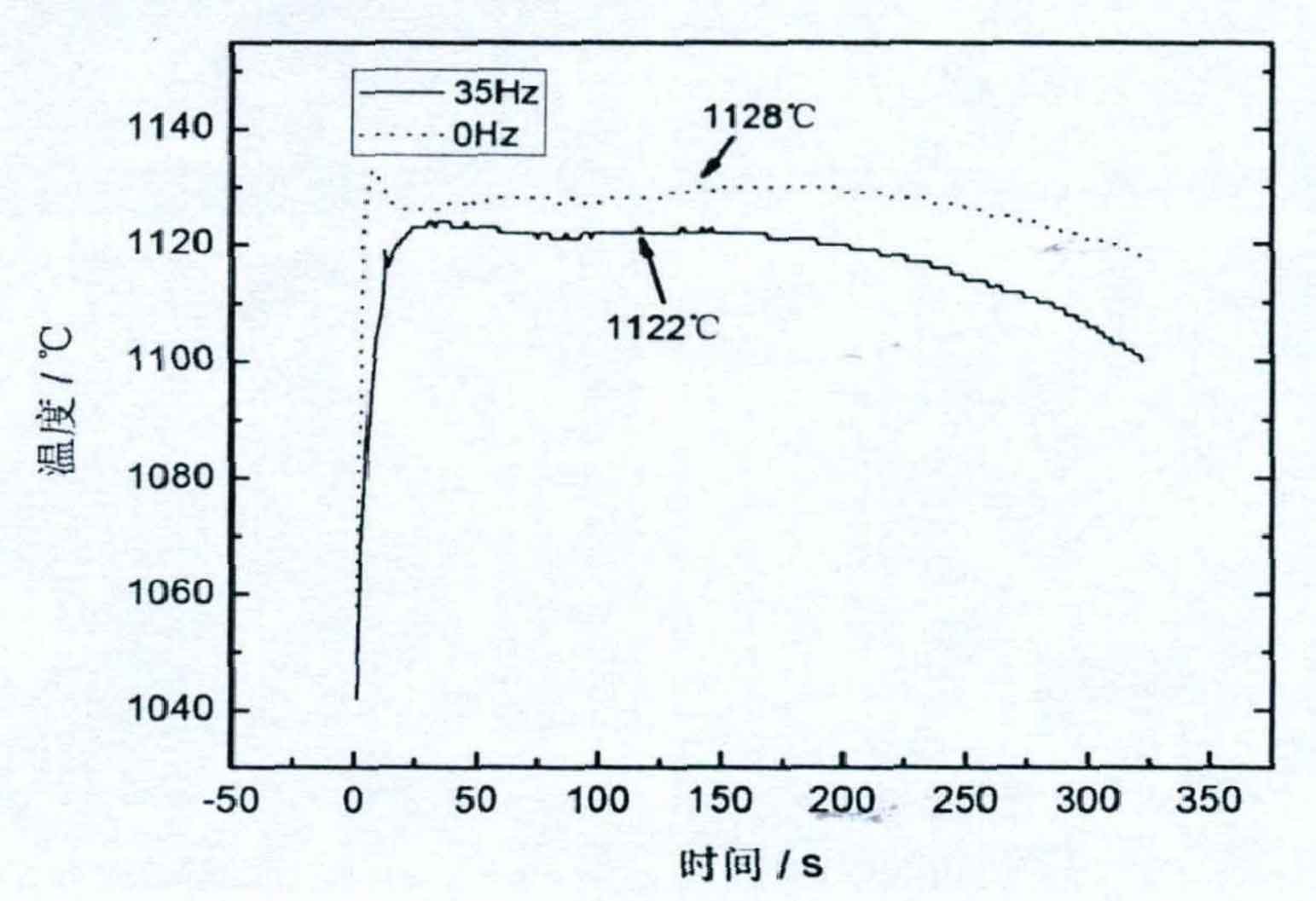

Fig. 1 is the cooling curve of the metal solution in the columnar crystal zone of nodular cast iron measured under the conditions of vibration (vibration frequency 35Hz) and no vibration.

It can be seen from the figure that the eutectic point temperature of vibration lost foam casting nodular cast iron is about 1122 ° C, which is nearly 32 ° C lower than the theoretical eutectic point (1154 ° C); However, the eutectic point temperature in the columnar region of lost foam casting ductile iron without vibration is about 1128 ° C, which is 26 ° C lower than the theoretical eutectic point (1154 ° C). Comparing the eutectic point temperature of the two processes, it can be seen that the eutectic point temperature of the vibration lost foam casting ductile iron is lower than that of the lost foam casting ductile iron without vibration. In addition, it can be seen from the figure that the eutectic transformation time of the vibration lost foam casting ductile iron is shorter. It can be seen that vibration reduces the eutectic transition temperature of nodular graphite cast iron in lost foam casting, that is, the eutectic transition of nodular graphite cast iron in lost foam casting is carried out at a lower temperature, which reduces the diffusion rate and time of atoms in the eutectic transition process. Therefore, vibration lost foam casting is beneficial to obtain smaller graphite balls.

