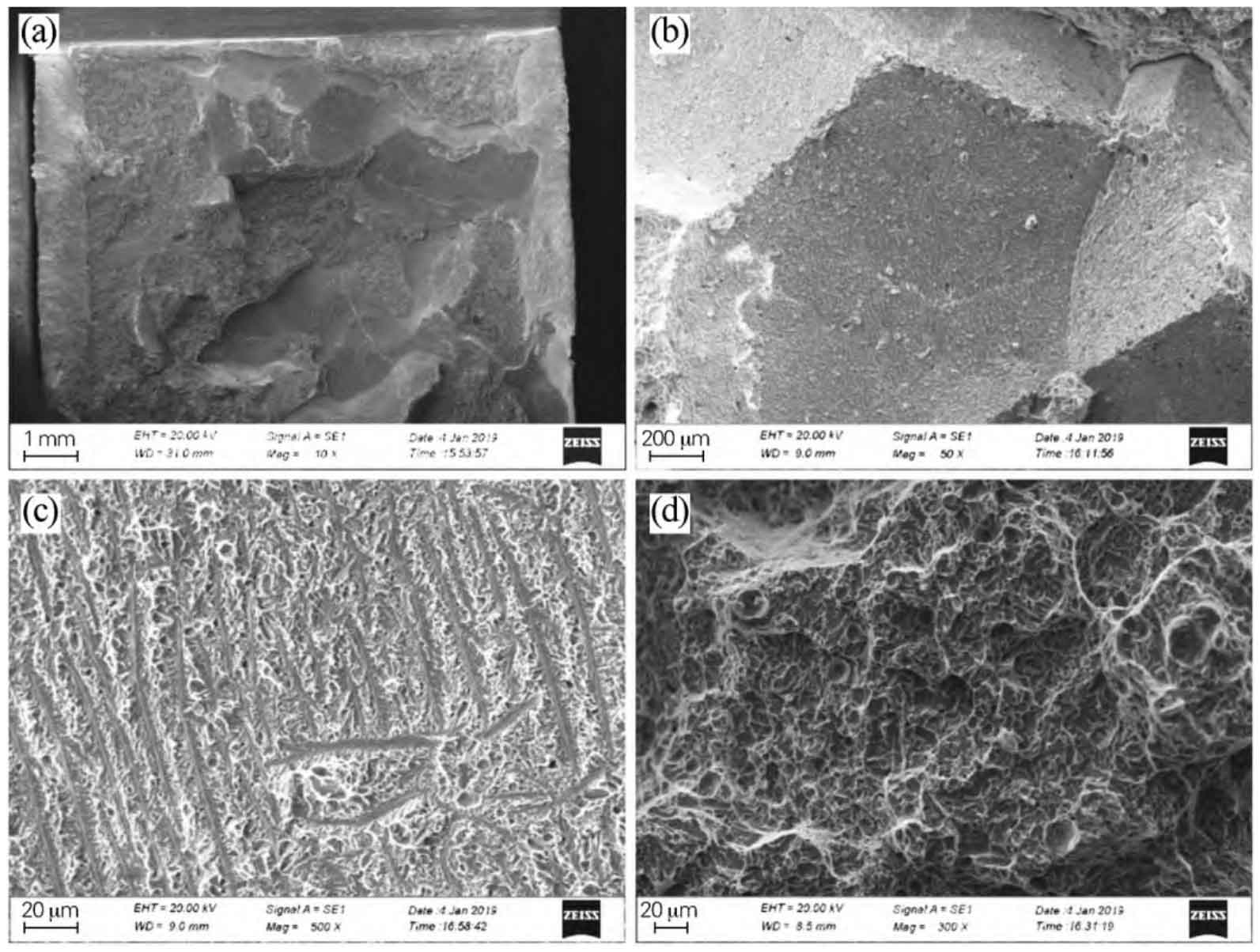

1. Fractograph

The fracture morphology of impact sample was observed by Zeiss evo15 scanning electron microscope. The fracture morphology of steel casting is shown in Figure 1. It can be seen from Figure 1 that the macro fracture morphology of the steel casting is relatively abnormal, and there are many small planes on the fracture of the steel casting, which belongs to the intergranular fracture with obvious SEM fracture morphology of the normalized test steel in Figure 1. Under the scanning electron microscope, there are many stripes distributed on the small plane of the fracture surface of the steel casting, which are characterized by cleavage and quasi cleavage; Dimple morphology was observed at the edges of both sides.

