Casting defects are common occurrences in the casting process that can affect the quality and integrity of the final product. It is important to understand these defects to identify their causes and implement appropriate solutions. Let’s explore some common casting defects:

- Gas Porosity:

- Cause: Gas porosity is caused by the entrapment of gases, such as hydrogen or nitrogen, in the molten metal during solidification.

- Appearance: Gas porosity appears as small spherical or elongated voids or bubbles on the surface or within the casting.

- Solution: Proper degassing techniques, maintaining a clean and dry environment, and using suitable molding and core materials can help minimize gas porosity.

- Shrinkage:

- Cause: Shrinkage defects occur due to the uneven solidification and subsequent contraction of the molten metal.

- Appearance: Shrinkage defects appear as localized depressions or voids on the casting surface or as internal cracks.

- Solution: Designing proper risering and gating systems, using feeding aids like risers or chills, and optimizing the cooling rate can help prevent shrinkage defects.

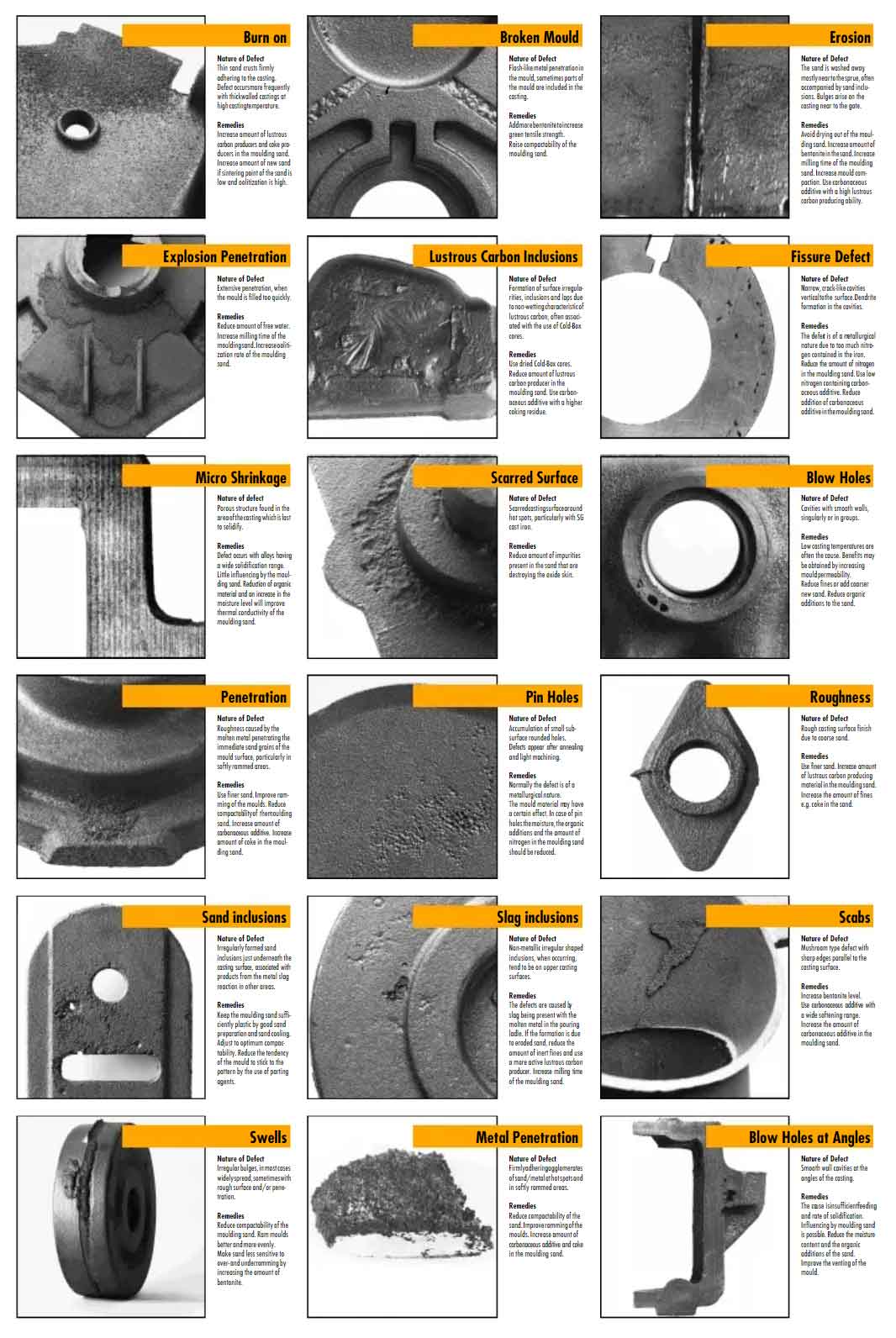

- Inclusions:

- Cause: Inclusions are foreign particles or impurities that are trapped in the molten metal and become embedded in the casting.

- Appearance: Inclusions can appear as dark or light spots, streaks, or irregularly shaped particles on the casting surface or within the structure.

- Solution: Proper handling and preparation of molding materials, effective filtration systems, and adequate metal refining processes can reduce inclusion defects.

- Cold Shut:

- Cause: Cold shut defects occur when two or more streams of molten metal do not fuse properly during solidification, resulting in an incomplete joint.

- Appearance: Cold shut defects appear as visible lines or cracks on the casting surface.

- Solution: Ensuring proper gating and risering design, controlling the pouring temperature and rate, and optimizing the mold filling process can prevent cold shut defects.

- Misruns:

- Cause: Misruns happen when the molten metal fails to completely fill the mold cavity, resulting in an incomplete casting.

- Appearance: Misruns appear as partially filled or incomplete sections of the casting.

- Solution: Optimizing the mold design, improving the flowability of the molten metal, and ensuring proper gating and risering systems can help prevent misruns.

- Sand Inclusion:

- Cause: Sand inclusion occurs when loose sand particles or mold material become embedded in the casting.

- Appearance: Sand inclusion defects appear as sandy or rough patches on the casting surface.

- Solution: Improving the quality and compactness of the molding sand, applying suitable coatings or parting agents, and using effective mold shaking or vibrating techniques can minimize sand inclusion defects.

These are just a few examples of common casting defects. Other defects such as hot tears, surface roughness, flash, and warpage can also occur. To address these defects, a combination of process optimization, quality control measures, and continuous improvement initiatives should be implemented.

By understanding and addressing common casting defects, manufacturers can improve the overall quality, reliability, and performance of castings, ensuring that they meet the desired specifications and requirements.