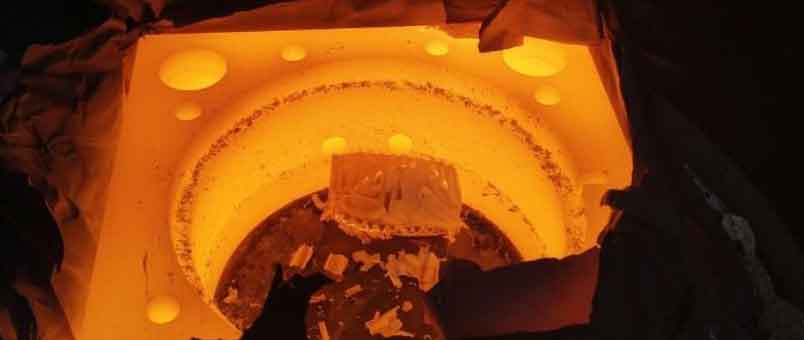

Stains and discolorations on the surface of heat-treated components can occur due to various factors during the heat treatment process. These surface imperfections can impact the aesthetics, corrosion resistance, and sometimes even the mechanical properties of the treated parts. Here are some common causes and potential solutions for stains and discolorations in heat treatment:

- Oxidation:

- Cause:

- Exposure of the component surface to oxygen during the heat treatment process can result in oxidation, leading to the formation of oxides and discoloration.

- Solution:

- Utilize controlled atmospheres: Conduct heat treatment in controlled atmospheres, such as inert gases (e.g., nitrogen or argon) or reducing atmospheres, to minimize the contact of the component surface with oxygen.

- Protective coatings: Apply protective coatings, such as graphite or other suitable materials, to the component surface before heat treatment to prevent direct oxidation.

- Cause:

- Scaling:

- Cause:

- Scaling occurs when the component surface reacts with the heat treatment atmosphere or quenching media, leading to the formation of thick and adherent oxide layers.

- Solution:

- Use suitable quenching media: Select quenching media that minimize the likelihood of scaling. For example, polymer quenchants or specialized oil formulations can be employed to reduce scaling tendencies.

- Implement post-treatment cleaning: Employ post-treatment cleaning methods, such as acid pickling or abrasive cleaning, to remove the oxide scale from the surface.

- Cause:

- Decarburization:

- Cause:

- Decarburization refers to the loss of carbon from the surface layer of the component during heat treatment, resulting in a lower carbon content and discoloration.

- Solution:

- Control atmosphere composition: Ensure the heat treatment atmosphere has the appropriate carbon potential to prevent excessive decarburization. Adjust the carbon potential, time, and temperature parameters accordingly.

- Modify process parameters: Optimize the heat treatment parameters, such as temperature and time, to minimize the depth and severity of decarburization.

- Cause:

- Contamination:

- Cause:

- Contaminants present on the component surface, such as oils, greases, or dirt, can lead to discoloration or stains during heat treatment.

- Solution:

- Thorough cleaning: Clean the component surfaces thoroughly before heat treatment to remove any contaminants that may cause discoloration. Utilize suitable cleaning methods such as degreasing or solvent cleaning.

- Cause:

- Interactions with Quenching Media:

- Cause:

- Certain quenching media can react with the component surface, resulting in stains or discoloration.

- Solution:

- Quenching media selection: Choose quenching media that minimize the potential for surface interactions and staining. Consider using specialized quenchants or controlled cooling methods to reduce surface staining.

- Cause:

- Surface Reaction with Fixtures or Containers:

- Cause:

- Interaction between the component surface and fixtures, trays, or containers used during heat treatment can lead to staining or discoloration.

- Solution:

- Proper surface protection: Apply suitable protective coatings or use barrier materials between the component surface and fixtures/containers to prevent direct contact and surface reactions.

- Cause:

- Quality Control and Inspection: Conduct regular quality control inspections, including visual examination, to detect any stains or discolorations early. Implement non-destructive testing techniques, such as dye penetrant testing or surface roughness measurements, to assess the extent and severity of surface imperfections.

It’s important to note that the specific causes and solutions for stains and discolorations may vary depending on the heat treatment process, materials used, and specific conditions. Collaboration with heat treatment experts, metallurgists, and quality control personnel can provide valuable insights and guidance for addressing stains and discolorations in heat treatment effectively.