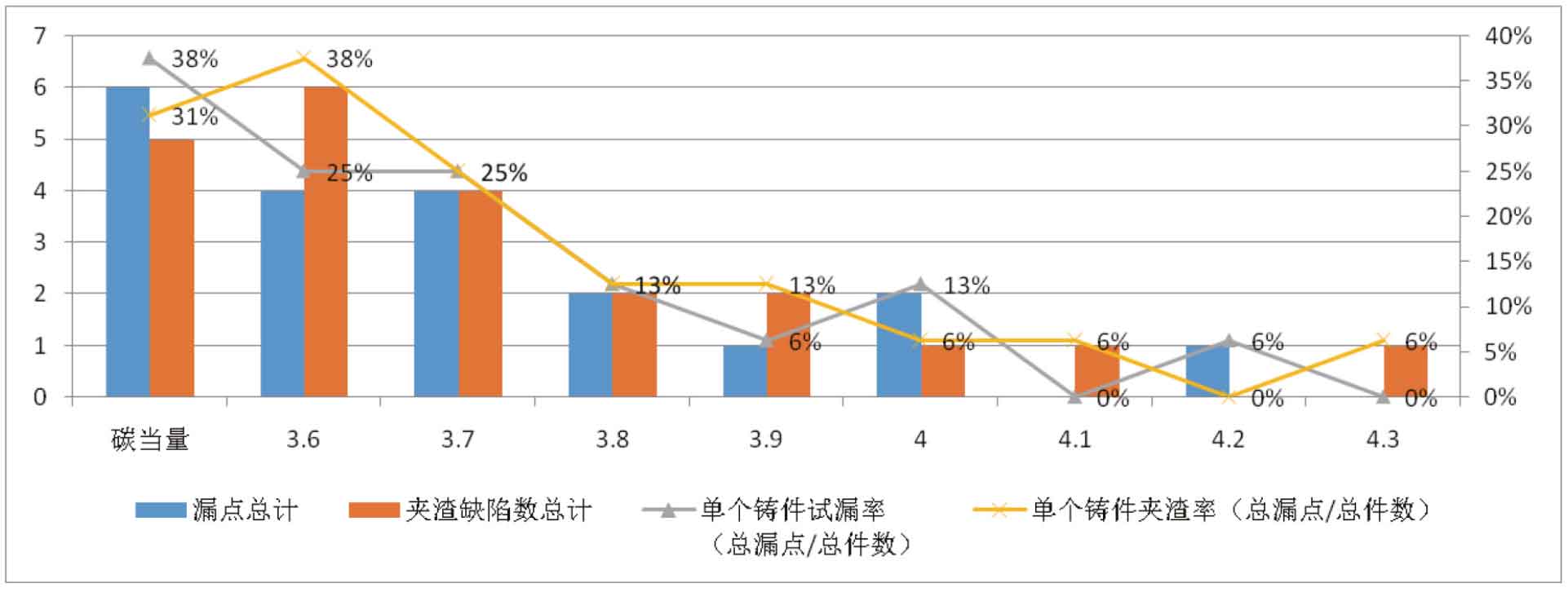

The defects can not be reduced to a qualified level by adjusting the pouring temperature. Therefore, lost foam casting thin-walled gray cast iron gearbox shell casting a is selected, the pouring temperature is kept at 1515 ~ 1525 ℃, the carbon equivalent is adjusted, and the carbon equivalent is gradually increased from 3.6% to 4.3% (the carbon equivalent of each group is increased by 0.1%, and there are 16 pieces in two boxes in each group). The leakage and slag inclusion defects of lost foam casting thin-walled gray cast iron gearbox shell casting are verified, and the results are shown in the figure.

The results show that with the increase of carbon equivalent, the water pressure leakage points and slag inclusion defects of lost foam casting thin-walled gray cast iron gearbox shell casting gradually reduce. When the carbon equivalent increases to 4.2%, the improvement effect of carbon equivalent is no longer obvious. Therefore, the carbon equivalent of smelting process is 4.1% (C content 3.5% + Si content 1.8%).