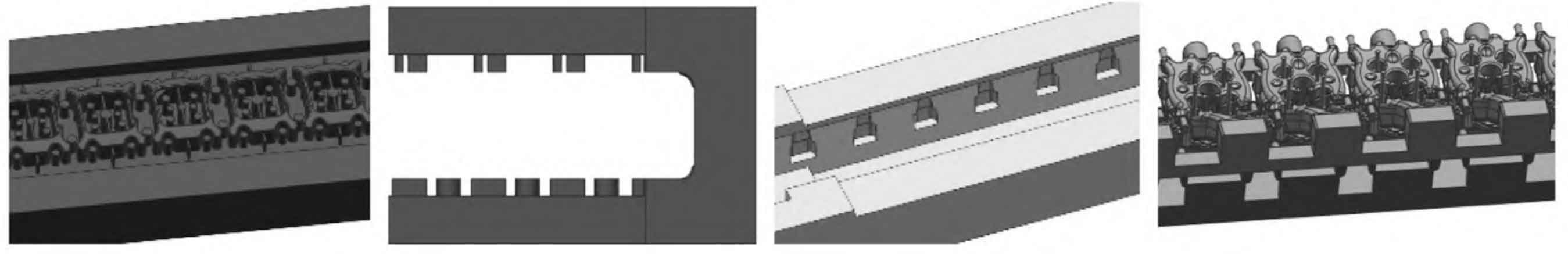

The cooling channel and inlet/outlet of the cylinder head are of special-shaped curved structure, with large wall thickness variation and numerous corners and distortion areas. The air passage is not connected with the upper and lower water channels, and the thinnest part is 3 mm. The relationship between the size and position of the sand core is strictly required. The traditional method needs to separate the upper/lower water channel and the inlet/exhaust channel inside the cylinder head (Fig. 1), and design an independent mold. Mold processing is difficult and time-consuming, which is not conducive to process improvement. It is difficult to form and position between sand cores, the production cost of castings is high, and the development cycle is long.

Research and use 3D printing technology to directly produce sand mold and sand core. The molding process is omitted, the product production cycle is shortened, and the sand mold of any complex shape is directly made, which is not limited by the mold processing technology, and the sand mold accuracy is guaranteed. The cylinder head outer skin sand mold is divided into three layers: upper, middle and lower. The whole 3D printing is applied layer by layer. The upper/lower channel and inlet/outlet channel sand core ends are extended and integrated into two sides of core heads. The integrated core is directly prepared by adding integral sand blocks at the bottom end face of the inlet/outlet channel sand core. Improve the dimensional accuracy and strength of the sand core of the integral cylinder head to avoid breaking during molding and pouring. The mold and sand core design scheme is shown in Figure 2.

| Project | Average gas generation/(mL · g-1) | Tensile strength/MPa |

| Laser sintering test block | 11.3 | 9.8 |

| Inkjet printing test block | 3.2 | 2.1 |

The inner core is the key to the forming of cylinder head castings. Due to the complex curved surface structure, there are many small and weak areas. During the anti-gravity casting process, the parts are easily broken due to the scouring and buoyancy of molten aluminum. The heated gas in the sand core is wrapped by high temperature aluminum liquid, which is difficult to be discharged in time, resulting in choking defect. Therefore, the strength and gas generation of the sand core are very important. In the experiment, three groups of laser-sintered 8-character samples and ink-jet printed 8-character samples were tested for tensile strength and gas generation respectively to obtain the average value of performance (see table). And press two 8-shaped samples into the bottom of the ladle containing 710 ℃ aluminum liquid, and compare the difference of gas generation between the two samples.

According to the comparison of the actual test data in the table, the strength of laser sintered sand core is 52% higher than that of inkjet printing, and the gas generation is 15.3% higher. In the actual aluminum liquid immersion, both sand cores will form large bubbles and float to the liquid level. To sum up, the complex sand core of cylinder head is prepared by laser sintering (as shown in Figure 3). In view of the gas generation problem of the sand core, it needs to be further optimized from the core structure design and enhanced exhaust.