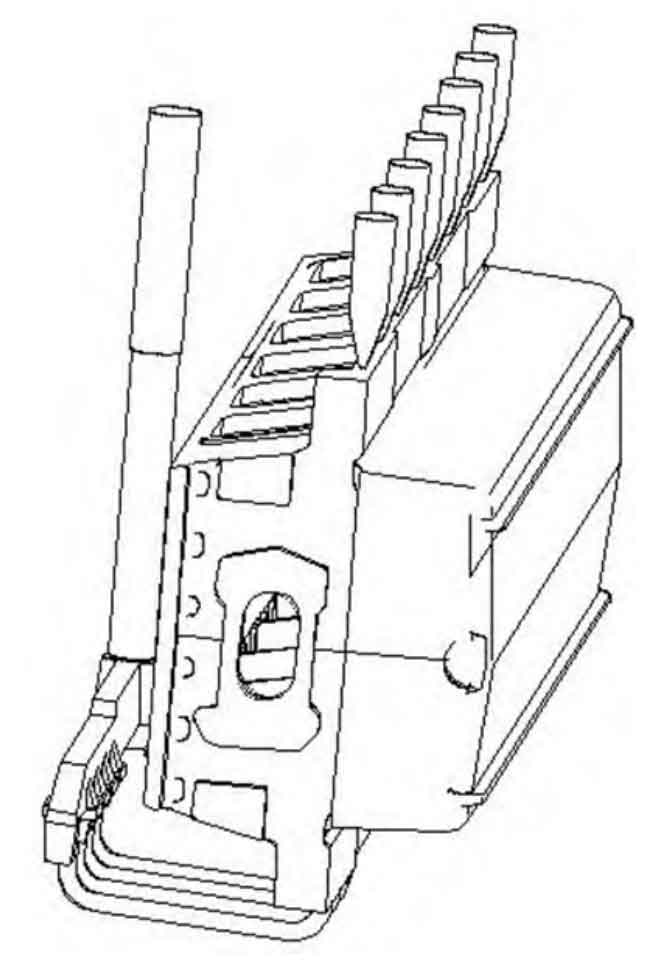

Resin sand is used for molding and core making. The compressive strength of resin sand is 5~7 kPa. Zircon powder alcohol based coating is used. The open pouring system is used. The cross-section ratio of each element is Σ f straight: ∑ f Cross: ∑ f inner =1:2:1.8, and the size is 12 mm × The specific casting process of 80 mm duckbill riser is shown in Figure 1. The pouring temperature is (1380 ± 10) ℃, and the pouring speed is 1.4 m / s. In order to prevent the casting defects of the large plane on the bottom of the oil pan, the horizontal vertical pouring process is adopted. Theoretically, this kind of horizontal and vertical casting process can solve the casting defects of the large plane at the bottom of the casting.

In order to prevent the turbulent flow of molten iron and achieve a stable pouring state, the bottom injection and open pouring system are adopted. Theoretically, this gray iron casting process is no problem, but in the actual production process, the middle core is difficult to locate, and the oil containing part of the casting is not allowed to use the core support, and the middle core can only be fixed on the upper box. In this way, the overturning operation after closing the box is very difficult, and there are potential safety hazards in the process of core overturning. At the same time, It is easy to cause sand inclusion and sanding defects in the process of turnover, which are not easy to be found and not convenient to clean.

