The riser is to compensate for the possible shrinkage during the formation of sand castings, prevent the shrinkage cavity and porosity of sand castings, and play the role of exhaust, slag collection and guiding mold filling. The solidification time of riser depends on the ratio of its volume to heat transfer surface area, referred to as modulus.

The riser is designed by modulus method. According to chvorinov formula, the solidification time TC and tr of sand casting and riser are respectively:

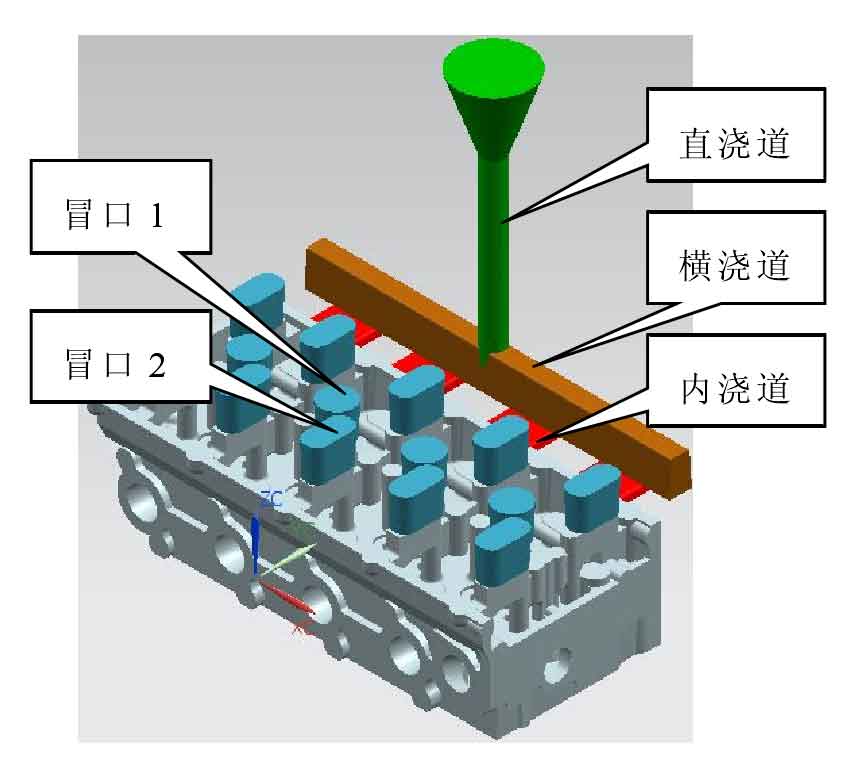

According to feeding conditions, the solidification time of riser shall be greater than or equal to the solidification time of sand casting, tr ≥ TC; Where MC and MR are the modulus of sand casting and riser respectively, and KC and Kr are the solidification coefficient of sand casting and riser respectively. According to the structural characteristics of sand casting feeding, the standard waist top open riser is selected and located in the upper box. Two kinds of risers are preset according to the feeding position, shape and volume. To sum up: the three-dimensional model of the designed pouring and riser system is shown in the figure.

The whole set of mold adopts sand casting. During the pouring process, a large amount of gas will be produced by sand mold gas, resin volatilization and impurity burning. These gases must be discharged from the mold cavity in time, otherwise it will affect the molding of sand castings. Therefore, without affecting the contour of sand castings, a large number of exhaust holes are set on the sand core and mold surface, and exhaust plugs are installed to prevent the outflow of liquid metal.

Because of the complexity of castings and the high requirements of sand casting process, the process yield of products can be guaranteed. Therefore, the machining grade H is selected, the machining allowance is set to 4mm, and the wall thickness of the connecting riser on the upper surface of the cylinder head is large, which is set to 5mm; The dimensional accuracy of sand casting cylinder head is high, and the scale of sand casting directly affects whether the size of sand casting is qualified. According to experience, the overall shrinkage of sand casting is selected as 1%.