Bismuth can significantly increase the number of graphite spheres. When the number of graphite balls in nodular cast iron increases, the diameter and spacing of graphite balls decrease accordingly. During solidification, this can accelerate the diffusion rate of carbon in the matrix and promote the formation of ferrite. In addition, the increase of the number of graphite balls in nodular cast iron also avoids the segregation of graphite balls to a certain extent and makes them evenly distributed, which is beneficial to improve the mechanical properties.

The table shows the effect of 0.006% bismuth on the mechanical properties of nodular cast iron.

| Number | Chemical composition | Chemical composition | As cast | As cast | As cast | As cast | Heat treatment | Heat treatment | Heat treatment | Heat treatment |

| – | Si/% | Bi/% | Tensile strength /MPa | Elongation /% | Impact toughness /J | Hardness /HB | Tensile strength /MPa | Elongation /% | Impact toughness /J | Hardness /HB |

| A4 | 1.95 | — | 422 | 11.5 | 12.6 | 149 | 380 | 23 | 15.8 | 143 |

| A7 | 2.07 | 0.006 | 390 | 24.5 | 15.2 | 147 | 379 | 25.5 | 16.9 | 139 |

It can be seen from the table that when 0.006% bismuth is added, the tensile strength of nodular cast iron decreases, the elongation increases, the low-temperature impact toughness increases obviously, and the hardness is basically stable. After heat treatment, the tensile strength, hardness and low-temperature impact toughness are basically the same, and the elongation is higher.

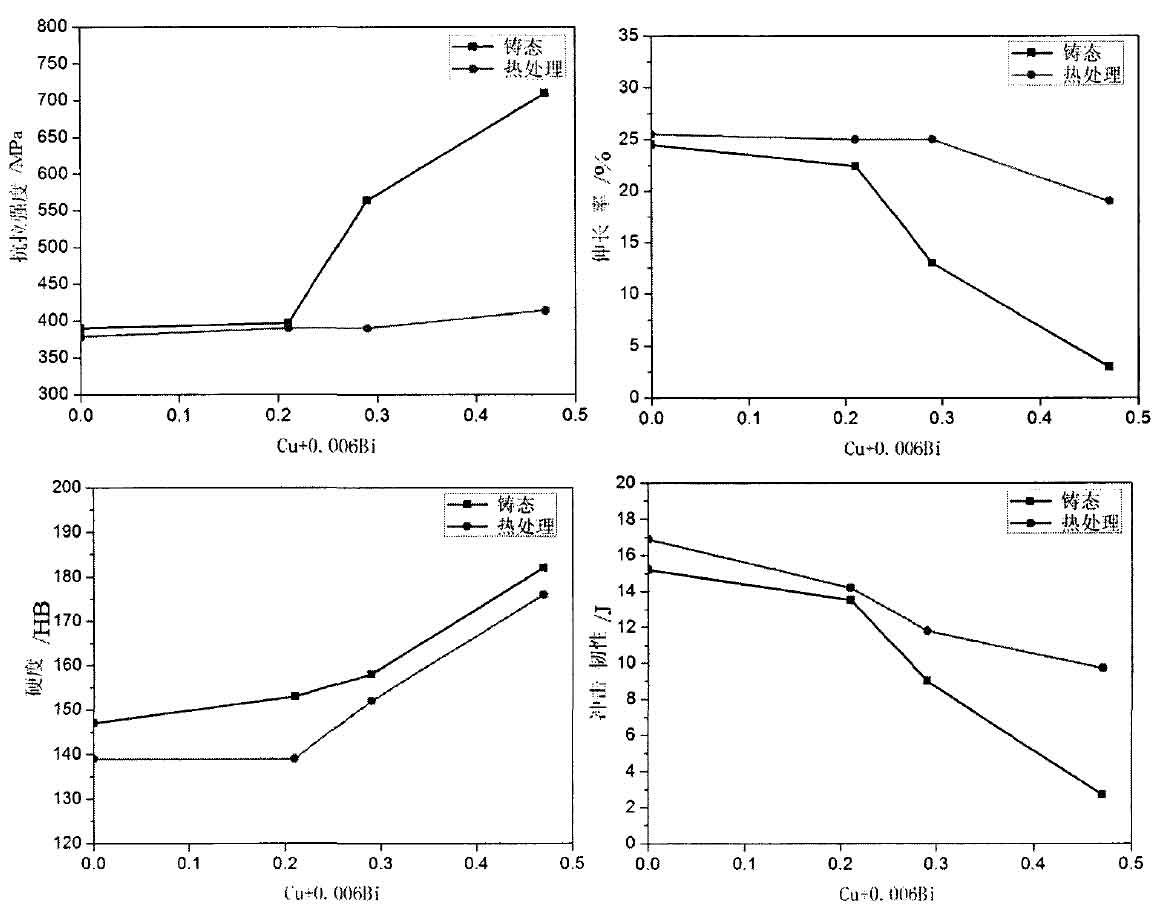

The figure shows the effect of different content of copper and 0.006% bismuth on the mechanical properties of nodular cast iron.

It can be seen from the figure that on the premise of containing 0.006% bismuth, the added copper slightly increases the tensile strength and hardness, and decreases the elongation and low-temperature impact toughness. If the added amount of copper increases again, it will obviously increase the tensile strength and hardness, and decrease the elongation and low-temperature impact toughness. However, through heat treatment, the tensile strength of nodular cast iron is obviously stable at 400MPa, the elongation and low-temperature impact toughness are improved, and the growth rate of hardness becomes slower. When WCu = 0.3% and WBI = 0.006%, the low-temperature impact toughness of nodular cast iron after heat treatment can also reach the level of 12j, which has better comprehensive properties.

In actual production, the performance of nodular cast iron wind power accessories not only requires low-temperature impact toughness, but also requires tensile strength, elongation and hardness. At this time, good comprehensive performance has become an inevitable requirement. Single chain addition only strengthens the low-temperature impact toughness, and can not realize the simultaneous strengthening of multiple performance indexes. In order to achieve common strengthening, copper and copper can be used together to achieve high comprehensive performance.