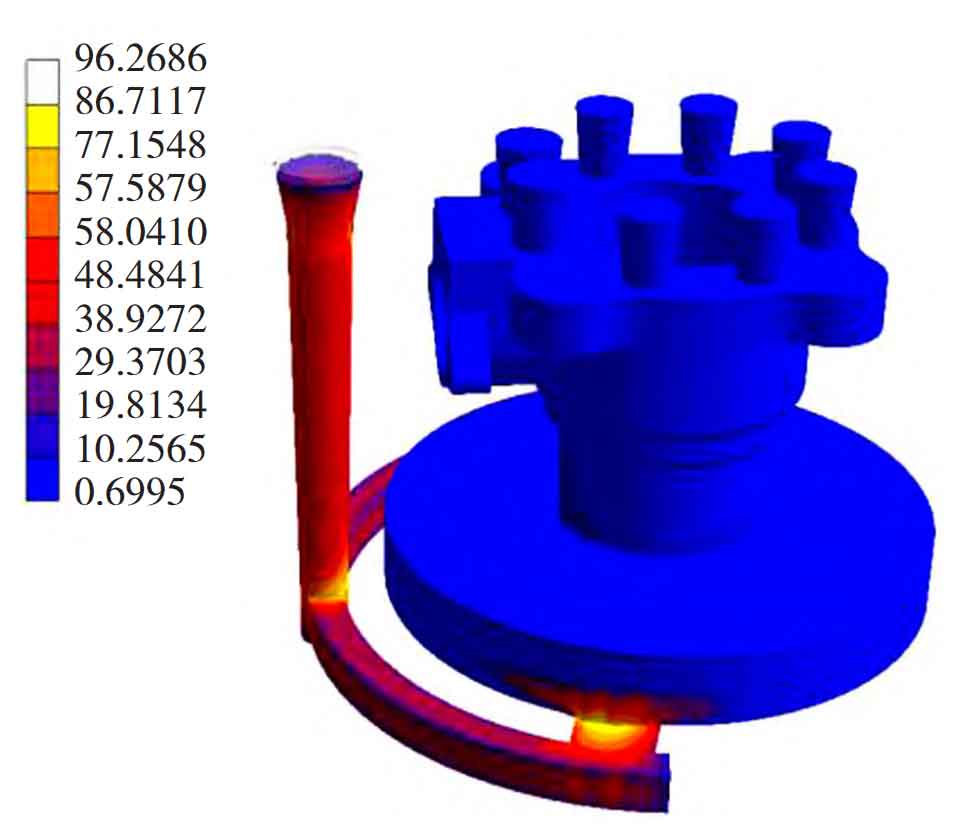

The casting process design of the flange ball valve was simulated by AnyCasting. The solidification sequence of the flange ball valve casting was obtained through simulation as shown in Figure 1. The solidification sequence of the flange ball valve casting was analyzed as follows: top, runner → middle of the casting → bottom disc center. The top sand core solidifies first because of its fast heat transfer rate in contact with the outside world; There is little liquid metal in the runner and the runner is fully contacted with the sand core, so the runner solidifies first; The bottom of the flanged ball valve casting contains a large amount of metal liquid, which causes the heat transfer rate to gradually decrease and requires a long time of solidification.