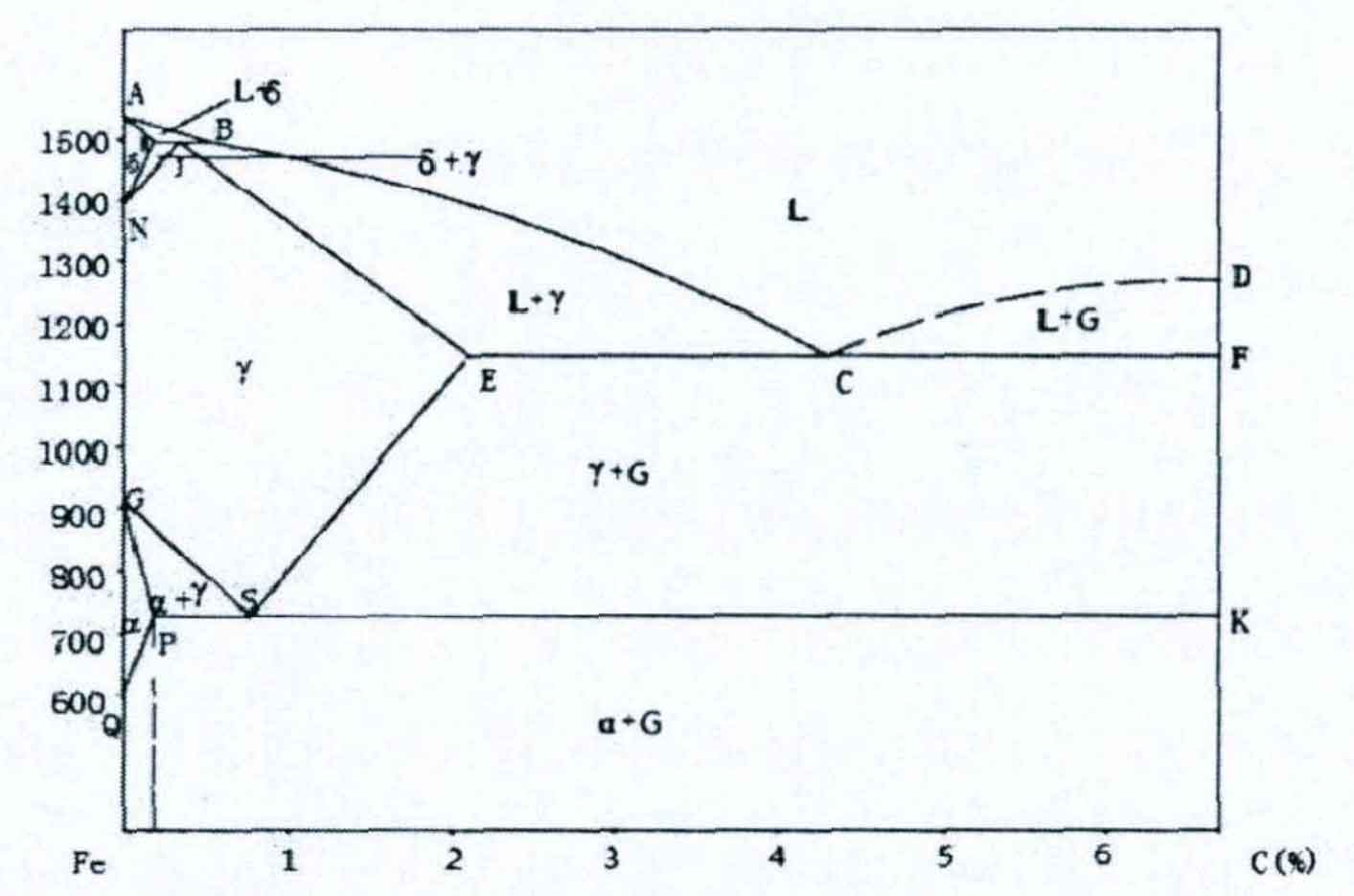

According to the iron carbon alloy phase diagram (as shown in Figure 2), the primary phase of nodular cast iron is graphite, and its formation process has gone through two stages, namely, the nucleation and growth of graphite balls.

When the metal solution with hypereutectic (or eutectic) composition is cooled to the liquidus and has a certain degree of undercooling, there will be precipitation of high-temperature materials in the metal solution. The precipitates, as the nucleation core of graphite, make the graphite heterogeneous

Core, graphite is precipitated from the metal body, and the carbon atoms in the metal body continuously diffuse to the surface of the graphite core, resulting in the continuous growth of the graphite core, and finally the formation of graphite balls.