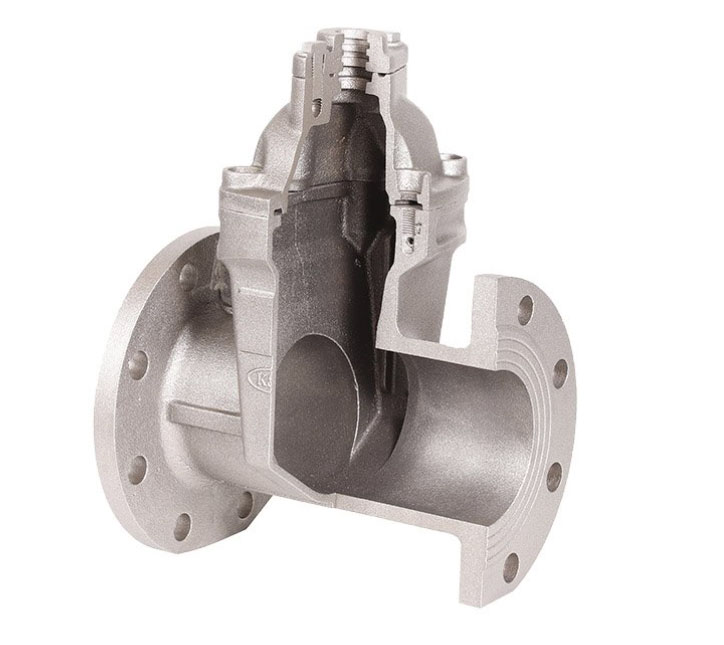

Gate valves are commonly used in various industries to regulate the flow of fluids in piping systems. The gate valve body serves as the main housing for the valve, providing structural support and containing the essential components that enable its operation. Understanding the anatomy of a gate valve body and its key components and functions is crucial for proper installation, maintenance, and overall valve performance.

- Body Casing: The body casing is the outer shell of the gate valve. It provides structural integrity and houses all the internal components. It is typically made of durable materials such as cast iron, cast steel, or stainless steel, depending on the application and fluid compatibility requirements.

- Bonnet: The bonnet is the top portion of the gate valve body and serves as a cover for the internal components. It is usually bolted or screwed onto the body casing, creating a seal to prevent leakage. The bonnet may also house additional components such as stem packing and gland followers.

- Gate: The gate is a movable component that controls the flow of fluids within the valve. It is positioned inside the valve body and can be raised or lowered to open or close the flow passage. The gate is typically made of metal, such as cast iron, cast steel, or stainless steel, and is designed to fit tightly against the valve seats to minimize leakage when closed.

- Seats: Seats are the sealing surfaces located on either side of the gate within the valve body. They create a tight seal against the gate when the valve is closed, preventing fluid leakage. Seats are typically made of materials like resilient materials such as rubber, elastomers, or metal alloys, depending on the application and fluid characteristics.

- Stem: The stem is a slender rod connected to the gate. It extends from the top of the gate valve body through the bonnet. The stem allows for the opening and closing of the gate by rotating or linear motion, depending on the valve design. The stem is typically made of corrosion-resistant materials such as stainless steel or bronze.

- Gland: The gland is a packing gland located around the stem where it passes through the bonnet. It houses packing material, such as graphite or PTFE, which forms a seal around the stem to prevent leakage. The gland can be tightened or adjusted to maintain the desired level of packing compression.

- Handwheel or Actuator Mounting: Gate valves can be manually operated using a handwheel or actuated using pneumatic, hydraulic, or electric actuators. The gate valve body is designed to accommodate the mounting of these mechanisms, allowing for remote or automated operation of the valve.

Understanding the key components and functions of a gate valve body is essential for proper installation, maintenance, and troubleshooting. By familiarizing oneself with the anatomy of a gate valve body, operators can effectively operate and maintain gate valves, ensuring reliable and efficient fluid flow control in various industrial applications.