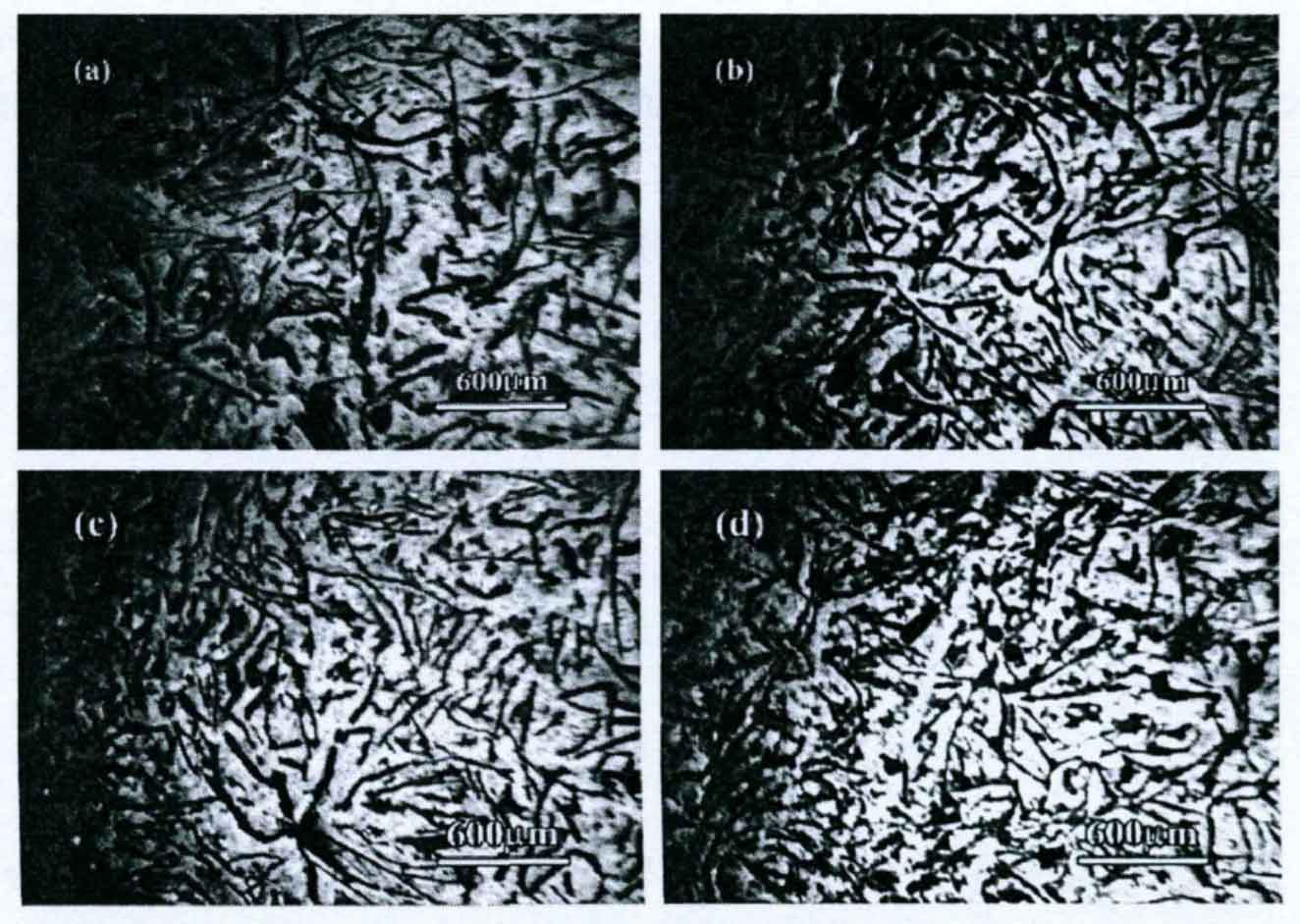

The figure shows the austenite morphology of gray cast iron prepared under different vibration frequencies. Figures (a) – (d) show the austenite morphology of gray cast iron prepared at vibration frequencies of 0, 35, 50 and 100Hz respectively.

It can be seen from the figure that in the gray cast iron without vibration, the primary dendrite arm of primary austenite is relatively developed, and the secondary dendrite structure is relatively coarse. When the vibration frequency increases to 35Hz, the size of primary austenite dendrites decreases, the primary dendrites are undeveloped, and the secondary dendrites are fine. When the vibration frequency increases above 50Hz, the primary dendrite of austenite is not developed, but the grain of secondary dendrite is coarse.

Mechanical vibration during solidification of gray cast iron can affect nucleation and growth of primary austenite. Mechanical vibration causes cavitation effect in the gray cast iron solution, forming a large number of holes. When the holes collapse, the surrounding metal bodies enter the holes and generate greater pressure. The increase of pressure will increase the temperature of the gray cast iron. In addition, the volume of gray cast iron decreases during solidification. According to the Clapeyron equation, the melting point of gray cast iron increases with the increase of pressure change value. Mechanical vibration can increase the temperature of the alloy, that is, the average temperature of the alloy liquidus. Under the condition that the metal solidification temperature remains unchanged, it is equivalent to improving the solidification undercooling of the alloy, thus refining the primary austenite in the alloy.

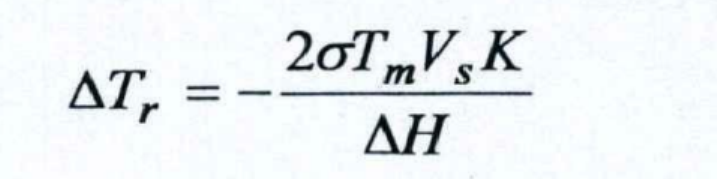

In addition, the primary austenite of gray cast iron precipitates in dendrite morphology, and the surface curvature on the dendrites is very different. According to the thermodynamic formula, the change of equilibrium temperature due to different curvature can be calculated Δ Tr: