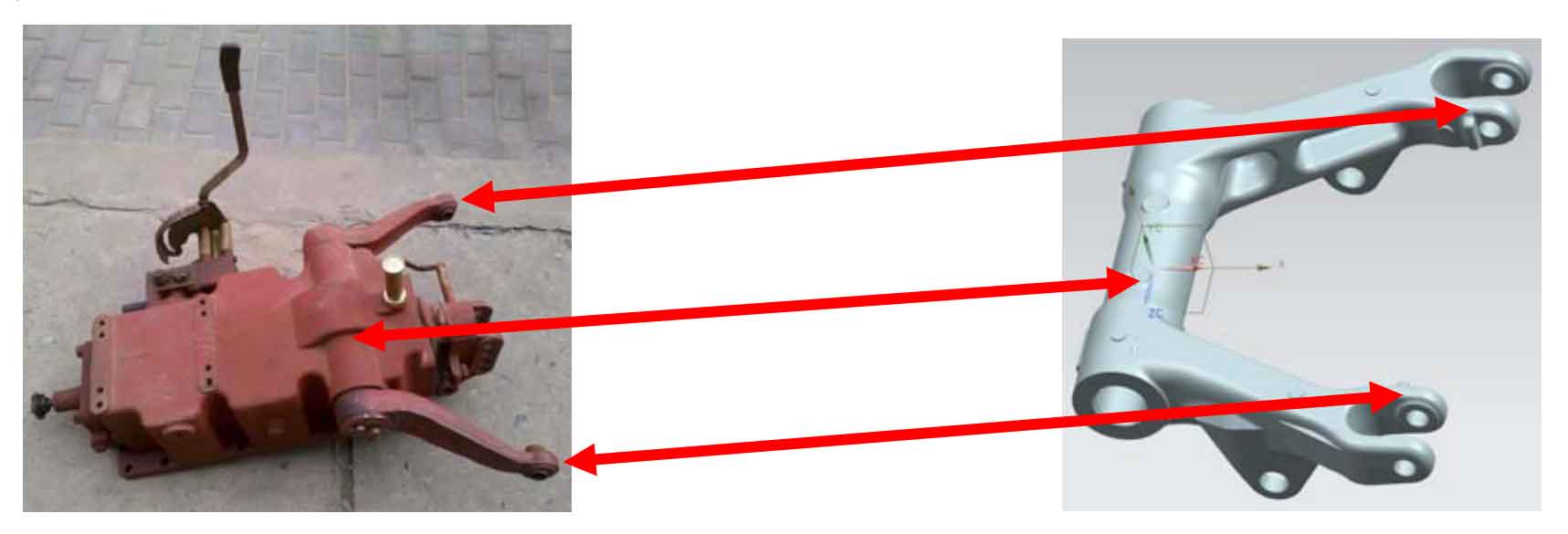

The nodular cast iron long fork is a lifting part on the hydraulic lifter of an agricultural tractor. It was originally divided into two lifting arms (i.e. “upper fork arm” and “lower fork arm” in the text) and three parts of a cylinder equipped with a lifting shaft between them (Fig. 1, left). Due to the lost foam casting process, it gives full play to the advantage of flexible product design freedom, Integrating the three parts into the single long fork (Fig. 1, right) can reduce the processing and assembly cost and improve the production efficiency. The part belongs to fork casting and has the characteristics of pipe fittings. The three-dimensional outline dimension is 375mm × 142mm × 552mm, the weight of a single piece is about 30kg, and the material is QT600-3. It belongs to Pearlite Nodular Cast iron.

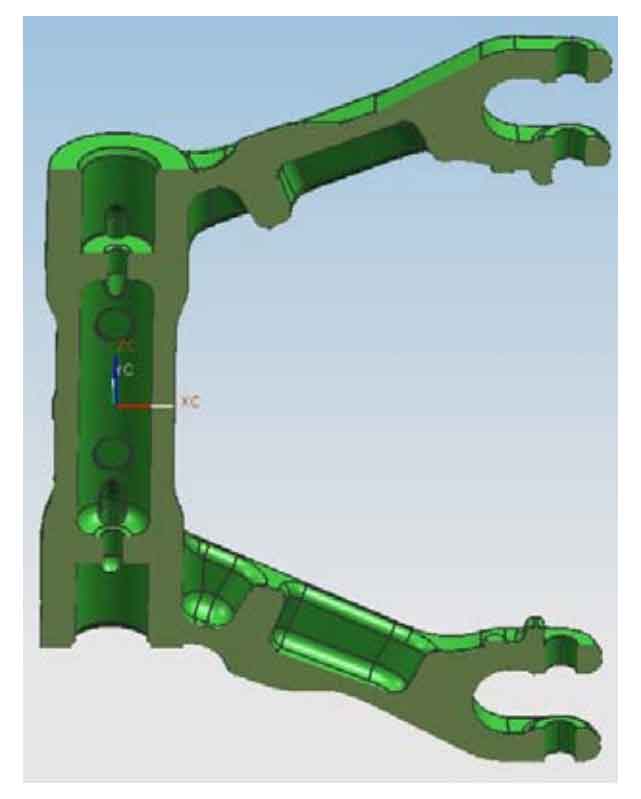

The structure of the long fork is complex, the surface is complex, and there are many bosses, pits, transition fillets and holes. The interior of the cylinder is a stepped through hole. The wall thickness transition of this part is large, the heat nodes are dispersed, and the cylinder wall in the middle part is relatively thin. The through hole on the fork arm is easy to be processed in the later stage, and it is not required to be cast when casting the blank.

The long fork is a load-bearing part with large stress and complex loading conditions. It is required that the internal structure of the long fork casting is dense and there shall be no serious hole defects. At the same time, the surface shall be free of sand holes, slag inclusion, wrinkle and other defects.