Casting shrinkage is a common phenomenon encountered in metal casting processes. It refers to the reduction in dimensions of a casting as it cools from its molten state to room temperature. Understanding the causes, effects, and mitigation strategies of casting shrinkage is crucial for producing high-quality castings with accurate dimensions and structural integrity. This article provides a comprehensive overview of casting shrinkage, delving into its causes, effects on casting properties, and effective strategies to mitigate its impact.

- Causes of Casting Shrinkage: Explore the various factors that contribute to casting shrinkage, including solidification shrinkage, liquid shrinkage, and pattern or mold material properties. Understand the influence of alloy composition, cooling rate, mold design, and pouring temperature on the occurrence of shrinkage defects.

- Effects of Casting Shrinkage: Learn about the detrimental effects of casting shrinkage on the final product. Understand how shrinkage defects, such as shrinkage porosity, microporosity, and dimensional inaccuracies, can compromise the mechanical properties, structural integrity, and functionality of the casting.

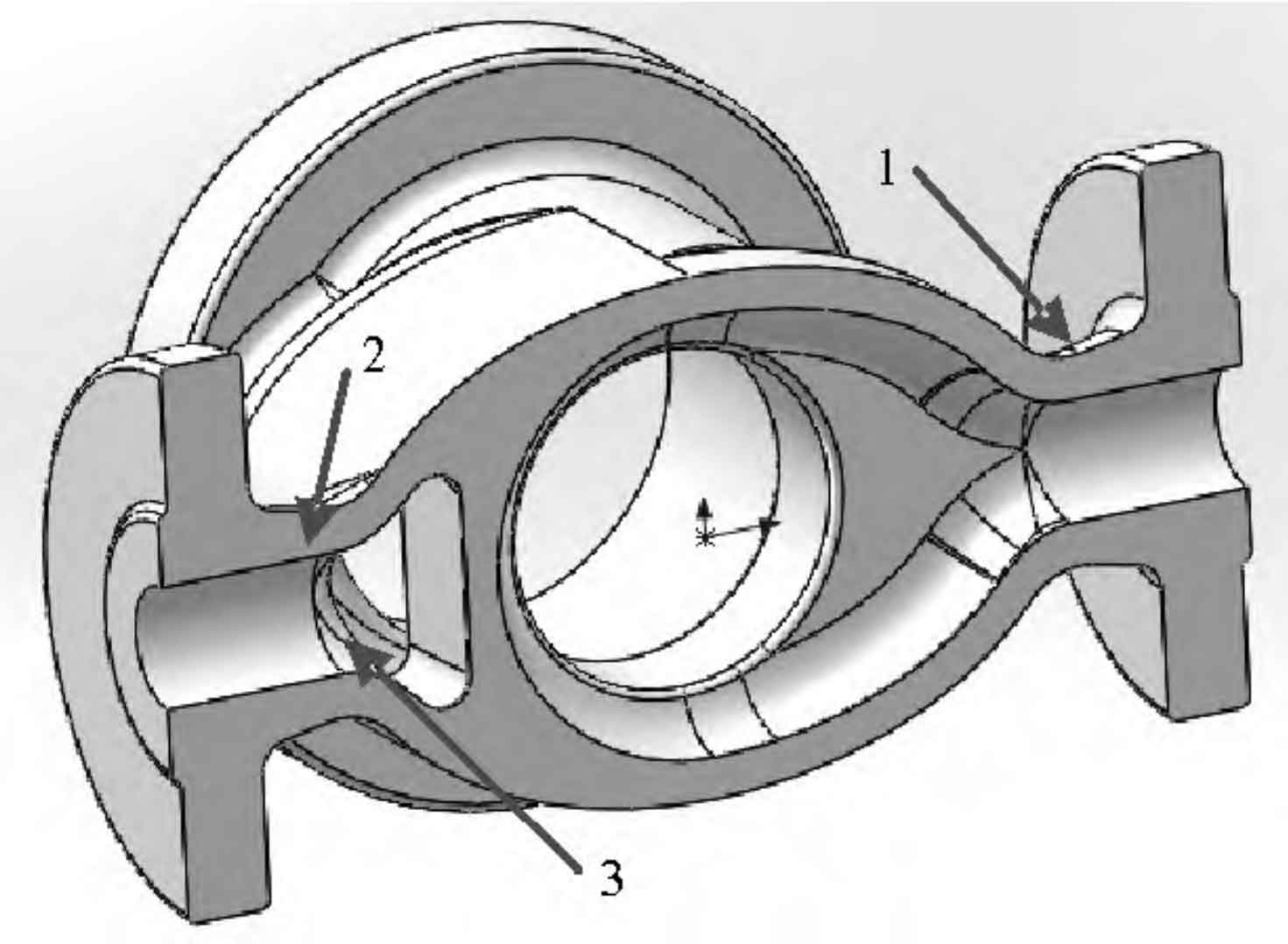

- Mitigation Strategies: Discover effective strategies and techniques to mitigate casting shrinkage and minimize its impact. Explore the use of feeding systems, risers, and gating design optimization to ensure proper feeding of molten metal and compensate for shrinkage. Learn about the benefits of modifying alloy compositions, applying heat treatment processes, and employing solidification simulation tools to predict and control shrinkage defects.

- Process Optimization: Understand the importance of process optimization in minimizing casting shrinkage. Explore the role of proper mold and core materials, optimized pouring and cooling rates, and controlled solidification in reducing the occurrence and severity of shrinkage defects. Learn about the significance of accurate dimensional control and post-casting inspection techniques in ensuring the quality of castings.

- Advanced Techniques and Technologies: Discover the advancements in casting technologies and techniques that aid in mitigating casting shrinkage. Learn about the application of computer-aided design (CAD) and computer-aided engineering (CAE) tools, such as casting simulation software, in predicting and analyzing shrinkage defects. Explore the use of advanced heat treatment methods, such as precision-controlled cooling, to minimize shrinkage and distortion.

- Quality Control and Inspection: Understand the importance of quality control measures and inspection techniques in detecting and addressing casting shrinkage defects. Learn about non-destructive testing (NDT) methods, such as X-ray imaging, ultrasonic testing, and visual inspection, in identifying shrinkage porosity and other internal defects.

By gaining a comprehensive understanding of casting shrinkage, its causes, effects, and effective mitigation strategies, foundry professionals, engineers, and researchers can enhance the quality and reliability of castings. Implementing proper process controls, optimization techniques, and advanced technologies can minimize shrinkage defects and ensure the production of dimensionally accurate and structurally sound castings.