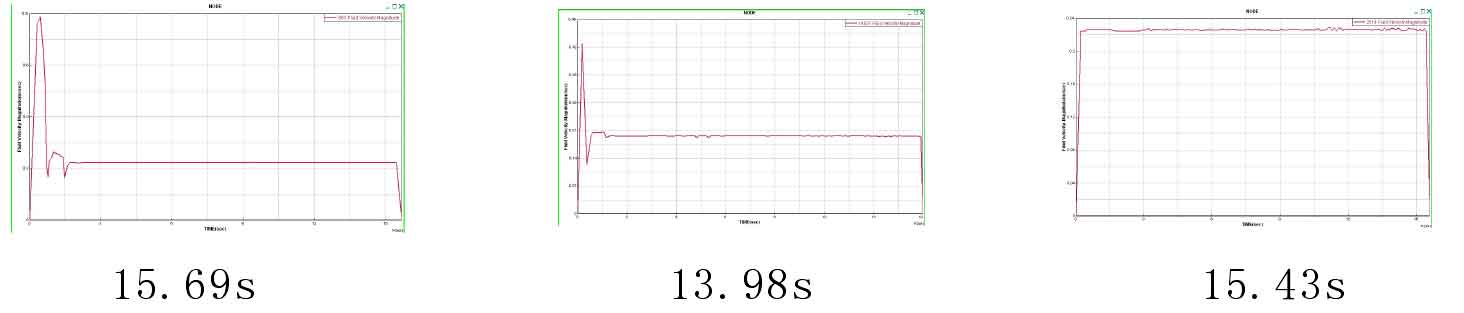

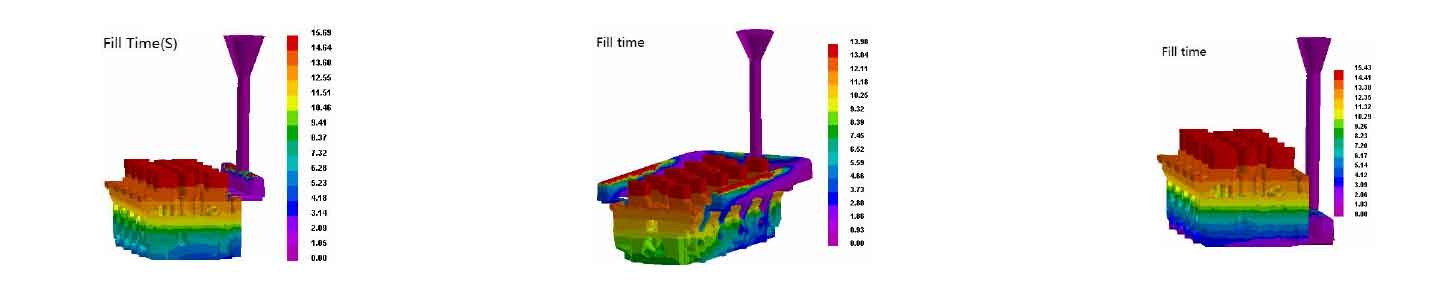

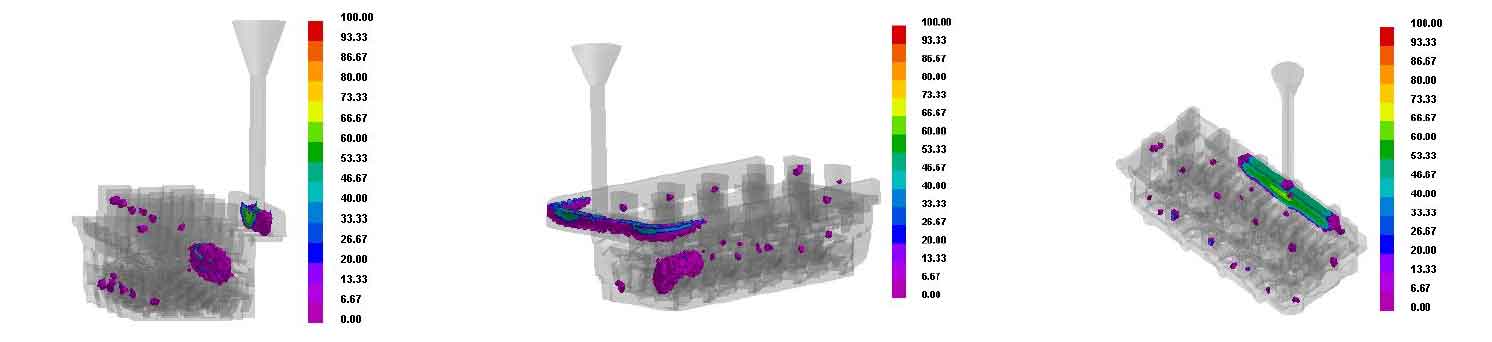

According to the analysis of sand casting process, the design of three gating systems is put forward. The influence of the design of different gating systems on the sand casting results of cylinder head is shown in the figure.

The bottom injection method has the best stability and performance, and scheme 3 is ideal. The first scheme and the second scheme will produce obvious centralized shrinkage, the third scheme has only decentralized shrinkage, and the third scheme is better than the other two.

The casting CAE software ProCAST is used to optimize and analyze the three gating systems without improving the riser process. Through the analysis of the temperature field of sand casting in the process of mold filling and solidification, the calculation of solid rate, and the display of the position and size of shrinkage porosity and shrinkage cavity, the possible sand casting defects of each gating system are compared, and it is found that the third scheme is the best. In the third scheme, the pouring speed should be 0.22m/s.