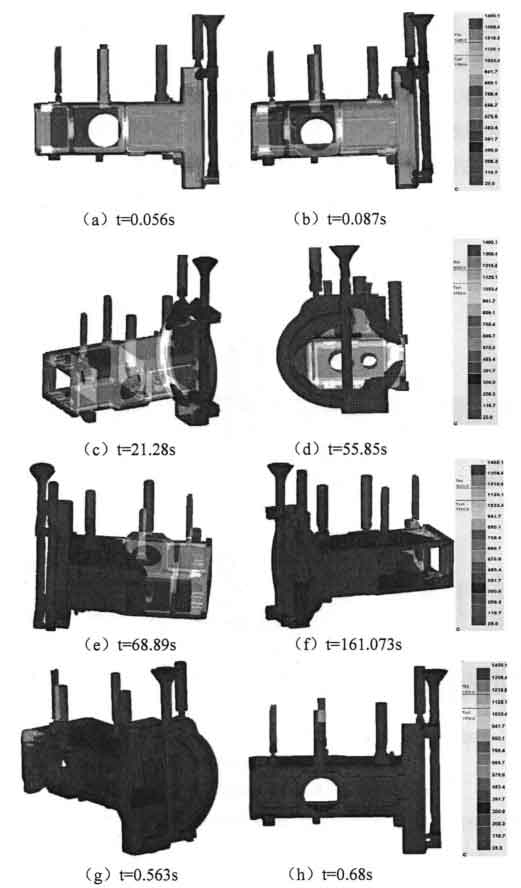

Figure 1 shows the filling process of the stepped gating system used in the sand casting of the tractor box. It can be found from Figure 1 that the stepped gating system used in the sand casting of the tractor box is quite different from the middle injection and top injection. In the initial stage of filling, the liquid metal first enters the inner sprue through the upper step and then enters the mold cavity, as shown in Figure 1 (a).

At 0.087s, the liquid metal flows into the lower step and enters the cavity through the lower inner sprue. Here, due to the large distance between the lower step and the gate, the liquid metal flows faster to the lower step, which may cause air entrainment and sand flushing; At 21.28s, it can be seen that the liquid metal flows into the cavity on both sides of the upper and lower steps. The liquid metal at the upper step flows downward along the inner wall of the circular boss and the rectangular boss under the action of gravity. The flow direction of the liquid metal at the connection of the circular boss and the rectangular boss and the fillet of the circular boss changes, which is easy to cause air entrainment. The liquid metal at the lower step flows from bottom to top under the action of pressure; It can be seen from Fig. 1 (d) that two streams of liquid metal converge in the middle of the circular boss; Then, the collected metal liquid will smoothly push towards the upper end of the sand casting of the tractor box along the flat plates on both sides at the same time, which is different from the middle injection type and top injection type, as shown in Figure 1 (E); Since there is a shaft mounting boss in front of the sand casting of the tractor box, there is a rectangular hole in the back, and the metal liquid required in the back is less than that in the front, the metal liquid in the back first reaches the top of the sand casting of the tractor box, and finally the metal liquid of the upper and lower plates converges at the riser at the upper end of the front, as shown in Figure 1 (g). It is possible to avoid the phenomenon of insufficient air filling at the bottom and top of the gating system, although the design speed of the step gating system is less than that of the top gating system.

