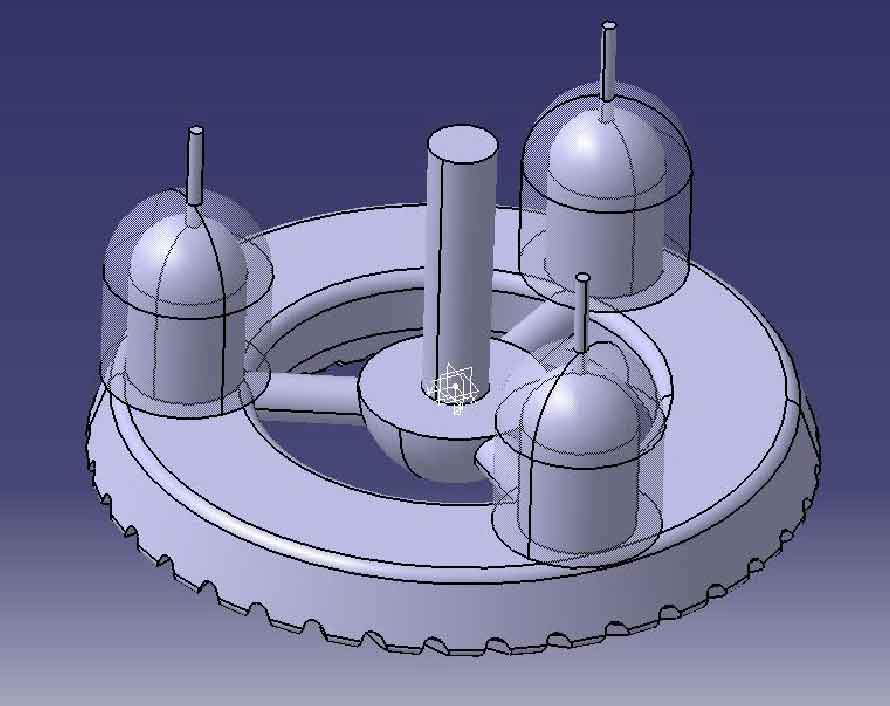

Generally speaking, due to the influence of gravity, there are more sand casting defects on the upper surface of steel castings than on the lower surface. The steel casting of driven spiral bevel gear is a thin-walled ring part and has high requirements for the forming quality of the tooth shape part, so put the tooth shape surface below. In order to facilitate the mold lifting of sand casting, combined with the structural characteristics of spiral bevel gear steel casting, the maximum section of gear blank, that is, the edge of large end tooth shape, is set as the parting surface.

The total volume of sand castings and risers is about 0.6L, which belongs to small steel castings, so subcontracting pouring is used.

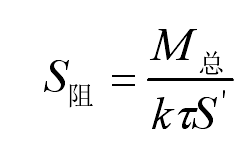

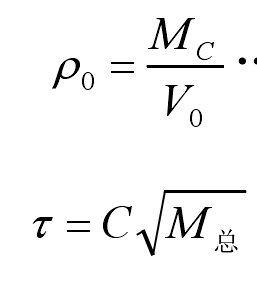

The cross-sectional area of closed open gating system decreases first and then increases; The flow blocking section is closed before and then open, which combines the advantages of open gating system and closed gating system. It not only improves the slag skimming and slag retaining capacity of the gating system, but also reduces the metal flow rate at the inner sprue to ensure the stable mold filling capacity of liquid metal. Therefore, closed open gating system is selected. Considering the structural characteristics of the central top injection scheme, the choke section is set at the lower end of the sprue, that is, s straight up > s straight down = s resistance > s. The calculation formula of choke cross-sectional area is as follows:

Where,

M – total mass of molten metal of riser and sand casting (kg);

S – area of choke section (cm2);

S’ – liquid metal flow coefficient of sand casting, carbon steel 1;

K – pouring specific speed.

Pouring specific speed and pouring time τ Relative density of sand castings ρ 0, the formula can be listed as follows:

Where,

ρ 0 – relative density of sand casting (kg / dm3);

MC – mass of sand casting (kg);

V0 – contour volume of sand casting (DM3), that is, the product of the maximum dimensions in three directions of steel casting;

C – pouring time coefficient;

τ — Pouring time (s).

The steel casting of driven spiral bevel gear has a mass of about 3.9kg and belongs to a small ring. Consult the sand casting manual and select the minimum sand consumption as follows: the distance between the steel casting mold and the side of the sand box shall be at least 20mm; The pattern shall be at least 50mm from the bottom of the sand box; The distance from the top of the riser to the box belt shall be at least 40mm.