When the original sand casting process produces the shell casting, the molding, core making, lower core box closing, pouring, sand dropping and other processes are basically produced according to the normal rhythm. However, due to the poor quality of the steel castings of the shell casting and the high scrap rate, the workload in the blank welding repair process and machining process increases greatly, such as repeated welding repair, multiple flaw detection and sand inclusion, resulting in the cutting of machining process and the out of tolerance of product processing size.

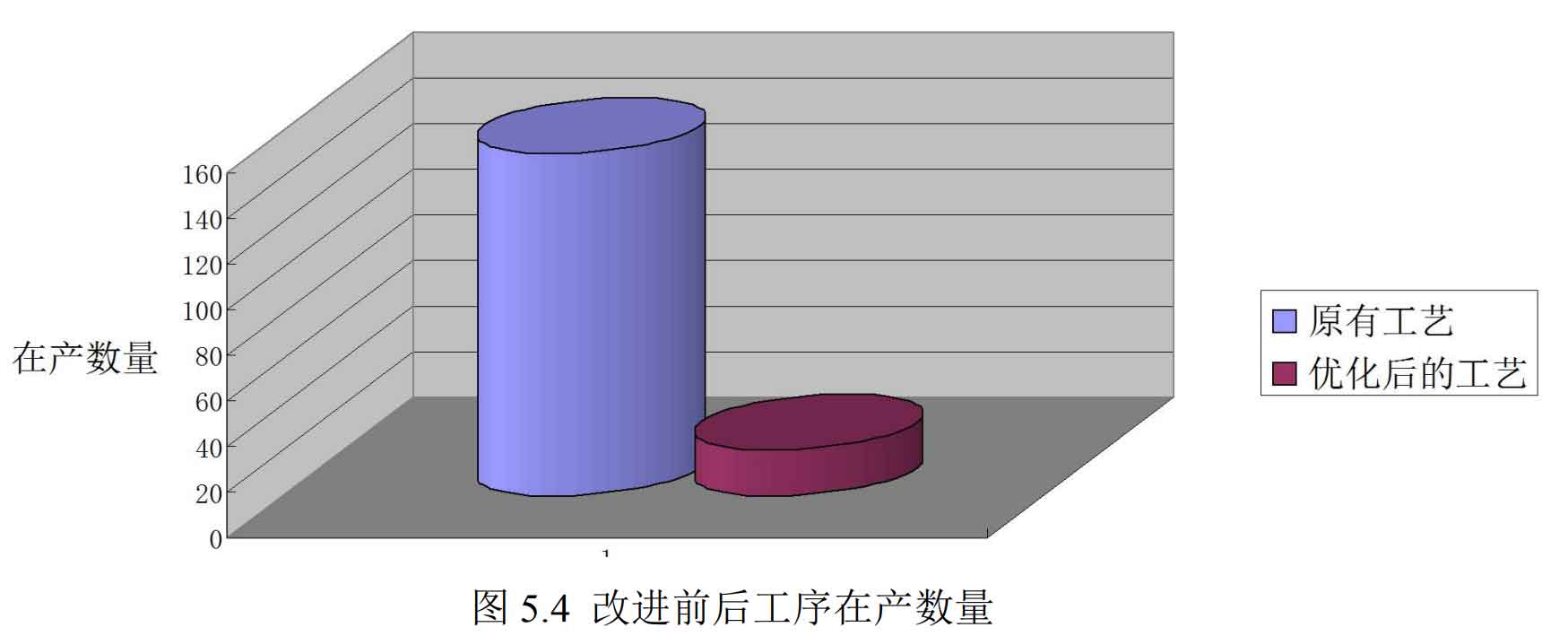

The production rhythm of the post sand casting process lags far behind that of the previous process, resulting in the backlog of shell steel castings, insufficient space, occupation of funds, increased repair costs and labor costs. After the implementation of the new sand casting process, due to the good quality of the shell steel castings and the low scrap rate, the production rhythm and process capacity of each sand casting process are relatively matched. Basically, only a small amount of steel castings in the shell are overstocked in each sand casting process, the site is spacious, the working environment is improved, and the production efficiency is more than twice that of the original. The number of steel castings in the shell casting before and after improvement is shown in the figure.

Before the improvement of product quality, only 160 finished steel castings of motor housing can be completed at most in a month, and 100% on-time delivery can not be guaranteed. As a result, many orders were not accepted, which seriously affected the operation and development of the company. After the optimization of sand casting process, due to the significant improvement of product quality, the production capacity of 450 pieces per month can be reached, and the quality and quantity can be supplied to customers. There is no delay in delivery from June 2020 to December 2020. The punctuality of delivery date and the improvement of product quality have also laid a solid foundation for the company to win the market of motor shell steel castings.