The chemical composition (mass fraction, the same below) of 5083 aluminum alloy plate is: 0.4% – 1.0% Mn, 4.3% – 5.2% Mg, 0.05% – 0.25% Cr, < 0.40% Fe, < 0.40% Si, < 0.10% Cu, < 0.25% Zn, < 0.15% Ti, and the remaining is al. The process flow is: smelting → refining → casting → homogenization annealing → head and tail cutting → horizontal cutting into plates → packaging.

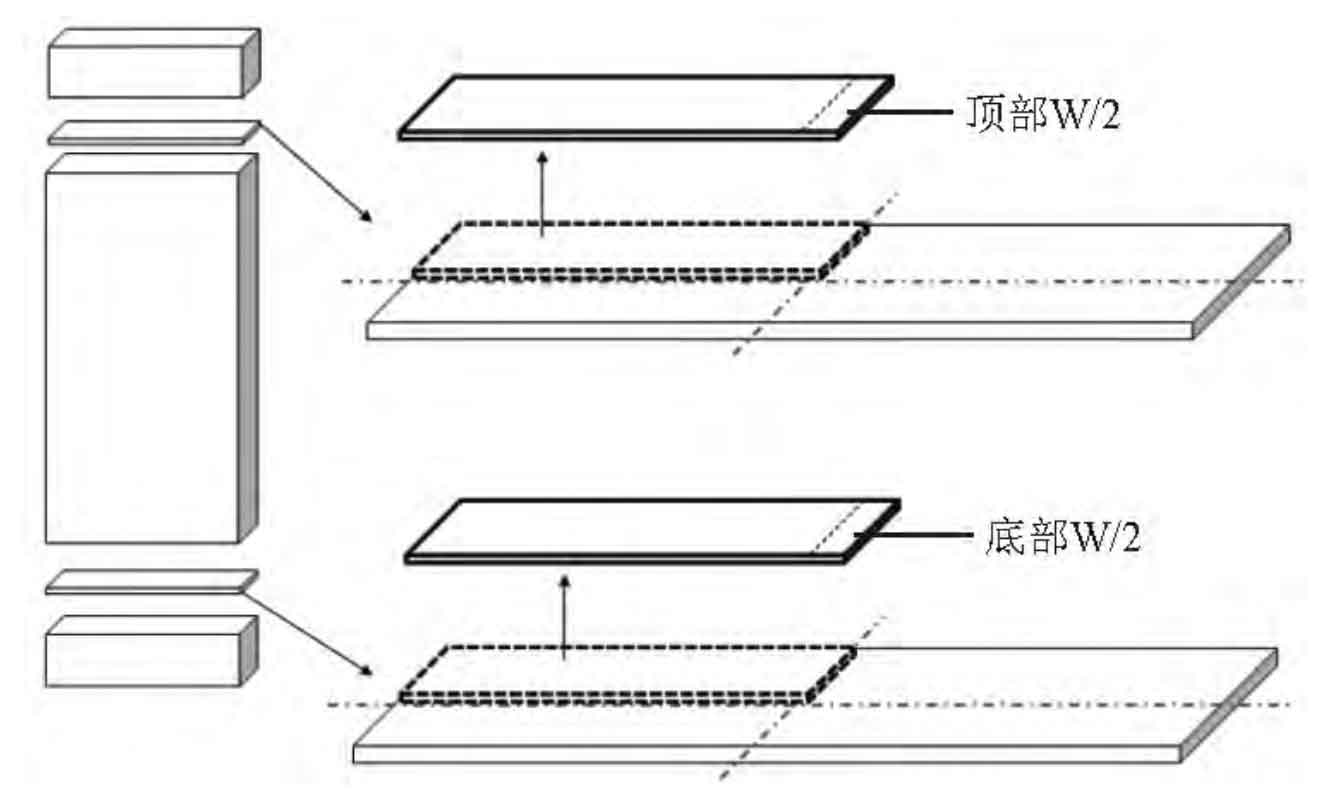

Multix + sn5500 phased array ultrasonic instrument and water immersion phased array ultrasonic probe with frequency of 5MHz, probe chip number of 256, chip width of 0.6mm, chip spacing of 0.1mm and chip height of 10mm are used to complete the water immersion ultrasonic wave inspection of ingots according to GB / t6519-2013a, Analyze the distribution law of ingot discontinuity. The ingot is sampled (see Figure 1), and then the anodic oxidation test is carried out. The anodic oxidation process is as follows: degreasing (30g / L neutral degreasing powder aqueous solution, 50 ± 5 ℃, soaking for 5min) → water washing → alkaline washing (80 ~ 100g / L, 1 ~ 2min) → water washing → neutralization (HNO3, H2O volume ratio is 3:7, 5 ~ 8min) → water washing → oxidation (H2SO4, H2O mass ratio is 2:8, 25 ~ 30min) → hole sealing (water temperature 80 ℃, 5 ~ 8min). Take samples of anodic oxidation samples, grind and polish them one by one with metallographic sandpaper No. 400, 600, 800 and 1000, and then electropolish them with perchloric acid alcohol solution with a volume fraction of 10%. The structure was analyzed by axioobserver3m optical microscope, the surface morphology of the defect was observed by evo18 scanning electron microscope, and the micro component of the defect was analyzed by the attached Oxford energy spectrometer.