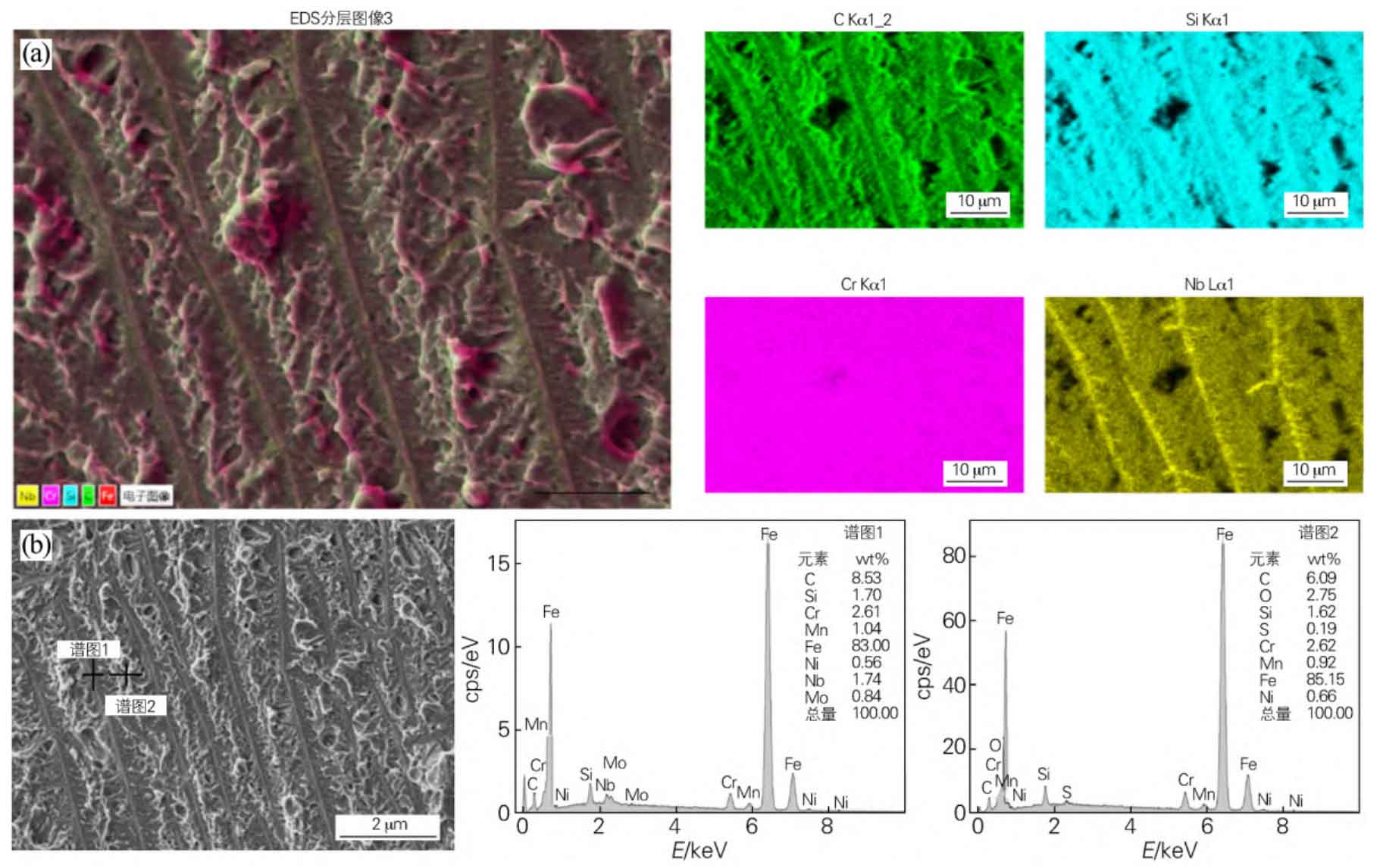

2. Energy spectrum scanning and component analysis

X-max50 energy spectrometer is used to analyze the micro zone composition at the stripe on the small plane of the fracture of the steel casting. The results are shown in Figure 2. It can be seen from Figure 2 that the scanning results of the cross-section of the steel casting show that the Nb distribution is uneven and there is segregation. The quantitative analysis results show that the Nb content at the stripes is 1.74%. The Nb content between the stripes is too low to be detected, and the Nb content at the stripes is higher than that at the surrounding non stripes.

