In order to effectively ensure the casting effect of automobile engine cylinder block, this time, taking the casting of an engine cylinder block of BMW China as an example, the application of casting technology is analyzed, including the analysis of cylinder block size requirements, top surface finishing process and cylinder hole finishing process. The following is the specific application of casting process:

1. Requirements for cylinder block size

This paper studies the casting technology of an engine block product of BMW. The main components of the engine block include the top surface of the cylinder block, cylinder hole and crankshaft hole.

2. Finishing process of top surface

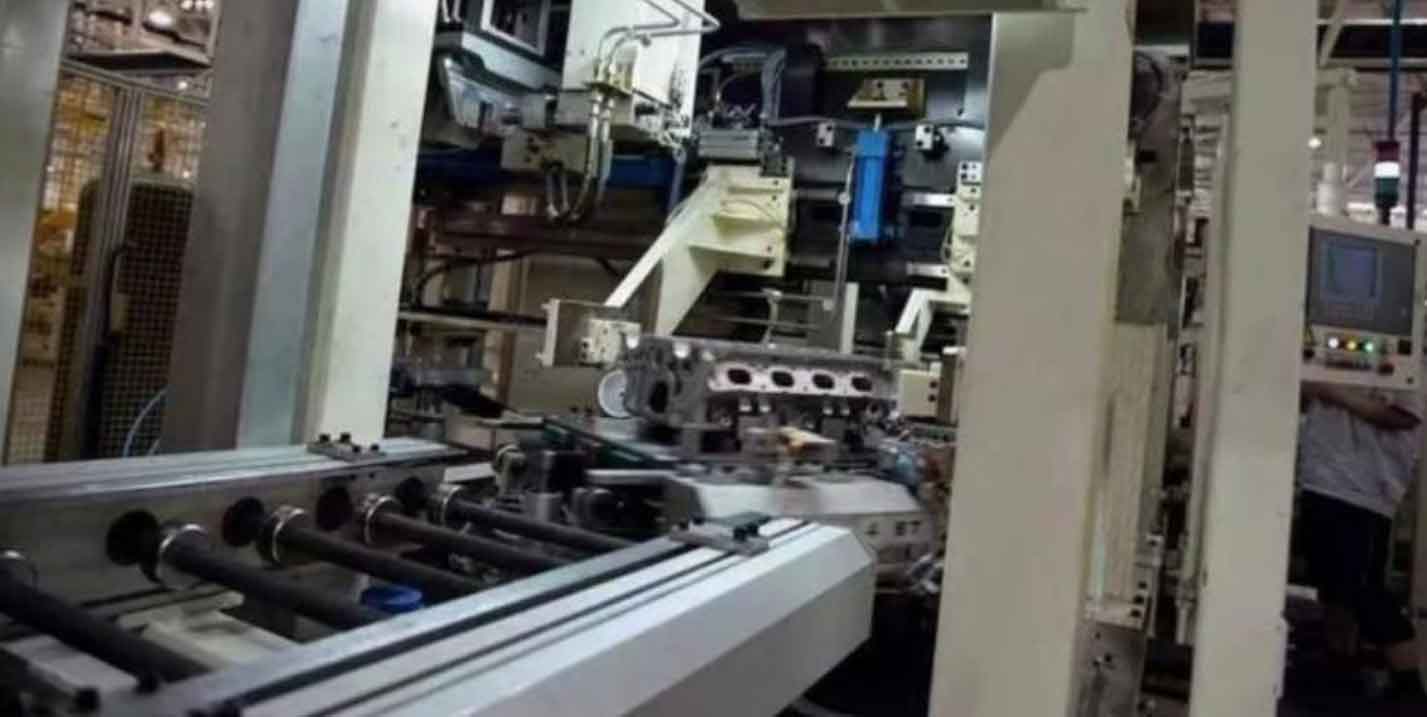

For the casting of automobile engine block, the top finish machining is a key content. Only by controlling the top finish machining process, can we effectively ensure its machining quality and meet its practical application needs. In the process of casting the top surface of the cylinder block, the finishing process includes the following points: first, carry out the clamping and positioning design of the cylinder block according to the drawing, because the drawing size is the bottom surface and its two locating pin holes, and the datum has been formed in the previous casting, so in the specific top surface processing, the accuracy error caused by datum conversion can be avoided. Second, because the cylinder block has a large space size, if the clamping is not tight during processing, it will lead to slight shaking of the cylinder block, which will have an adverse impact on its processing accuracy. Therefore, several self-locking clamping points and auxiliary support points need to be set on the fixture to keep the cylinder block clamping in a uniform stress state, so as to ensure the flatness of cylinder block casting. Third, in casting, it is necessary to do a good job in gas inspection of the processing center to ensure the processing stability. Fourth, in the process of machining the cylinder surface and precision holes, cubic boron nitride blade and reamer should be used to ensure the machining accuracy and surface flatness, and further improve the production efficiency. Fifth, it is necessary to reasonably control the cutting parameters of the machining center, so as to further optimize the cutting route, appropriately improve the cutting speed, ensure the uniform force on the top surface of the cylinder block in the process of cutting in and out, and realize the good control of the flatness of its front and rear ends. Sixth, after the large plate milling is completed, it is necessary to scrape the processing route around the top surface of the cylinder block again with the help of CNC control program and large brush addition to remove the burrs on the cylinder block. Seventh, control the workshop temperature at 20 ± 2 ℃ and the relative humidity between 40% – 60%. Figure 1 is the machining diagram of its machine tool.

3. Finishing process of cylinder hole

In the process of casting the cylinder block of automobile engine, the finishing of cylinder hole is also very important. Therefore, relevant enterprises and technicians must attach great importance to this processing technology and make it scientifically applied. Because the studied BMW engine cylinder block has very high cylinder hole accuracy requirements, in the specific processing, in order to realize the good guarantee of its cylinder hole processing quality, it is necessary to reasonably control the cylinder hole diameter tolerance before honing, and adjust the fine boring cylinder hole in the center of the cylinder hole to the preset size before honing. In order to ensure the surface quality of the cylinder hole, the internal cooling structure is selected for the fine boring cutter. In the specific processing, the product drawing shall be used as the basis to reserve the machining allowance after the fine boring of the cylinder hole diameter, and the reserved allowance shall be between 0.04-0.05mm for the subsequent honing treatment, and the roughness, cylindricity and perpendicularity shall be controlled according to the specific requirements to keep them consistent with the design drawings.

It is mainly processed by the vertical honing machine. In the specific processing, with the help of the promotion of the expansion mechanism, the oilstone in the honing head can realize radial feed, so as to gradually process the workpiece to the design size. The hinged honing sand bars can be embedded in the periphery of the honing head, 6 for rough honing and 9 for fine honing, and the length can be controlled between 1 / 3-2 / 3 of the length of the cylinder hole. In the honing process, the round-trip speed is maintained between 25-35m / min. the greater the acceleration in the reversing process, the smaller the transition area of the formed arc and the higher the quality of honing anilox. Fig. 2 is the honing machining diagram in the finishing of cylinder hole.