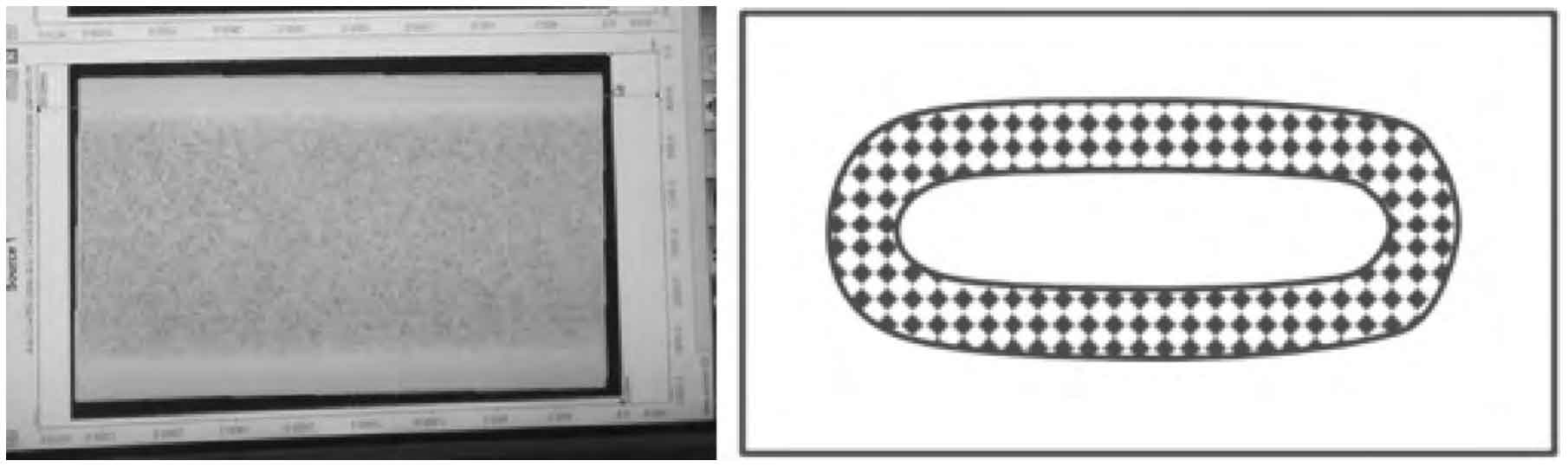

As shown in the figure, the ultrasonic scanning diagram of aluminum alloy plates with class a over standard defects is shown. The roughness of milled surface with water immersion ultrasonic testing equipment is better than ra3.2 μ 5083 ingot of M is scanned by ultrasonic, as shown in Figure a.

According to the analysis of C-scan data, the low ultrasonic echo equivalent on both sides of the ingot is regarded as the normal area, the ultrasonic equivalent near the centerline exceeds 100% of the ultrasonic equivalent in the normal area, and there is no discontinuity with large equivalent near the two small planes on the side of the ingot, as shown in Figure C. The ultrasonic A-scan and B-scan were carried out for the area on the centerline with high ultrasonic equivalent. When the probe was placed above the center line of the ingot, it was found that there was 100% ultrasonic noise equivalent higher than the normal area near the 1 / 4 thickness area of the ingot, and the noise A-scan waveform was in the shape of double steamed bread peaks. Therefore, it can be seen that the discontinuity was symmetrically distributed in the height of the thickness section, as shown in Figure B. Based on the analysis results of a, B and C scanning data, it is inferred that the ingot cross section is elliptical ring, and the distribution law of discontinuity is shown in Figure D.