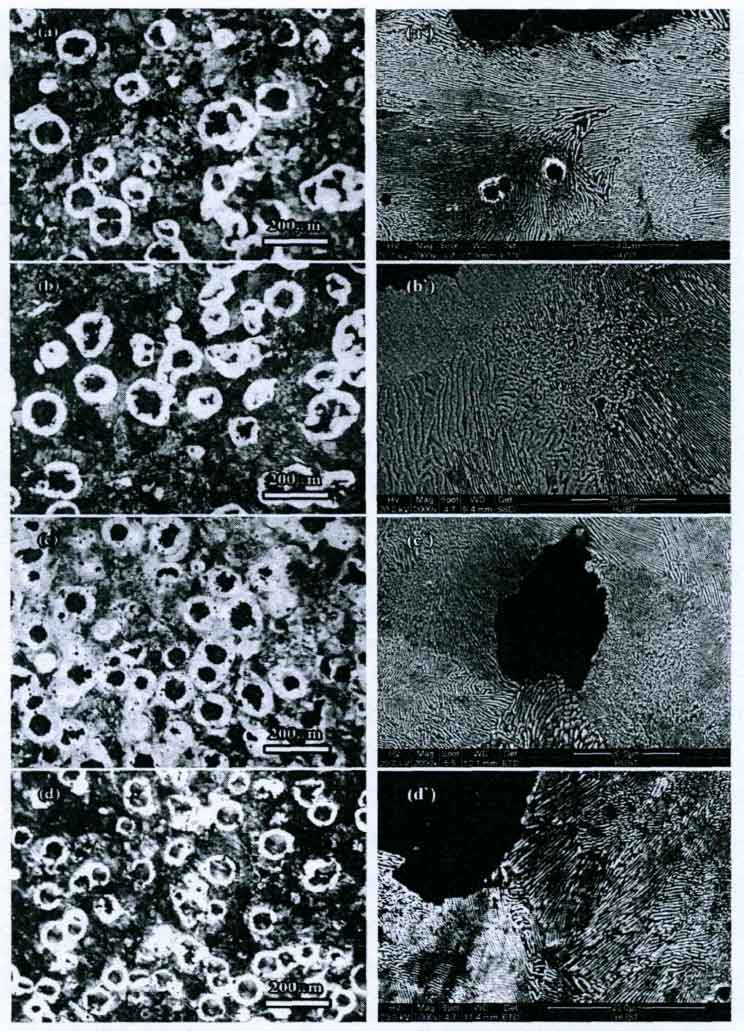

Figure 1 shows the matrix structure of nodular cast iron prepared under different amplitudes. Among them, figure 1 (a) and (a’0, (b) and (b’), (c) and (c’), (d’) and (d’) are the matrix structure diagrams of nodular cast iron prepared at amplitudes of 0.75, 2, 3 and 4mm respectively.

It can be seen from Figure 1 (a) – (d) that the matrix structure of nodular cast iron is graphite, pearlite and ferrite. The content of pearlite in nodular cast iron prepared under the condition of amplitude is higher, while the content of pearlite in nodular cast iron prepared under the condition of amplitude is 3mm is the least. In addition, it can be seen from the scanned photos that when the amplitude is

The pearlite flake spacing of nodular cast iron prepared under the conditions of 0.75mm and 2mm is larger. Comparing the nodular cast iron prepared by the two processes, it can be seen that the pearlite flake spacing of nodular cast iron prepared under the amplitude of 0.75mm is larger than that of nodular cast iron prepared under the amplitude of 2mm; With the increase of amplitude, the lamellar spacing of pearlite decreases, especially that of nodular cast iron prepared at the amplitude of 4mm. In addition, it can be seen from Figure 1 (C’) that the increase of amplitude not only reduces the pearlite sheet spacing, but also disperses and distributes granular carbides in the pearlite structure. It can be seen that increasing the amplitude of vibration lost foam casting while keeping the vibration frequency unchanged is conducive to reducing the pearlite sheet spacing in nodular cast iron.

