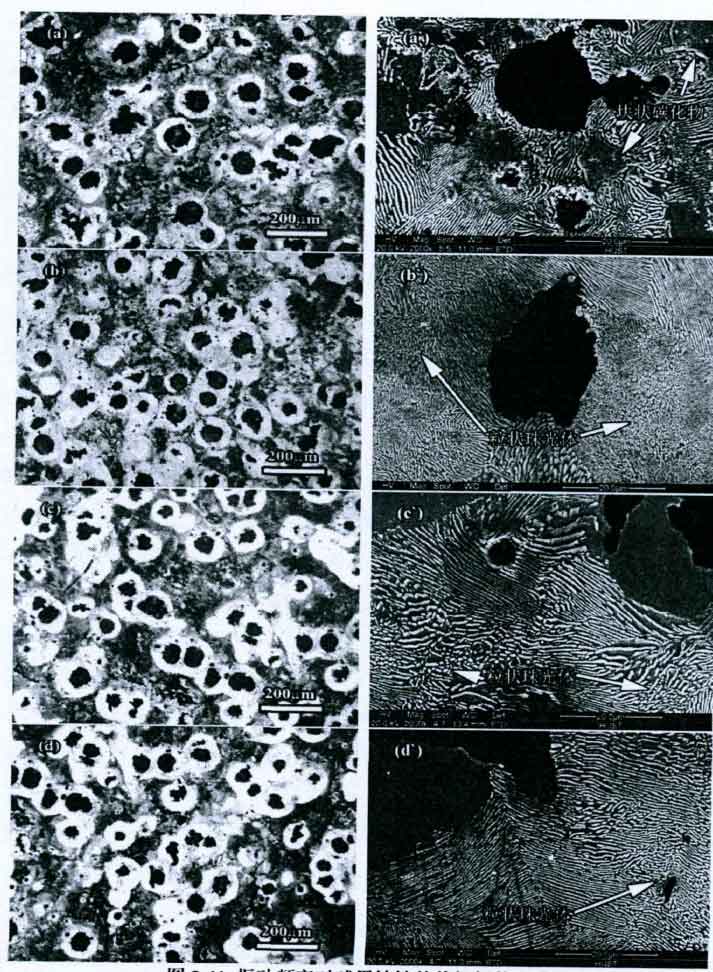

Fig. 1 is the matrix structure diagram of ductile iron in lost foam casting under different vibration frequencies with amplitude of. Among them, figure 1 (a) and (a’, (b) and (B’, (c) and (C’, (d) and (d’) are the matrix structure diagrams of nodular cast iron prepared at the vibration frequencies of 0, 35, 50 and 100Hz, respectively.

It can be seen from Figure 1 (a) – (d) that the matrix structure of nodular cast iron is graphite, pearlite and ferrite. The content of ferrite in the vibration lost foam casting nodular cast iron is higher than that in the lost foam casting nodular cast iron without vibration, and the content of pearlite is less than that in the lost foam casting nodular cast iron without vibration. In addition, it can be seen from the scanning photos that there are a certain amount of massive carbides in the EPC nodular cast iron without vibration, but no massive carbides are found in the EPC nodular cast iron with vibration. Comparing the pearlite flake spacing of nodular cast iron prepared by different processes, it can be seen that the nodular cast iron prepared at the vibration frequency of 35Hz is the smallest, and there are granular carbides in the pearlite; When the vibration frequency is 50Hz, the pearlite flake spacing of the nodular cast iron increases, but there is still a certain amount of granular pearlite in the nodular cast iron; When the vibration frequency is further increased to 100Hz, the plate spacing of pearlite is further reduced.

The pearlite structure in nodular cast iron is the product of eutectoid transformation in the solidification process of cast iron. The pearlite structure is formed by the eutectoid transformation of parent austenite. The transformation from austenite structure to pearlite structure is a typical diffusion type transformation, that is, the solid-solid transformation from one solid phase to the other two solid phases. It can be seen from Fig. 1 that granular pearlite exists in the vibration lost foam casting nodular cast iron, but no granular pearlite is observed in the lost foam casting nodular cast iron without vibration. In addition, there are massive carbides in the EPC nodular cast iron without vibration, as shown by the arrow in Figure 1 (A’), while no massive carbides are observed in the EPC nodular cast iron with vibration. It is generally believed that vibration has a significant effect on the solidification structure of metal, and has little effect on the structure in solid phase transformation. The results show that vibration not only plays an important role in the solidification structure of EPC nodular cast iron, but also has a great influence on the eutectoid transformation products in EPC nodular cast iron, and the underlying mechanism needs to be further studied.