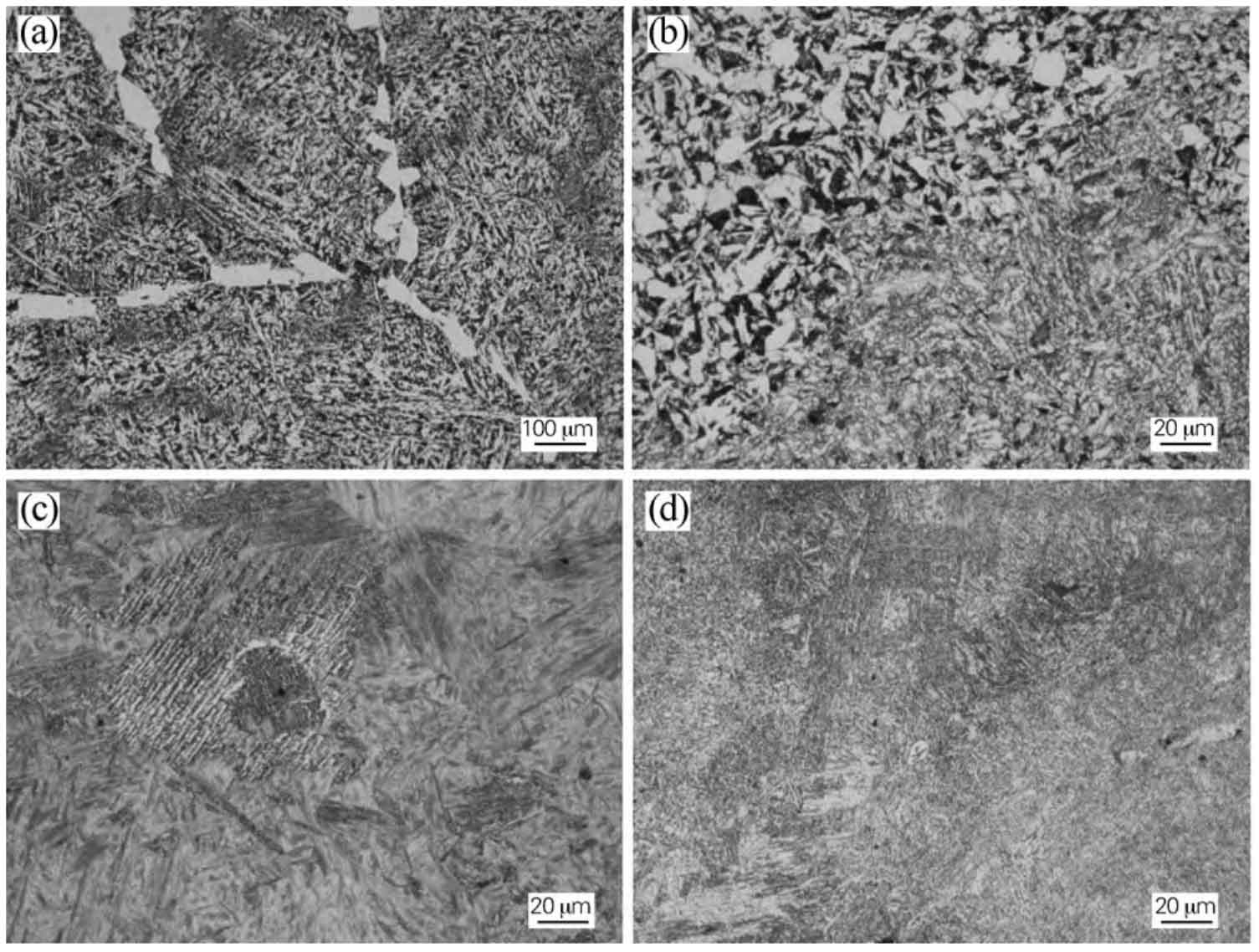

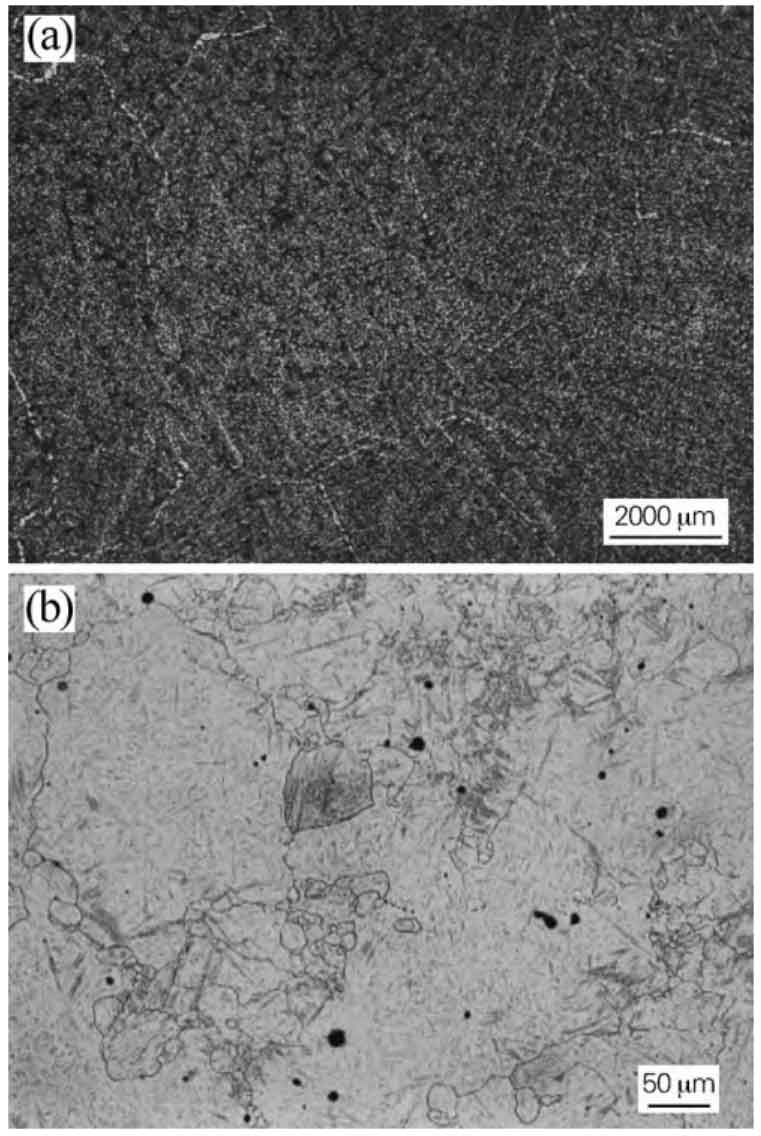

3. Microstructure

Take the as cast, normalized, Quenched and tempered test pieces of the same batch and prepare samples at the same position. Use 4% nitric acid alcohol solution for erosion, and then use Zeiss imager.m2m optical microscope for microstructure inspection. The results are shown in Figure 3. As cast microstructure is strip and block ferrite distributed along grain boundary, and acicular ferrite + pearlite is in the crystal; The normalized state is ferrite + pearlite + granular bainite; The quenching state is martensite + granular bainite; The quenched and tempered state is tempered sorbite. The grain size of as cast and quenched structures is tested, and the results are shown in Figure 4. The grain size grade of as cast structure is inferior to grade 00 in GB /t 6394-2017 method for determination of average grain size of metals. The grain size is close to the small plane size on the fracture surface of steel castings. The grain size of as quenched structure is extremely uneven, showing the characteristics of double grain size.

4. Chemical composition inspection

Take samples from the impact sample, and use 5110VDV plasma emission spectrometer and DK606 infrared carbon sulfur analyzer to test the chemical composition. See the table for the results. It can be seen from the table that the chemical composition of the impact sample meets the requirements of ZG30CrNiMo in JB /t 5000.6-2007 general technical conditions for heavy machinery: steel castings.

5. Hardness test

The FM-310 microhardness tester was used to test the hardness of the cleavage morphology area and dimple morphology area of the impact specimen fracture of steel castings. The test force was 0.98 n, and the test force was maintained for 10 s. five test points were selected for each area. The average hardness of the cleavage morphology area was 334 hv0.1, and the average hardness of the dimple morphology area was 328 hv0.1. There was no significant difference in the hardness of the two areas.