The pearlite flake spacing decreases with the increase of amplitude. The main reason is that after the amplitude increases, the force introduced by vibration into the melt increases, which speeds up the heat transfer in the solidification process of the metal melt. The solidification speed of the metal chip culture accelerates, reduces the diffusion ability of iron and carbon atoms in the metal, reduces the diffusion distance, and finally produces pearlite with small flake spacing.

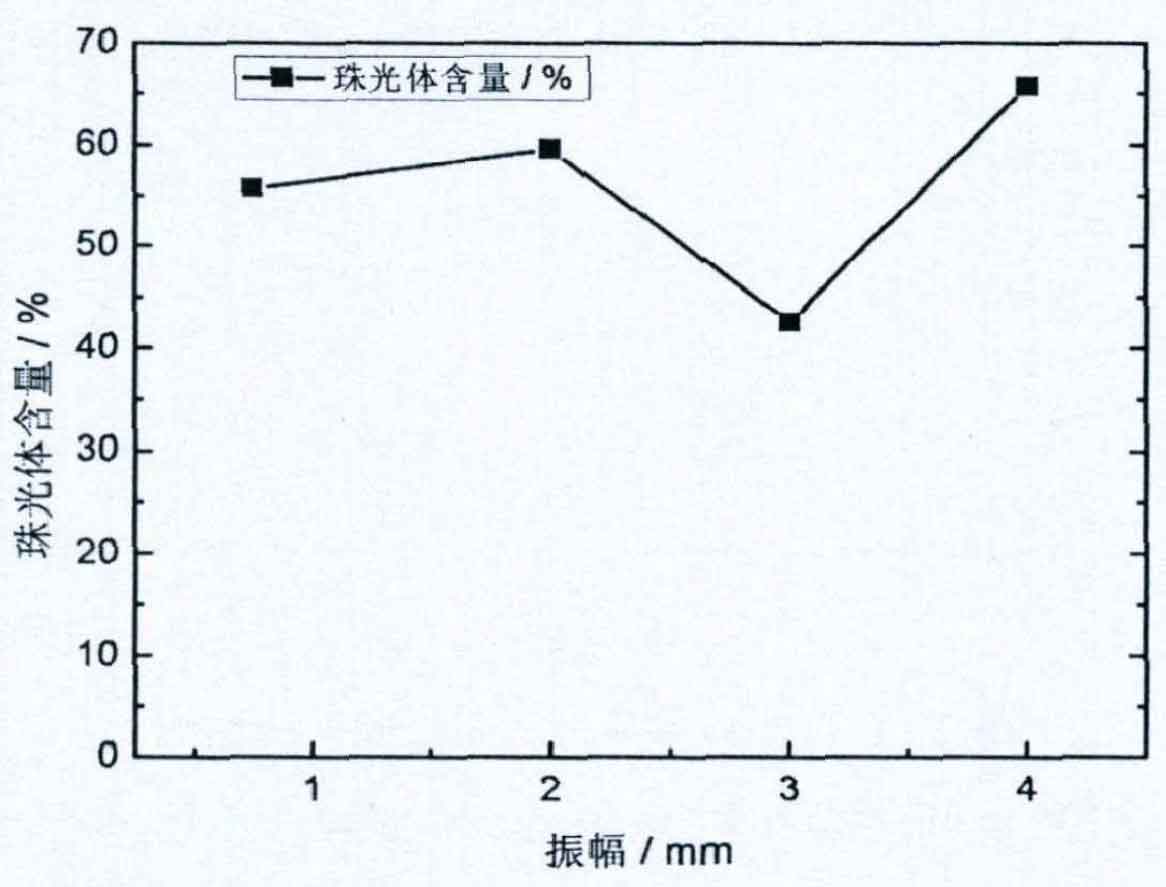

The software is used to statistically analyze the pearlite content of nodular cast iron prepared under different amplitudes. The results are shown in Figure 2. It can be seen from Figure 2 that with the increase of amplitude, the change of pearlite content shows a broken line trend. When the amplitude is 4mm, the content of pearlite is more.