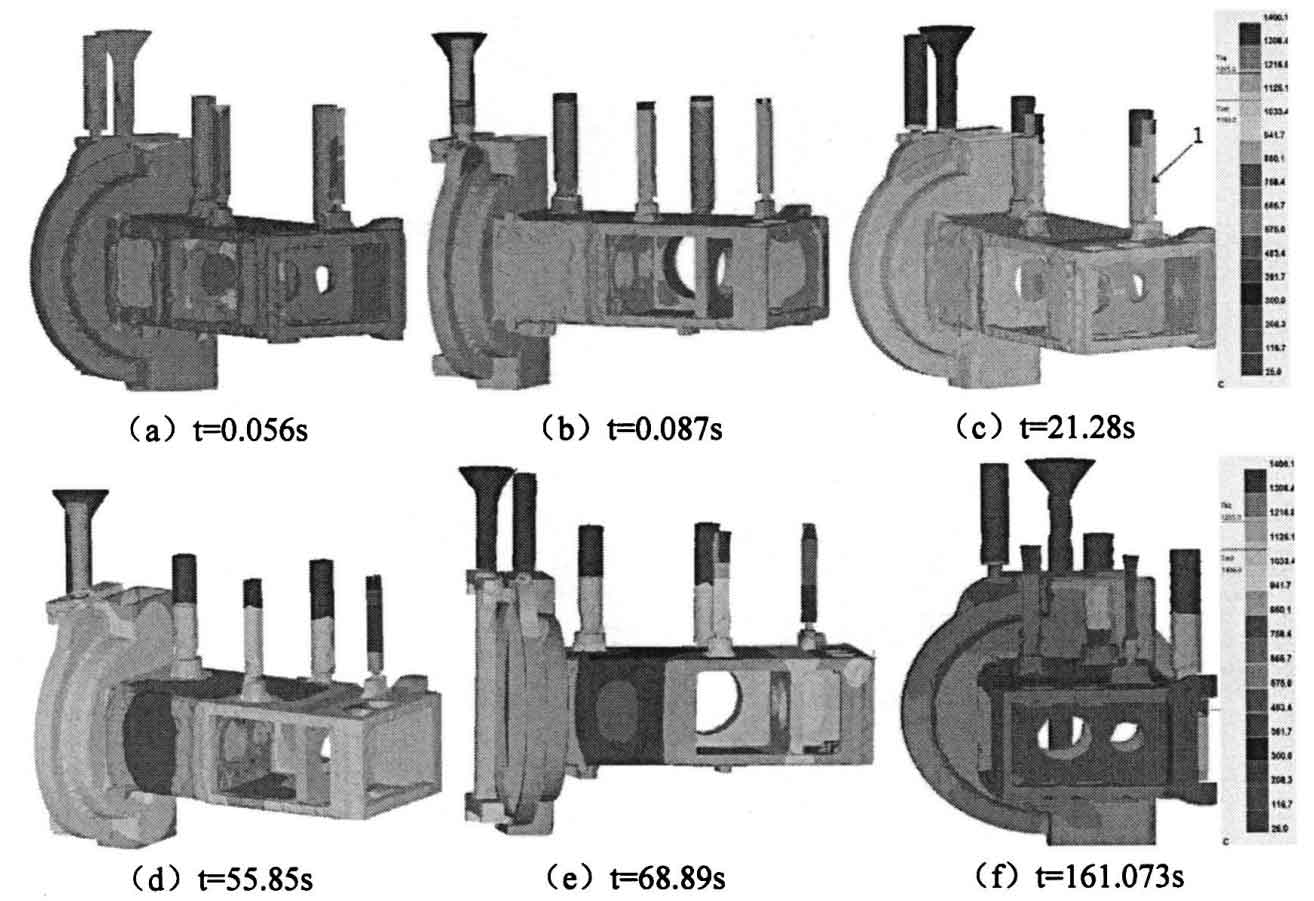

Figure 2 shows the changes of temperature field during solidification in the stepped sand casting scheme of tractor box at different times. After the filling of tractor box sand casting, the temperature began to drop. It can be seen from Figure 2 (a) that the temperature at the thin wall of the sand casting of the tractor box decreases rapidly. With the extension of time, each riser begins to play the role of feeding, among which the feeding of the riser on the circular boss is the most obvious, which is the same as that of the middle injection type and top injection type; At 21.28s, the metal liquid in the riser at the circular boss is completely used for feeding. The temperature of the riser indicated by the arrow in Figure 2 (c) has been falling the fastest during the whole solidification process. This is because in the above three schemes, the size of the riser is small and the heat dissipation is fast. After 21.28s, the temperature of the riser is below the solidus, resulting in insufficient feeding of the boss at the location; At 55.85s, the middle part of the sand casting of the tractor box solidifies rapidly, and the temperature here is higher than that of the flat plate, which is conducive to feeding; And the interface between the large plane on both sides and the boss is solidified in sequence to prevent shrinkage and other defects here; At 68.89s, the feeding capacity of the riser at the circular boss is insufficient, but at this time, the liquid metal temperature at the inner sprue is high, so feeding can be carried out, so defects at the circular boss can be prevented; As in the case of middle injection type and top injection type, the last solidification part is the support plate and shaft mounting hole on the upper side of the box.

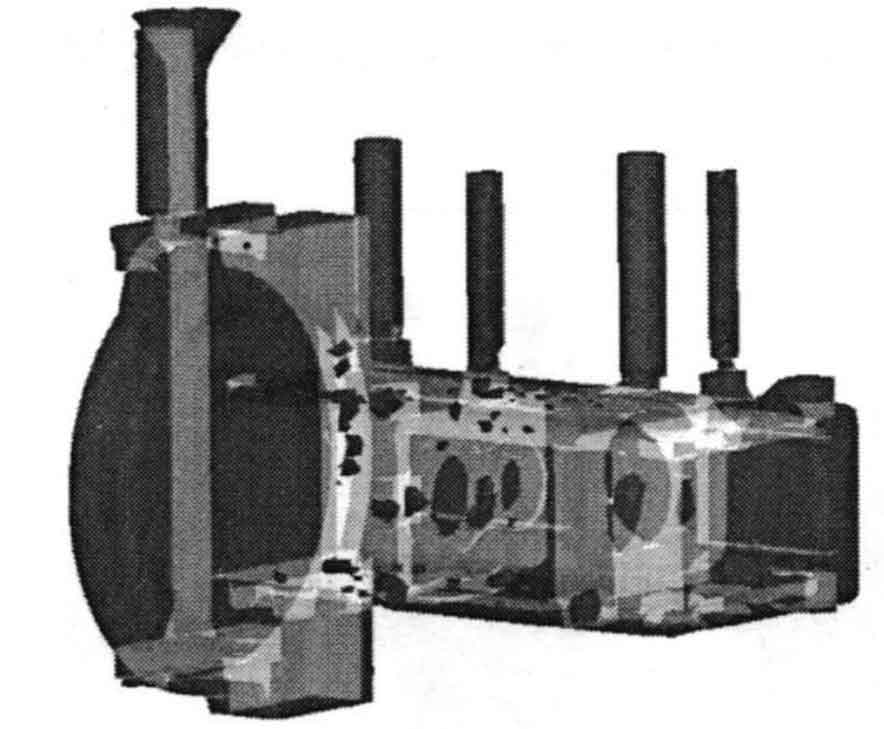

In the whole process of mold filling and solidification, the mold filling is relatively stable without insufficient pouring. During solidification, the riser at the circular boss and the riser indicated by the arrow in Figure 2 (c) are insufficient. As shown in Figure 3, the distribution of shrinkage porosity and shrinkage cavity of the stepped scheme of sand casting of tractor box; As shown in Figure 3, the defects mainly appear on the flat plates on both sides and the support plate below the interior. Because there is uneven wall thickness at the support plate below the interior, this scheme still needs to be improved.