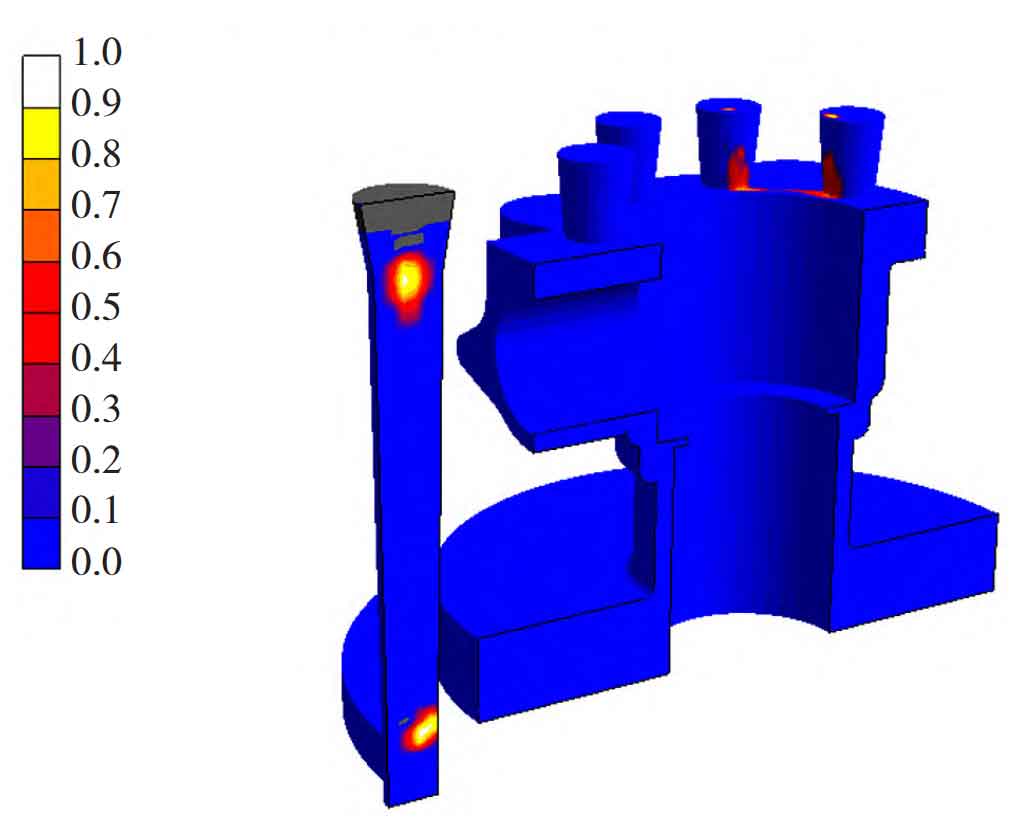

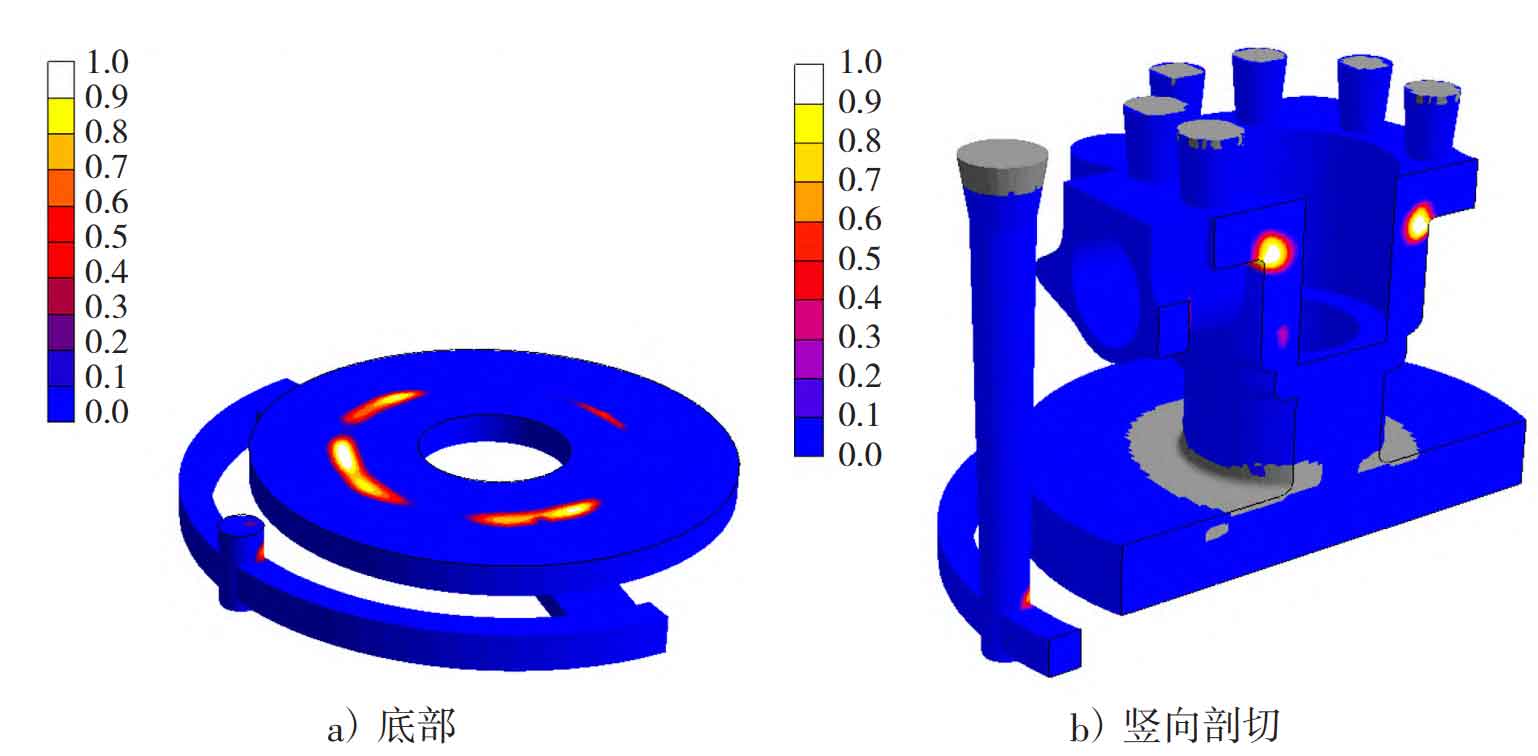

According to the solidification sequence of the flange ball valve casting, it can be predicted that shrinkage cavity, porosity and other defects occur at the final solidification position of the flange ball valve casting due to no metal liquid feeding, as shown in Figure 2a) Probability defect parameter diagram, cutting the bottom of the flange ball valve casting, and internal defects occur; At the same time, there are defects in the middle inner hole due to vertical cutting, as shown in Fig. 2b).

