In recent years, with the continuous development of ship design software, 3D design technology has gradually become an important means to improve ship research and development efficiency and product quality. In China, based on the self-developed SPD (ShipProductDesign) using CAD and imported software such as Tribon and NAPA, some achievements have been made in the research of ship 3D design technology. However, the current design and construction of ship steel castings still mainly rely on two-dimensional drawings. This method not only has low design efficiency, but also is difficult to overcome the problems of traditional two-dimensional design, such as a single perspective, difficult to distinguish line overlap, and large curvature changes in some areas, resulting in difficulty in component positioning and inaccurate weight estimation.

CATIA is a CAD/CAE/CAM integrated design software developed by French company Dassault. As an important component of PLM (Product Lifecycle Management) collaborative solutions, CATIA adopts advanced hybrid modeling technology, provides rich modeling tools and powerful surface design modules, and is widely used in fields such as aerospace, automotive, engineering and construction, and consumer goods. At present, the CATIAV6 version provides relatively complete ship modules, which have been promoted and applied in multiple shipyards and ship design institutes in China. With the continuous deepening of CATIA application in China’s shipbuilding industry, we are considering using the 3DE platform CATIA 3D modeling software. Taking the bow column steel castings of ships as an example, we propose a method for designing and generating ship steel castings in a 3D environment. By conducting three-dimensional modeling of ship steel castings, the collaborative design of ship structure and ship steel castings is achieved, improving the design and construction efficiency of ship steel castings such as bow columns, stern tube, and stern frame, as well as the accuracy of estimating the weight and center of gravity of these steel castings.

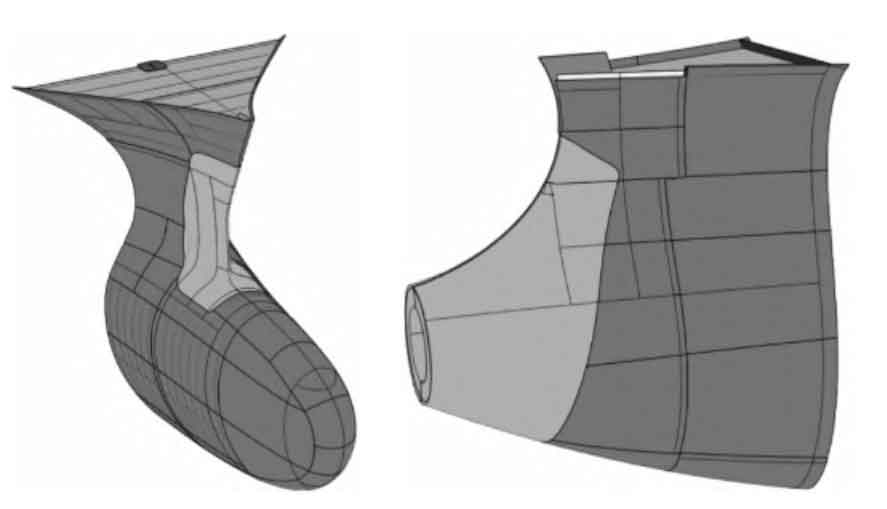

The 13000t heavy lift vessel is a multi-purpose heavy lift vessel capable of loading various types of goods such as containers, bulk cargo, and special equipment. Its hull structure design includes the design of cast steel components such as bow columns and stern tubes. This article takes the CATIA 3D modeling design of the bow column steel castings of a 13000t heavy lifting vessel as an example to introduce a 3D design modeling method for ship steel castings based on CATIA.