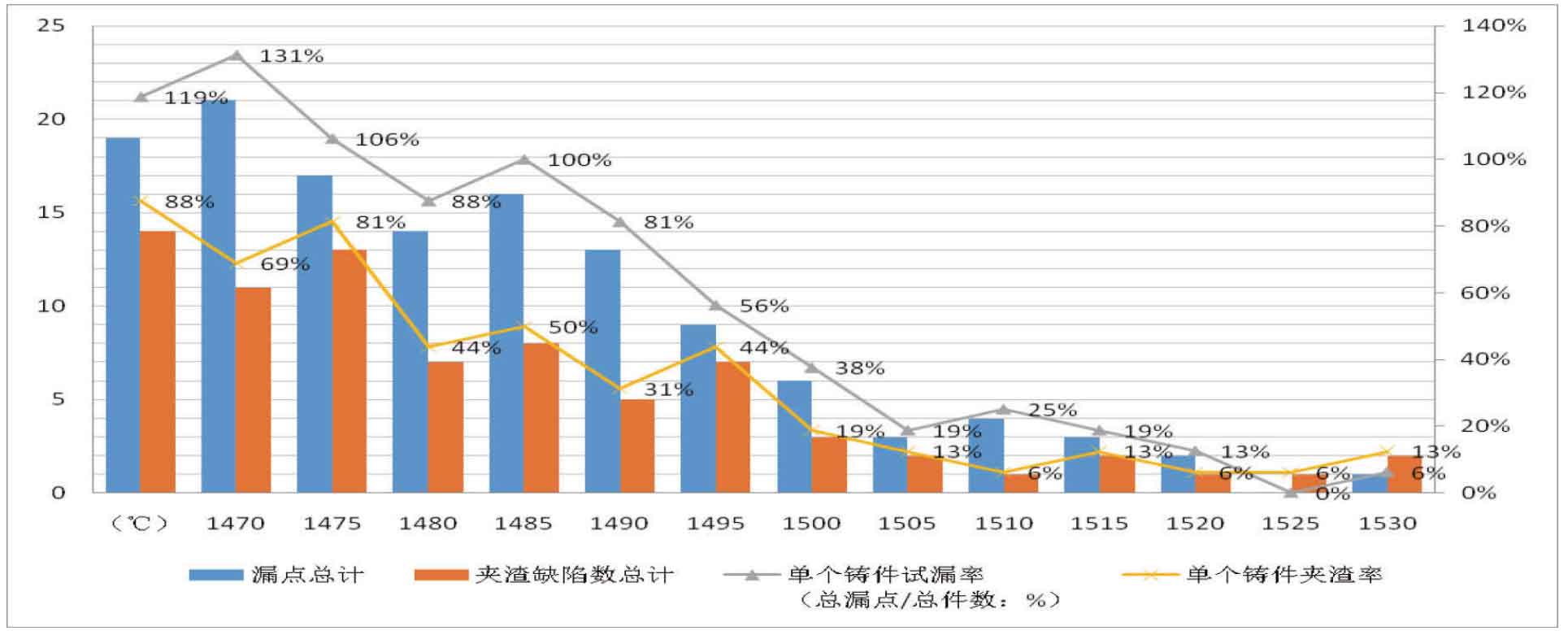

Referring to machine tool castings in the early stage, considering the factor of thin wall, the pouring temperature was increased by 30 ℃ and the pouring temperature was 1470 ℃. However, in the actual production, many thin-wall gray cast iron gearbox shell castings cast by lost foam casting have cold shut defects as shown in Figure 5, so we gradually increase the pouring temperature. The improved gating system design scheme is adopted for the lost foam casting thin-walled gray cast iron gearbox shell casting A. on the basis of 1470 ℃, the pouring temperature is divided into a group of 5 ℃ and two boxes are selected for each group (16 pieces are verified). The carbon equivalent is set to 3.8%. The qualification rate of hydraulic leakage test and slag inclusion defect rate are verified. The results are shown in Figure.

The verification results show that with the increase of pouring temperature, the water pressure leakage points and slag inclusion defects of lost foam casting thin-walled gray cast iron gearbox shell casting are gradually reduced, the pouring temperature reaches more than 1500 ℃, and the cold shut problem is completely solved. When the pouring temperature reaches more than 1520 ℃, the water pressure leakage rate and slag inclusion rate are reduced to the lowest, it is basically no longer improved.