Understanding the metallurgy of Spheroidal Graphite Cast Iron (SGCI), also known as ductile iron, is crucial for its wide range of industrial applications. The unique metallurgical properties of Spheroidal Graphite Cast Iron arise from its distinct microstructure, which includes spherical graphite nodules in a ferritic or pearlitic matrix. Let’s delve into the key aspects of Spheroidal Graphite Cast Iron’s metallurgy and how it translates to industrial applications.

Key Metallurgical Aspects

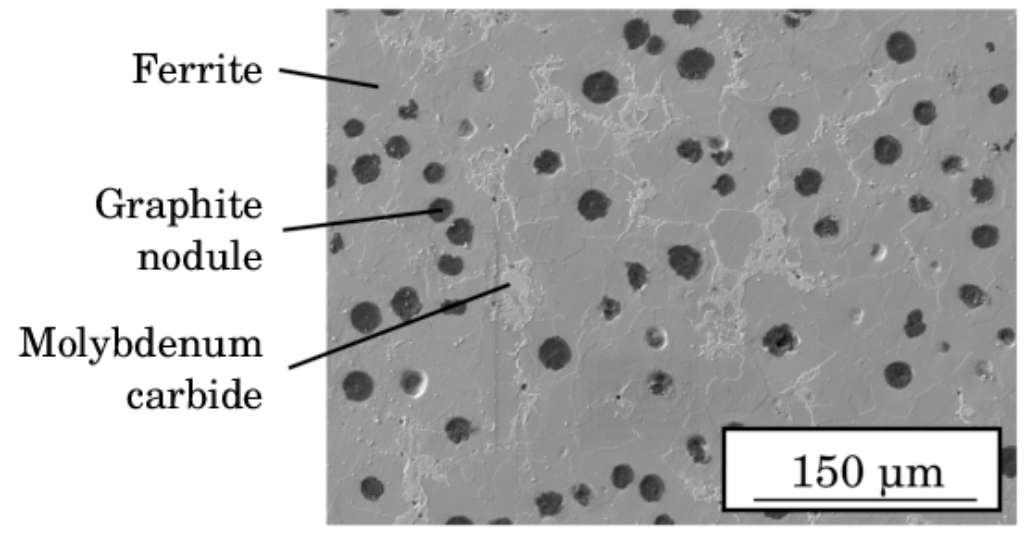

- Graphite Nodules: The defining feature of Spheroidal Graphite Cast Iron is its graphite nodules. Unlike the flake graphite in gray cast iron, these spherical nodules create less stress concentration points in the metal matrix, enhancing tensile strength and ductility.

- Matrix Structure: The matrix of Spheroidal Graphite Cast Iron can either be ferritic (softer and more ductile) or pearlitic (harder and stronger), or a combination of both. The matrix type influences the mechanical properties of the cast iron, and it can be controlled through heat treatment and alloying.

- Nodulizing Elements: The formation of spherical graphite nodules is induced by adding nodulizing agents like magnesium or cerium to the molten iron. These elements react with sulfur and oxygen in the melt to promote the spheroidal graphite formation.

- Heat Treatment: Spheroidal Graphite Cast Iron can undergo various heat treatments, including annealing, normalizing, and austempering. Austempering, in particular, transforms the matrix to a bainitic structure, significantly improving strength and wear resistance.

Industrial Applications

- Pipes and Fittings: Spheroidal Graphite Cast Iron’s excellent strength, ductility, and corrosion resistance make it ideal for water and sewage pipes, as well as fittings. These applications take advantage of Spheroidal Graphite Cast Iron’s ability to withstand high internal pressures and external loads.

- Automotive Components: Spheroidal Graphite Cast Iron is widely used in the automotive industry for manufacturing engine parts, suspension components, and brake systems. The material’s fatigue resistance and ability to absorb vibrational energy are crucial here.

- Heavy Machinery: The strength and wear resistance of Spheroidal Graphite Cast Iron are beneficial in heavy machinery, particularly in mining and construction equipment. Gears, sprockets, and hydraulic components made of Spheroidal Graphite Cast Iron can withstand high stress and abrasive environments.

- Wind Turbines: Components like hubs and gearbox housings in wind turbines are often made from Spheroidal Graphite Cast Iron. The material’s good fatigue resistance is critical in these applications, where components are subjected to cyclic loads.

Future Prospects in Metallurgy

- Advanced Alloying: Continued research into alloying Spheroidal Graphite Cast Iron with elements like nickel, copper, and chromium could yield materials with even better mechanical properties and corrosion resistance.

- Microstructure Refinement: Techniques for refining the size and distribution of graphite nodules and the matrix structure are key areas of research, aiming to further enhance the mechanical properties.

- Sustainable Production: Developing more environmentally friendly production methods, including energy-efficient melting and recycling of Spheroidal Graphite Cast Iron, is becoming increasingly important.

- Additive Manufacturing: The potential of 3D printing Spheroidal Graphite Cast Iron opens new avenues for complex component fabrication, which could revolutionize design and manufacturing processes in various industries.

Understanding and advancing the metallurgy of Spheroidal Graphite Cast Iron is pivotal for its continued use and development in industrial applications. Its unique combination of strength, ductility, and cost-effectiveness makes it an invaluable material in a wide array of industrial settings.