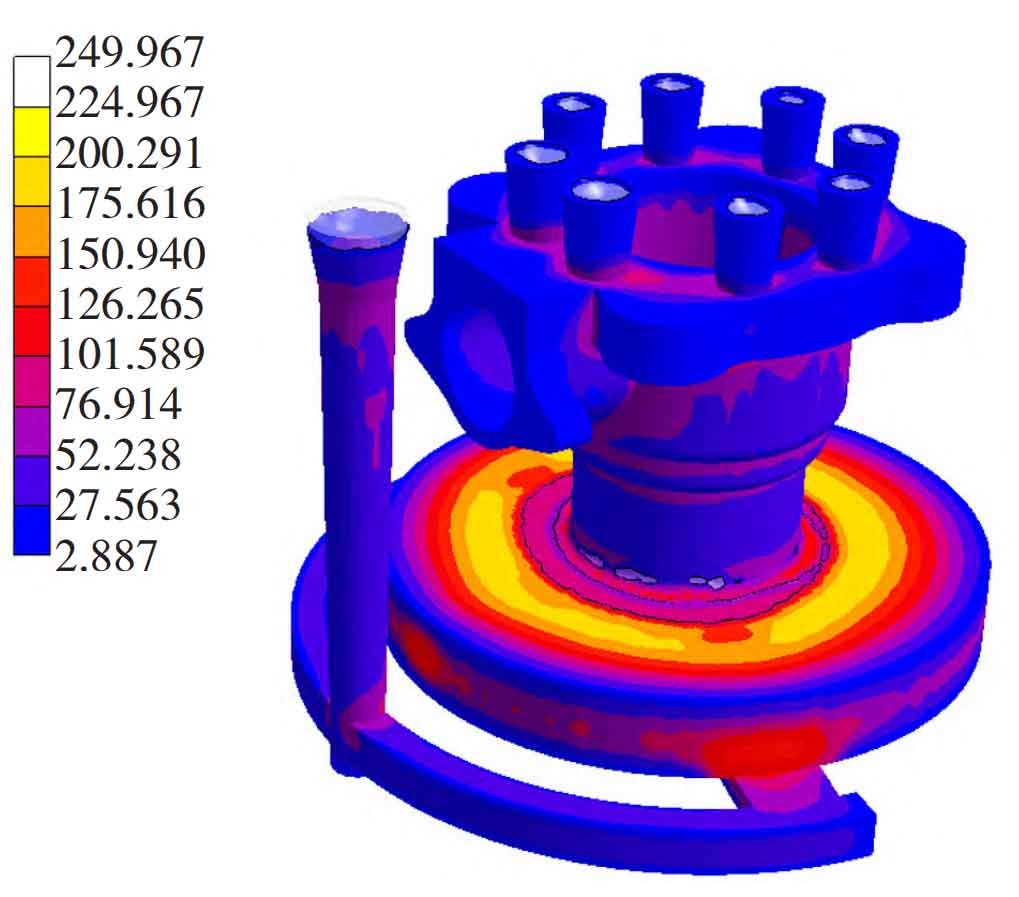

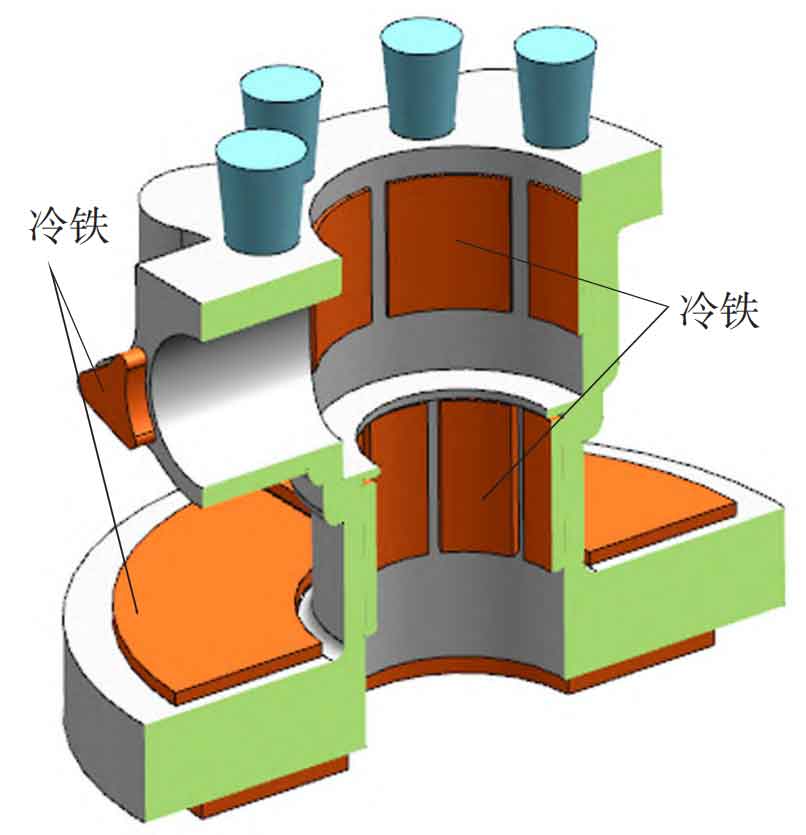

After comprehensive analysis, it is decided to improve the defects by adding cold iron, which essentially changes the solidification sequence of the flange ball valve casting, so that the flange ball valve casting can be fully fed. According to Fig. 1 and Fig. 2 Casting Solidification Sequence Diagram and Probability Defect Parameter Diagram, it is analyzed that cold iron blocks are added on the surface of the central inner hole of the flange ball valve casting and the surface of the bottom disc. The size, shape and location of the cold iron designed are shown in Fig. 3. The solidification sequence of the flange ball valve casting after adding cold iron is shown in Fig. 4 through numerical simulation of the flange ball valve casting after adding cold iron. It can be found that the solidification sequence of the flange ball valve casting has changed. The whole flange ball valve casting solidifies first, and the runner solidifies later. By observing the probability defect parameter figure 5 after adding cold iron, it is found that there is no defect at the bottom of the flange ball valve casting, and there is no defect in the whole flange ball valve casting. The defects are mainly concentrated at the riser position and the runner position, and the defects such as shrinkage porosity caused by feeding move to the riser.

The actual pouring was carried out according to the method of adding cold iron as shown in Figure 3. The actual water valve casting was obtained after processing as shown in Figure 6. The actual casting was inspected by X-ray flaw detection. Through analysis, it was found that there was basically no defect in the flange ball valve casting, and there was a small amount of shrinkage cavity at the top riser of the flange ball valve casting.