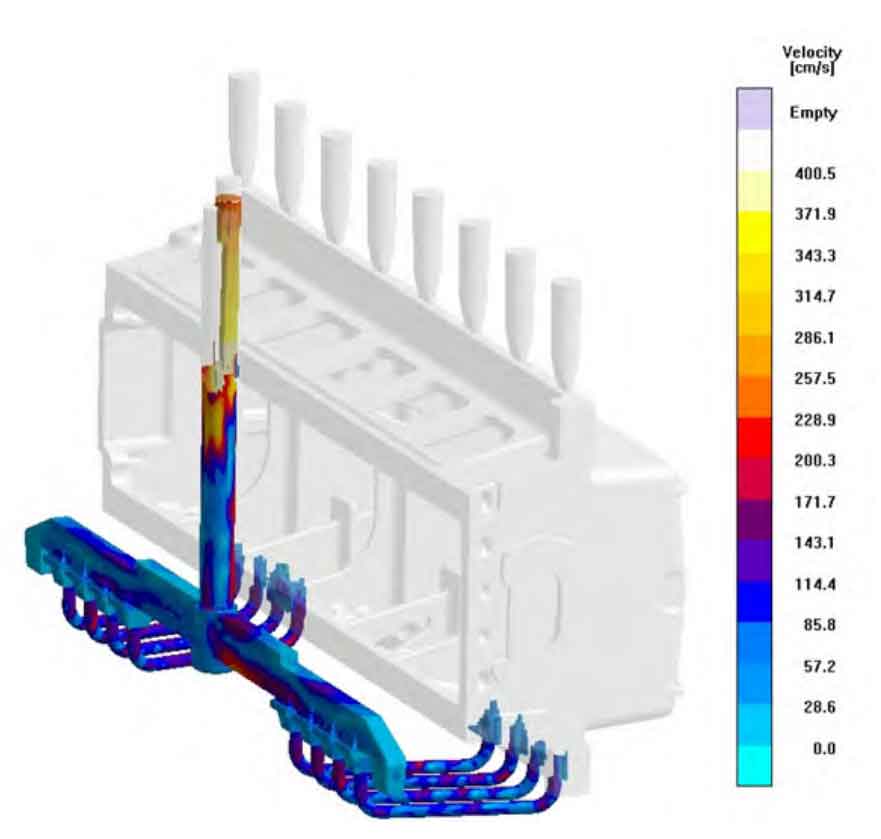

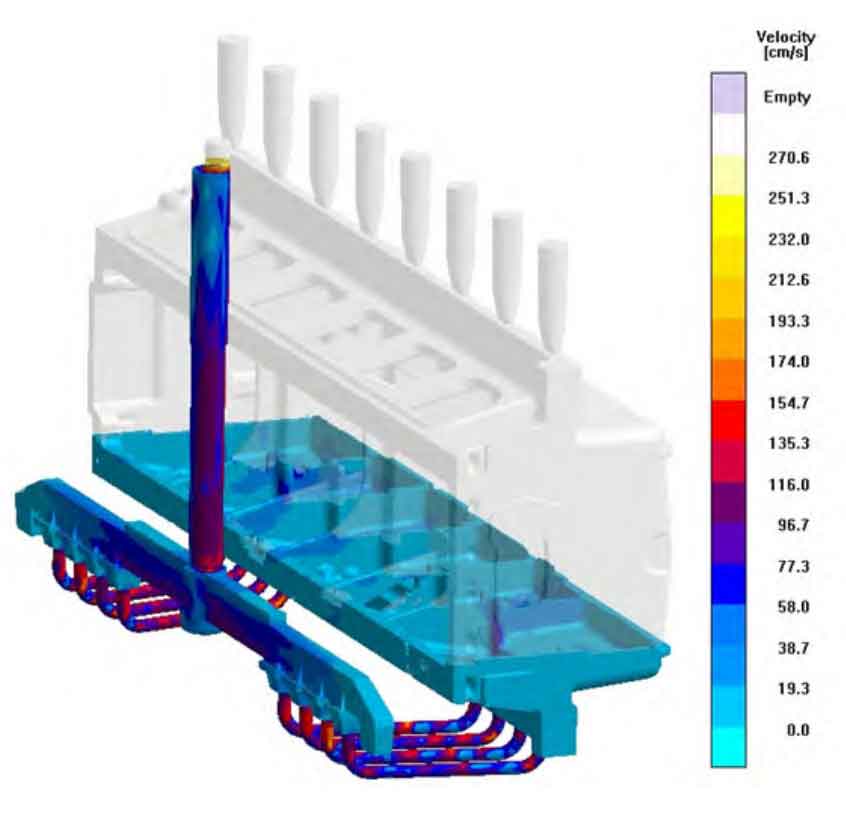

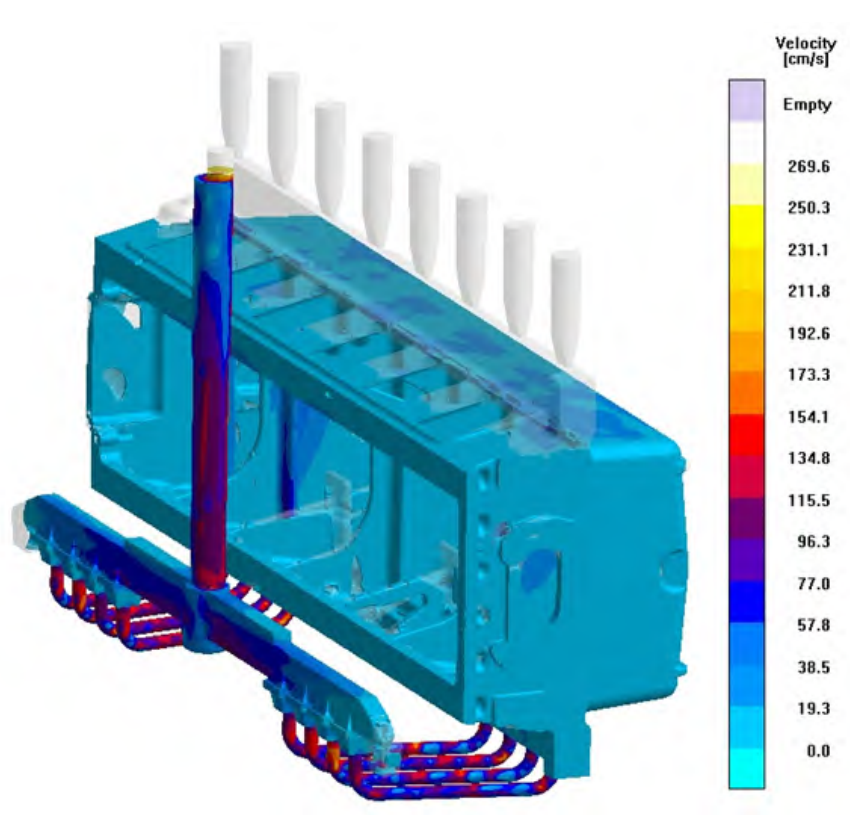

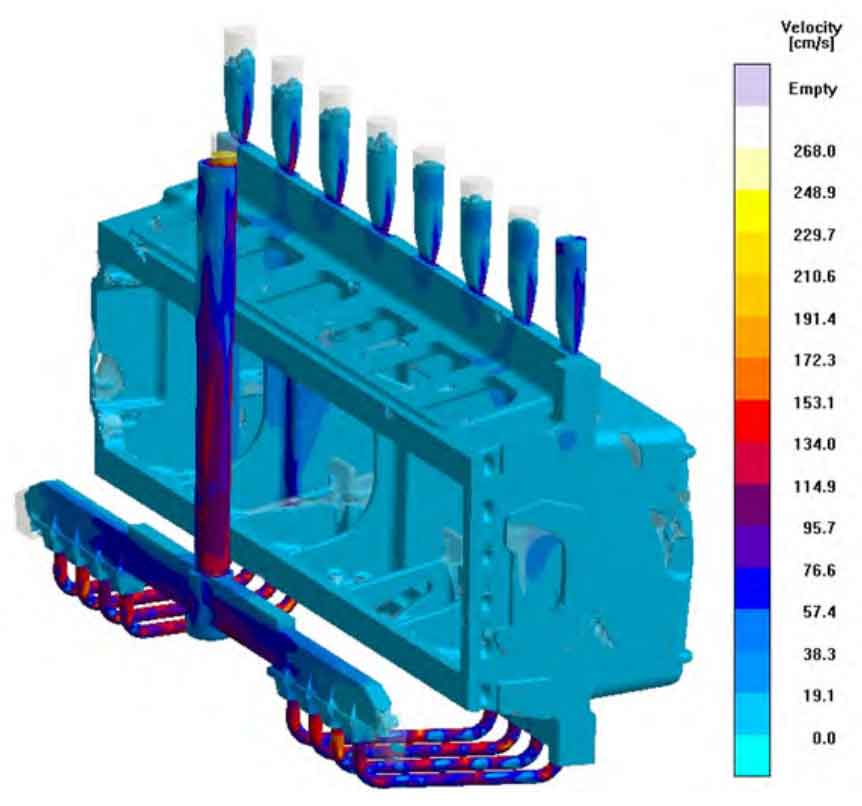

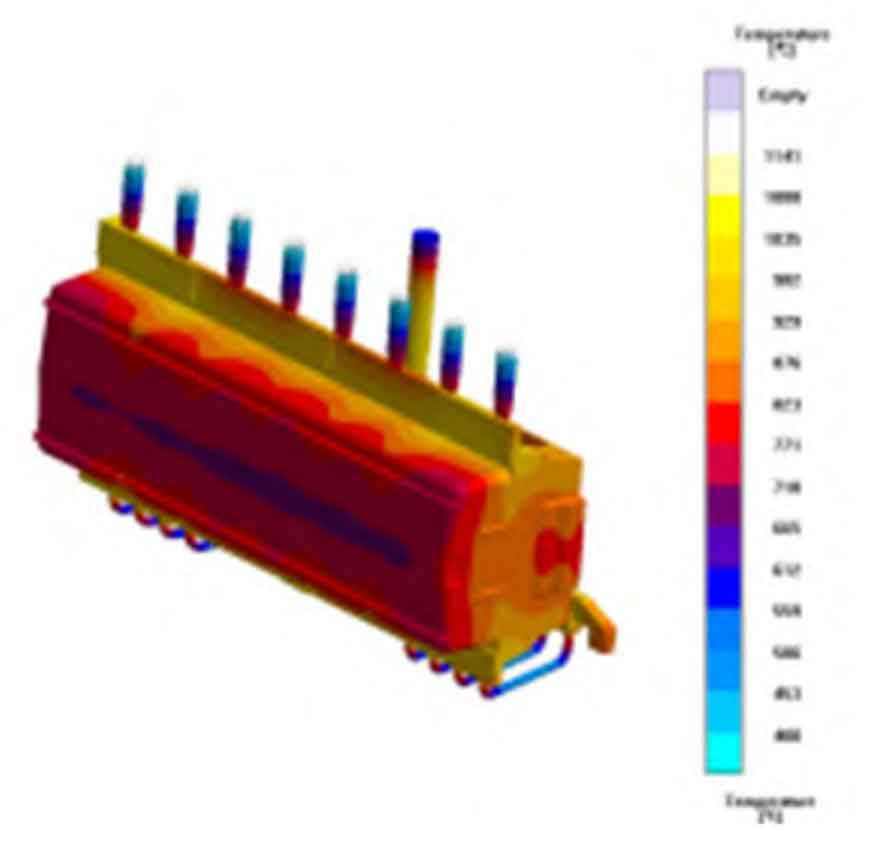

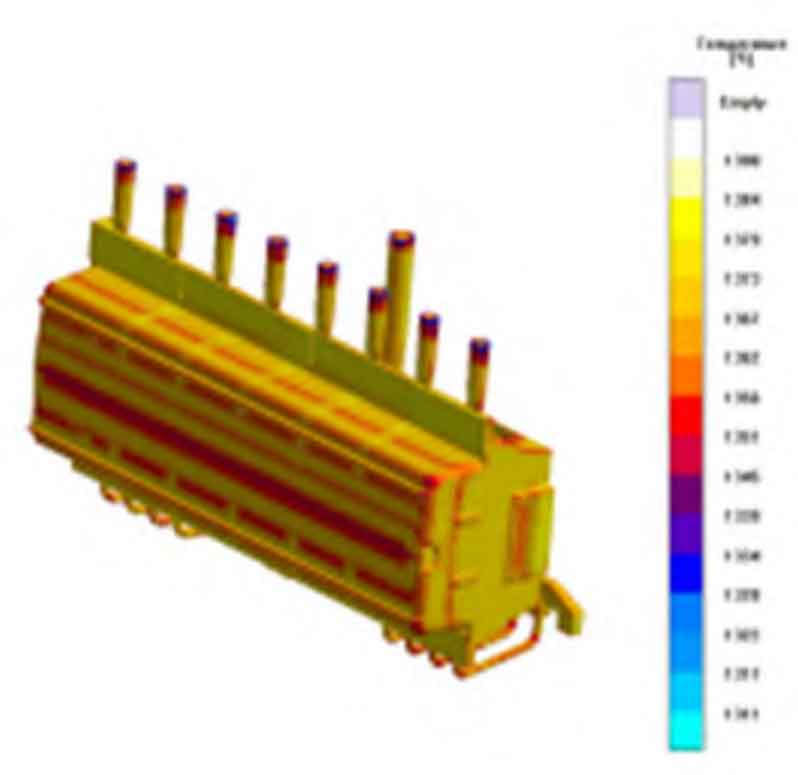

Figure 2 shows the simulation results of the mold filling process of the original process of gray iron castings. From the perspective of the mold filling process, the side pouring process has low temperature field in the rib area, uneven temperature distribution, and is prone to insufficient pouring and cold shut defects during the pouring process. Figure 3 shows the simulation results of the solidification process of the original process of gray iron castings. The temperature field at the top of the oil pan and other parts changes greatly and is very uneven, resulting in a greater probability of crack defects. Therefore, based on the actual production and simulation results, the process needs to be further optimized.