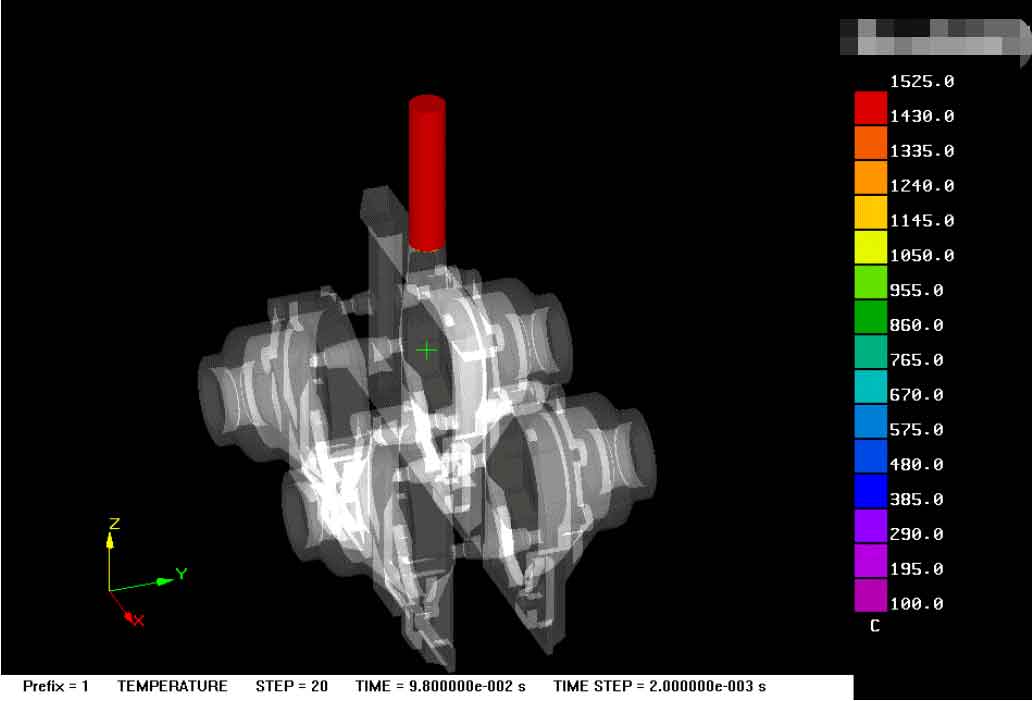

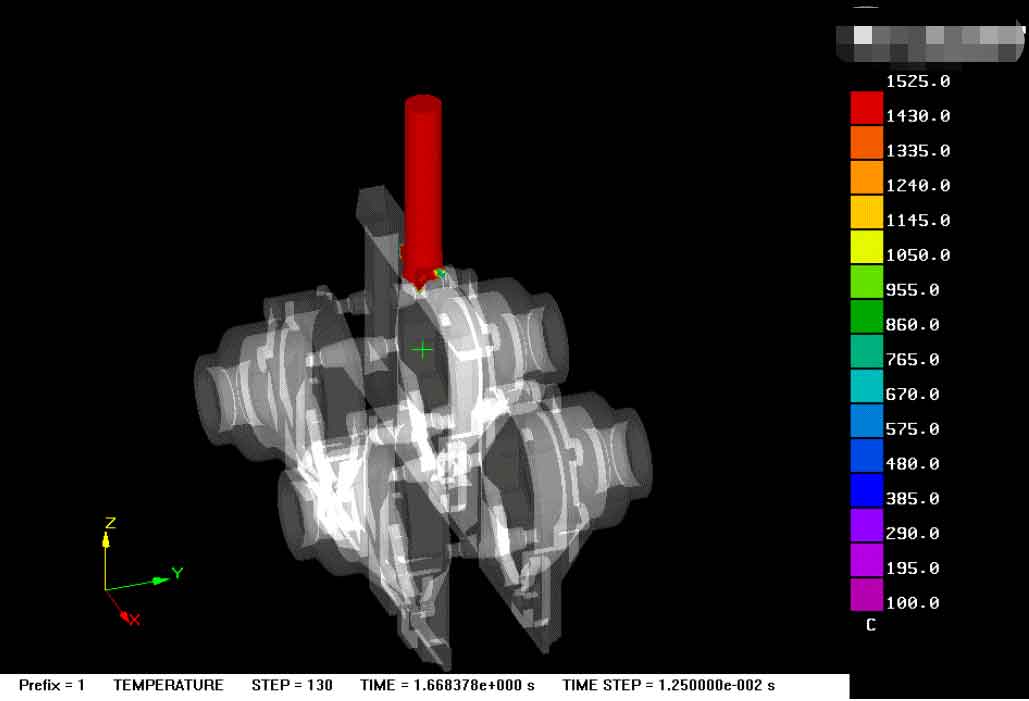

The numerical simulation of lost foam casting filling process is shown in the figure. The whole filling process is stable without serious splash and obvious wall attachment. The red represents the metal liquid and the grey represents the foam shape. It can be seen that the foam filling and temperature drop phenomena at the filling front. Because the runner is hollow ceramic tube, so there is no foam in the sprue. From figure a, it can be seen that when 0.098s is filled with 2.57%, it only takes a very short time to fill the sprue. As can be seen from figure B, it takes 1.67s to fill the mold by 2.98%, and the molten metal can enter the runner at this moment. Figures a and b show that the foam pattern not only reduces the temperature of the molten metal at the filling front, but also hinders the flow of molten metal to a certain extent, so the filling speed of lost foam casting is much slower than that of traditional sand casting.

