1.Detect defects

The probe specified by the supplier and the buyer shall be used to scan the inspection area of steel castings. The position where any of the following conditions occurs shall be marked:

(1) The position where the defect echo amplitude is equal to or greater than the distance amplitude curve;

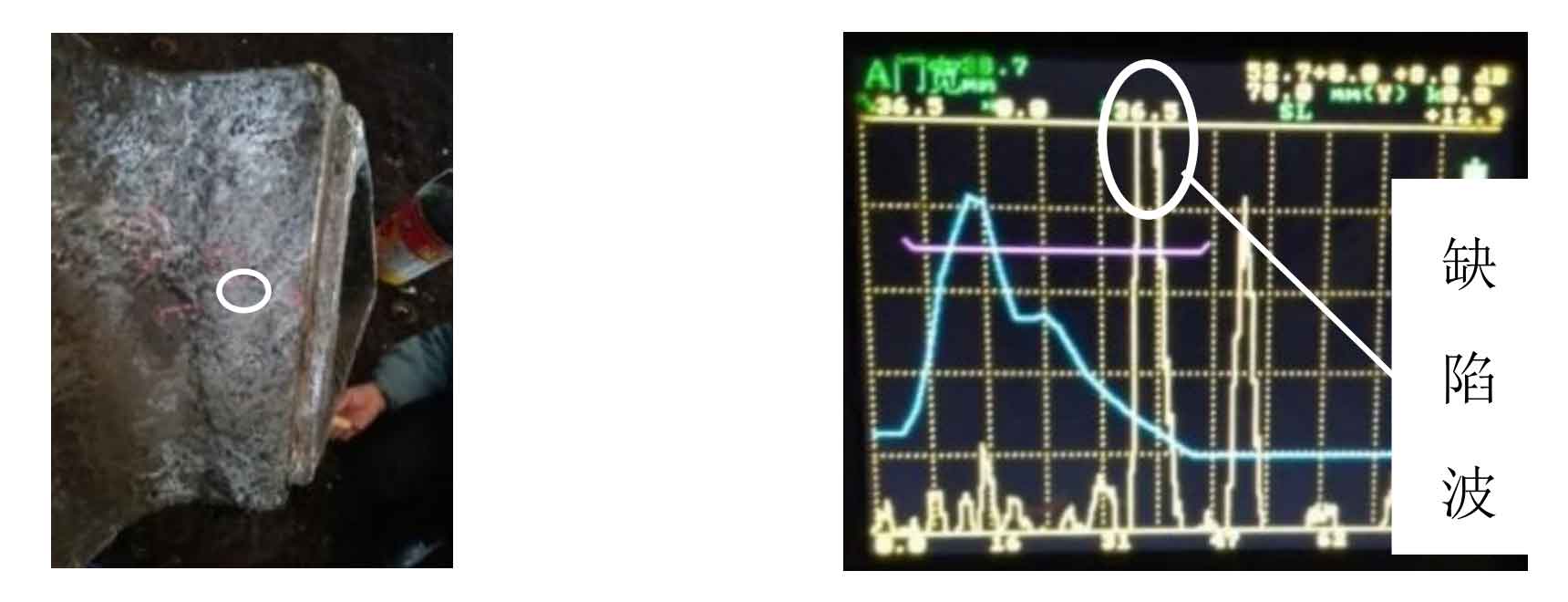

(2) The position where the bottom echo amplitude decreases by 12dB or more;

(3) No matter the echo amplitude of the defect, the position where the linear and flake characteristic defects appear.

2.Calculate defect equivalent

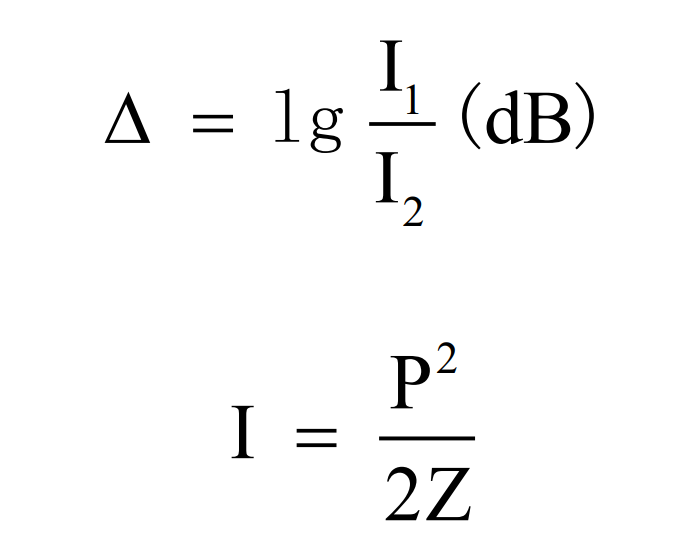

Initial sensitivity in flaw detection Φ 3 、 Φ 6 equivalent. When calculating the defect equivalent, the concept of decibel value must be introduced first. As shown in the formula, we define the decibel value as the logarithm of the sound pressure ratio.

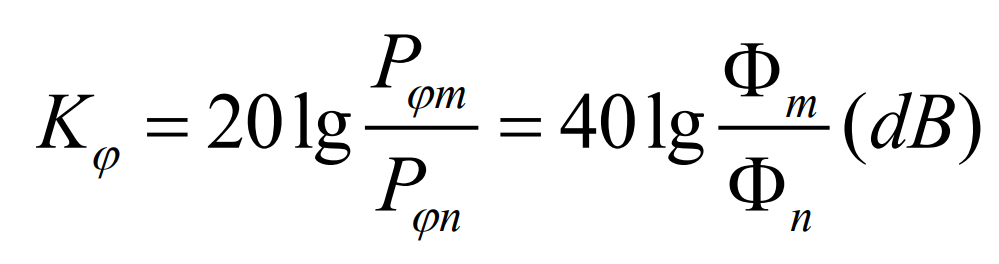

The DB value of the phase difference between flat bottom holes with different apertures in the same sound path can be obtained by introducing the formula, as shown in the formula.

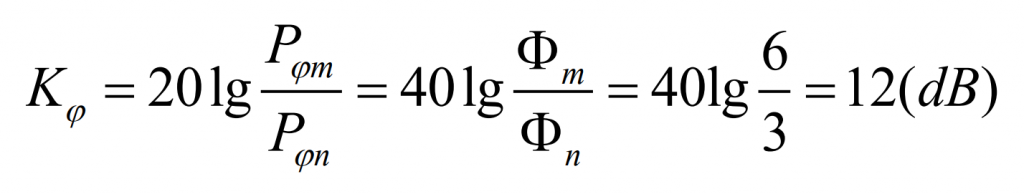

According to the formula, Φ 6 and Φ 3 dB value of the difference between flat bottom holes.

As shown in the figure, there is a defect near the nozzle of the cast steel joint, and figure (b) is the waveform diagram of the defect. In the lower part of the waveform, the clutter is ignored, and the last sharp wave is the bottom wave.