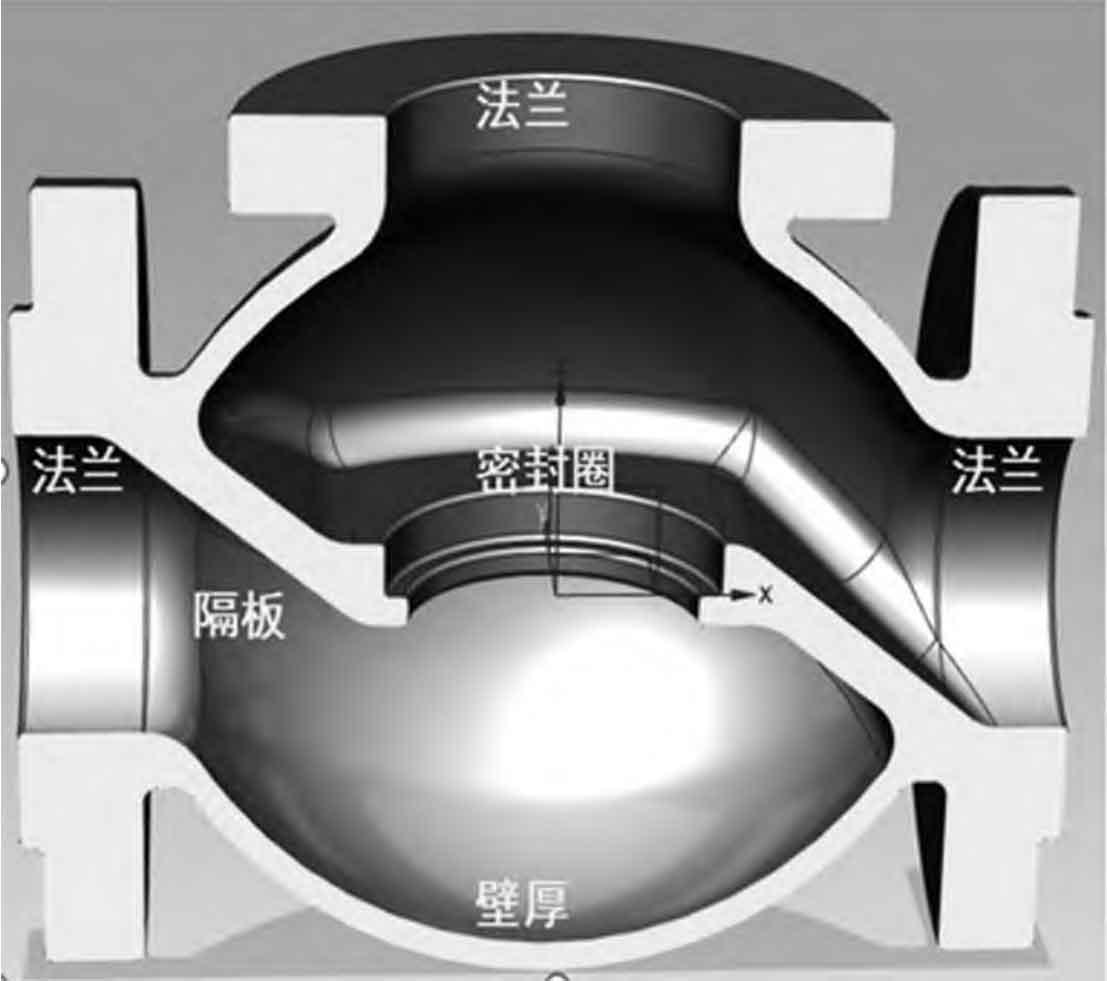

Producing high-quality stainless steel valve body castings via lost foam casting demands meticulous control across every stage. My experience demonstrates that optimizing foam patterns, coating systems, gating design, and pouring parameters directly impacts dimensional accuracy and pressure integrity in these critical components.

Material Selection and Pattern Formation

Pattern quality dictates the final valve body casting surface finish. For stainless steel, low-carbon EPMMA (60% C) or STMMA (EPS/EPMMA blend) minimizes carbon pickup and reduces gas evolution. Critical parameters include:

| Parameter | Value Range | Impact on Valve Body Casting |

|---|---|---|

| Bead Size | 0.4–0.6 mm | Dictates minimum wall thickness (5 mm) |

| Pre-expansion Density | 25–28 g/L | Higher density reduces distortion risk |

| Steam Pressure | 0.10–0.15 MPa | Ensures uniform bead fusion |

| Dwell Time | 100–120 s | Prevents under-fusion or collapse |

Pattern extraction requires controlled air pressure (<0.3 MPa) perpendicular to parting lines. Cooling duration ($t_c$) relates to wall thickness ($W_t$) in mm:

$$ t_c = k \cdot W_t^{1.5} \quad (k = 2.5–3.0) $$

Gating System Optimization

Bottom-gating is essential for valve body castings with thick-thin transitions (5–18 mm). Gating dimensions exceed conventional alloys to counter stainless steel’s poor fluidity. For a cluster of four DN100 valve bodies (12 kg each):

| Component | Dimensions (mm) | Function |

|---|---|---|

| Ingate | 10 × 35 | Feeds flange thick sections |

| Runner | 40 × 30 | Distributes metal, traps slag |

| Sprue | Ø50 | Minimizes aspiration, controls flow |

Clustering efficiency ($\eta_c$) depends on yield ($Y$) and number of patterns ($N$):

$$ \eta_c = \frac{Y}{N} \times 100\% \quad (Target: >75\%) $$

Coating Technology and Drying

Coatings balance gas permeability ($P_g$) and barrier strength. A typical refractory slurry composition includes:

| Component | wt.% | Role |

|---|---|---|

| Zircon Flour | 45–50 | Refractoriness |

| Sodium Silicate | 3–5 | Green strength |

| CMC | 0.3–0.5 | Suspension |

| Surfactant | 0.1–0.2 | Wetting |

Optimal viscosity: 45–55 sec (Ford Cup #4). Drying requires 45–50°C with <30% RH. Drying time ($t_d$) in hours correlates with pattern mass ($M_p$) in kg:

$$ t_d = 15 + 8M_p $$

Pouring and Solidification Control

Stainless steel (304) pouring demands strict protocols:

- : 30–50 Hz frequency compacts 40–70 mesh silica sand

- Vacuum: 0.60–0.65 MPa minimizes gas entrapment in the valve body casting

- Pouring Rate: 1.2–1.5 kg/sec to avoid turbulence

Critical pressure-holding time ($t_h$) post-pour depends on maximum casting thickness ($T_{max}$) in mm:

$$ t_h = 2.5T_{max} + 2 \quad (\text{minutes}) $$

Premature vacuum release (<80% solid fraction) causes shrinkage porosity in the valve body casting.

Quality Validation

Final valve body castings undergo rigorous testing:

| Test | Standard | Acceptance Rate |

|---|---|---|

| Hydrostatic | 1.5× working pressure | 90% |

| Helium Leak | <10⁻⁴ mbar·L/sec | 65% |

| Surface Finish | Ra 12.5–25 μm | 98% |

Dimensional tolerances consistently achieve ISO 8062 CT8-10. Process refinements focus on improving leak-tightness in complex valve body castings through directional solidification enhancements.