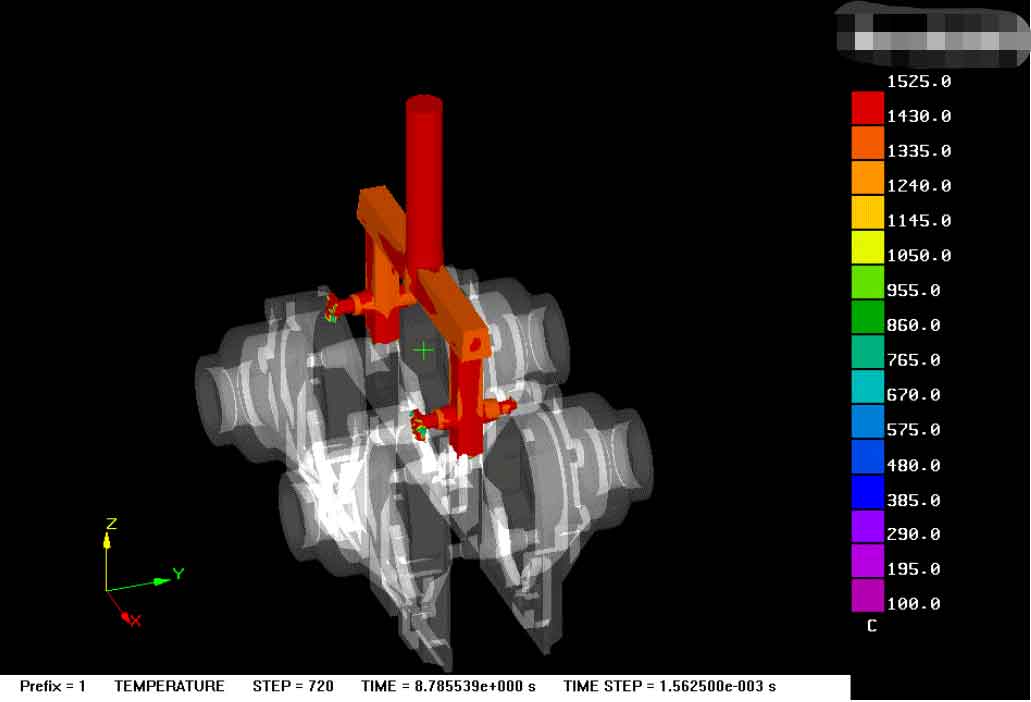

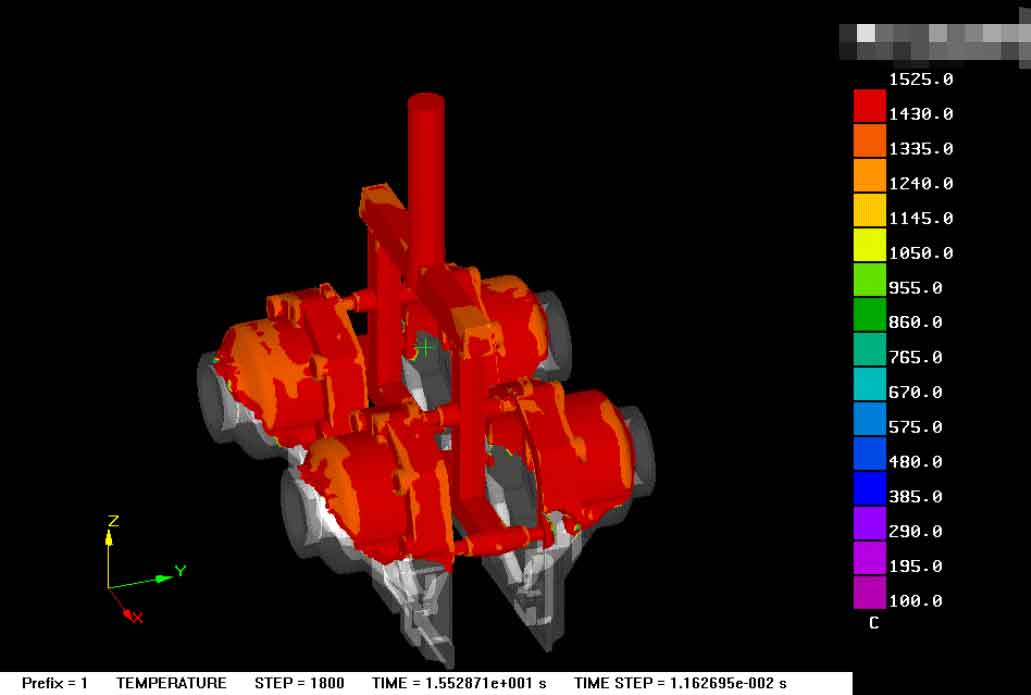

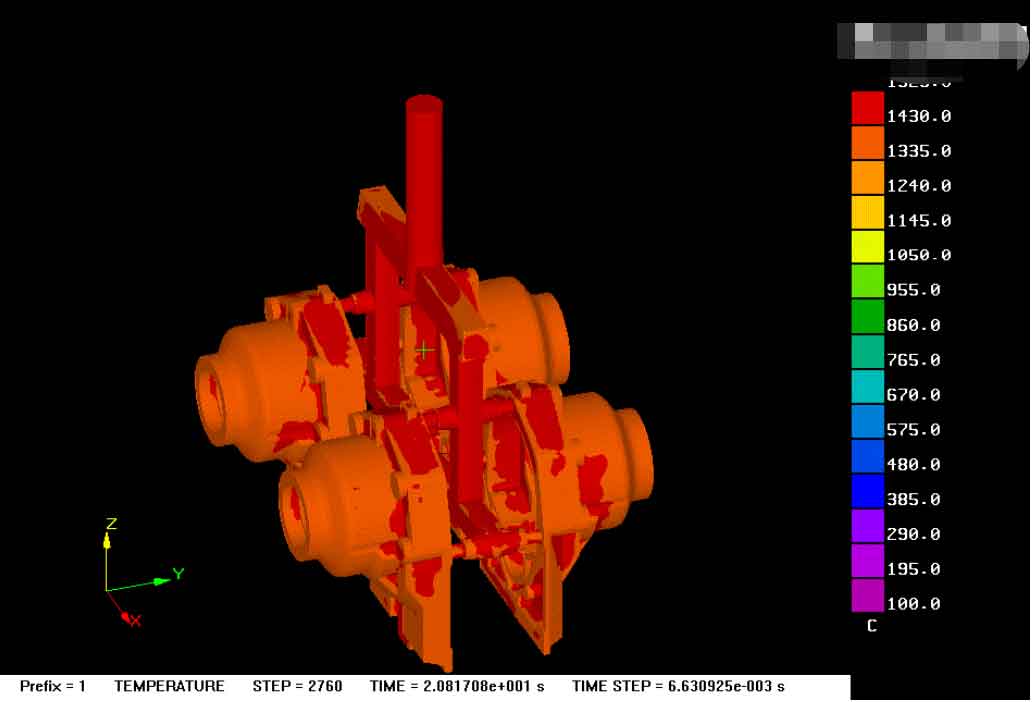

Figure C shows that at 9.78s, the upper sprue of the stepped gating system starts filling, and the filling is 11.46%. As can be seen from figure D, the lower sprue starts filling at 15.53s, and the filling is 50.02% at this time. When designing the gating system, the reason why the stepped gating system is selected is that the lower sprue starts to fill the mold first in the process of liquid metal filling, and more liquid metal is introduced. This will enable the foam pattern to burn from bottom to top, which will help to form a temperature gradient from the lower part of the lost foam casting to the gate gradually increasing, so as to establish a better sequence solidification condition for the lost foam casting. At the same time, the rising direction of the metal liquid is consistent with the direction of the gasifying product of the foam plastics, which is favorable for the exhaust investigation. Figure C and figure d show that this advantage of the stepped gating system is not shown, that is, the lost foam casting gating system does not achieve the design effect. As can be seen from figure e, the whole filling process took 20.82s.