Some manufacturers use high-strength titanium alloy to cast connecting rods, which are light in weight and insensitive to stress concentration. Titanium and titanium alloy is an important metal structural material rising in the 1950s. Compared with other metal structural materials, it has three significant advantages: high strength, good medium temperature performance and corrosion resistance. The corrosion resistance of titanium is better than that of stainless steel. Its density is 1/2 that of iron, and its toughness is also equivalent to that of steel.

It is widely used in the aviation industry. Since the mid-1980s, titanium alloy forgings have been widely used in aircraft engines, space test modules, space shuttles and missiles developed by developed countries in the world, such as the United States, Western Europe and Japan. It is one of the “three pillars of materials” juxtaposed with aluminum and composite materials. Its disadvantages are high cost, poor machinability, difficult cutting, welding and surface treatment. The strength, processability and corrosion resistance of titanium alloy can be improved. TC4 is the most widely used titanium alloy, accounting for about half of the existing titanium alloy. Since the 1990s, some manufacturers have also used titanium alloy TC4 to accurately forge automobile connecting rods. The connecting rod made of titanium alloy is the most effective to reduce the weight of the engine and greatly improve the performance.

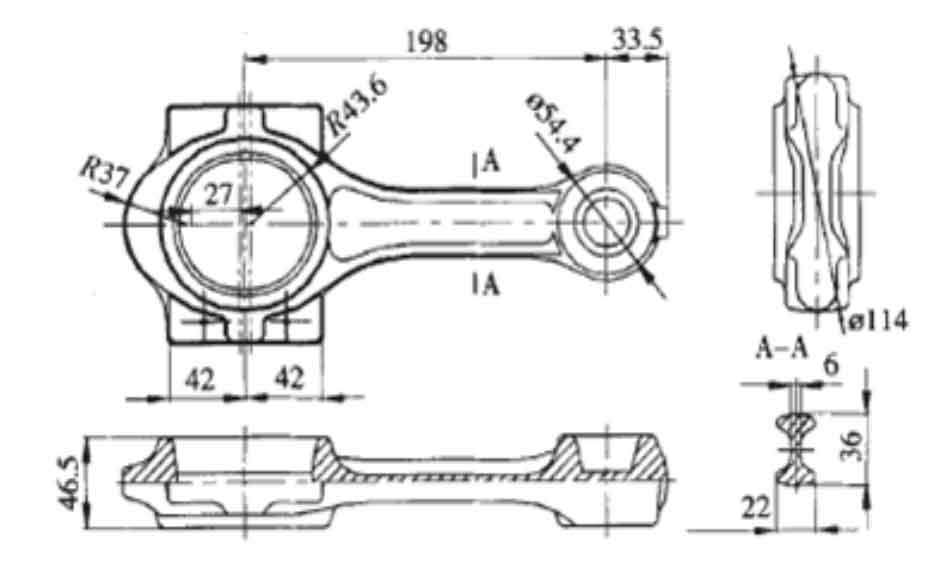

Example of using titanium alloy in automobile: titanium alloy connecting rod Ti-6A1-4V has been used in connecting rod of motorcycle and four-wheel electric vehicle, which is 15% ~ 20% lighter than steel connecting rod. The new Ferrari 3.5lv8 and Acura NSX engines in Italy use titanium alloy connecting rods for the first time. The greatest resistance to the application of Ti and titanium alloys comes from their high prices, so the development of alloys and production processes focus on reducing costs. Toyota developed low-cost titanium matrix composites. The composite is produced by powder metallurgy with Ti-6A1-4V alloy as matrix and TiB as reinforcement. The composite material has low cost and excellent performance, and has been applied in engine connecting rod. China’s titanium ore reserves rank first in the world, and the application of titanium has broad prospects.