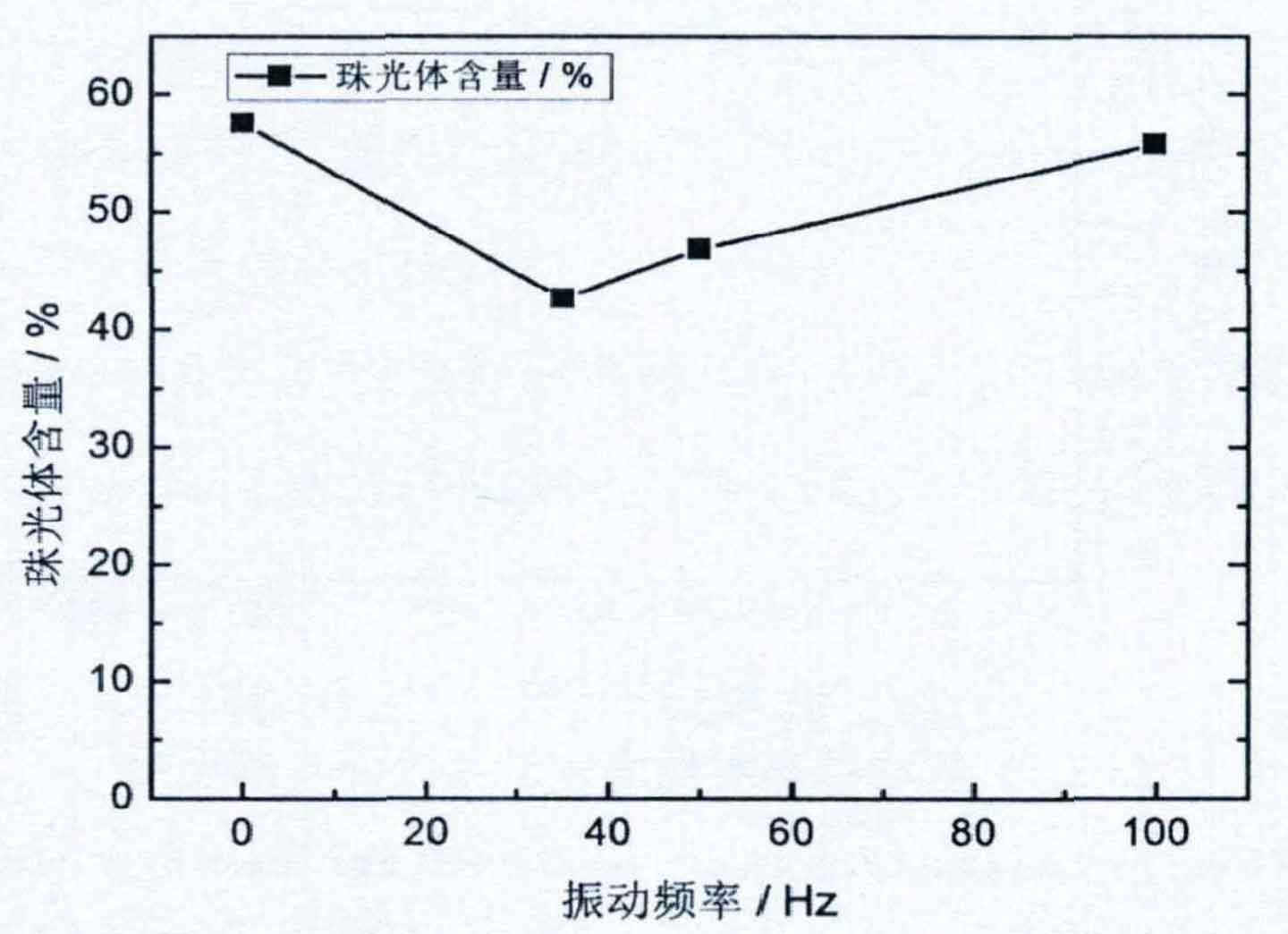

In addition, the vibration frequency affects the amount of austenite generated during solidification, which has an important impact on the pearlite content generated during eutectoid reaction. The results of statistical analysis of the pearlite content in Figure 1 by using the software show that the pearlite content is the highest in the EPC nodular cast iron without vibration, which is about 57.6%. When vibration is applied to the EPC nodular cast iron, The pearlite content in nodular cast iron decreases, and when the vibration frequency is 35Hz, the pearlite content is the lowest. If the vibration frequency is further increased, the pearlite content increases, as shown in Figure 2.