1. Optimization design scheme of ductile cast iron parts for high-pressure cylinder end cover

The production and numerical simulation analysis of the original process design show that when the molten iron solidifies, the narrow feeding channel of the riser leads to shrinkage cavity and porosity defects in the ductile iron castings. In view of the deficiencies of the original process plan, combined with the technical requirements that the product surface should be free of obvious shrinkage porosity, shrinkage cavity, sand hole and other defects, the optimization process idea is proposed:

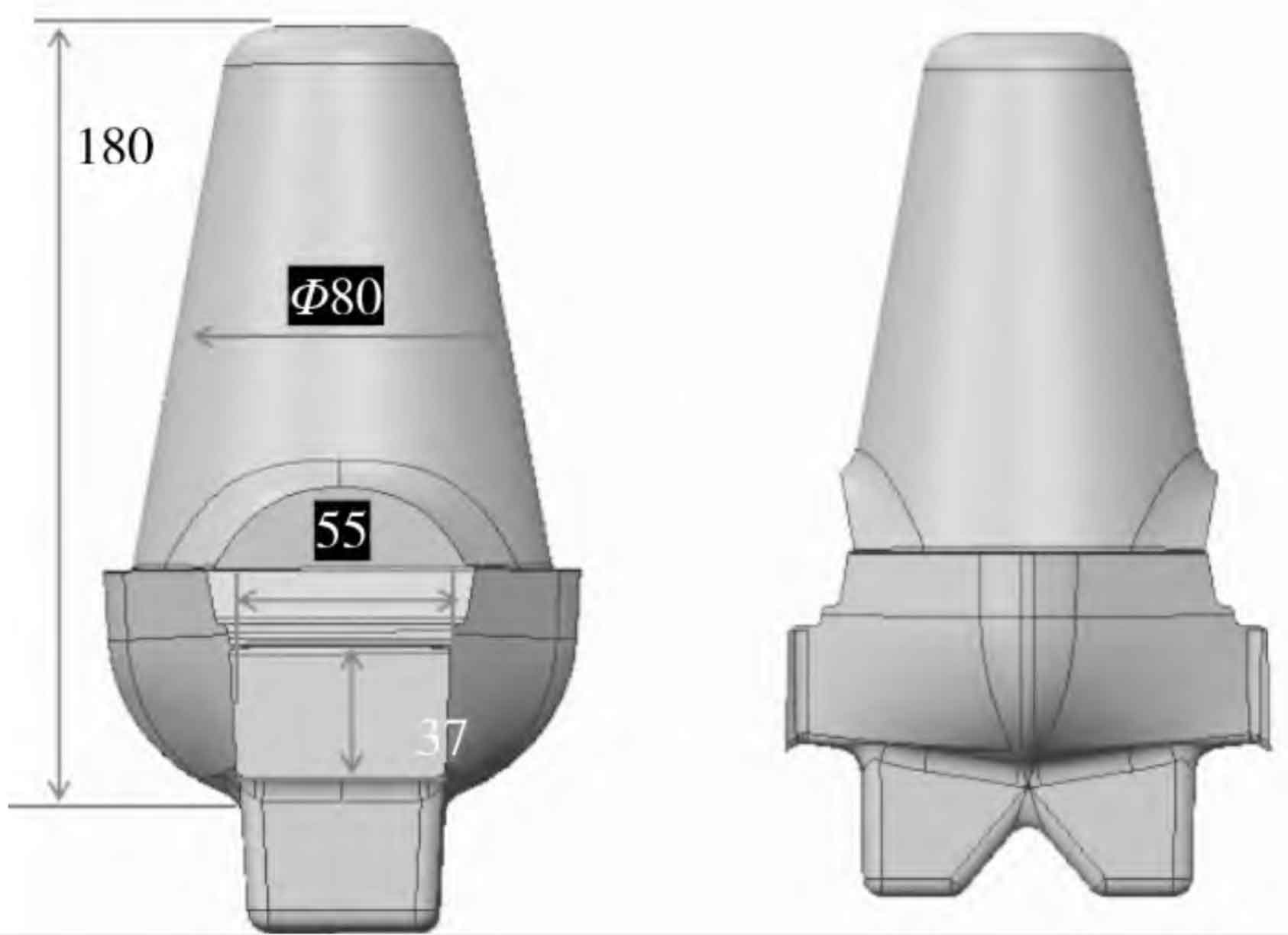

① The riser neck is widened by 10 mm and thickened by 10 mm to increase the feeding fluidity of the riser neck. See Figure 1 for details;

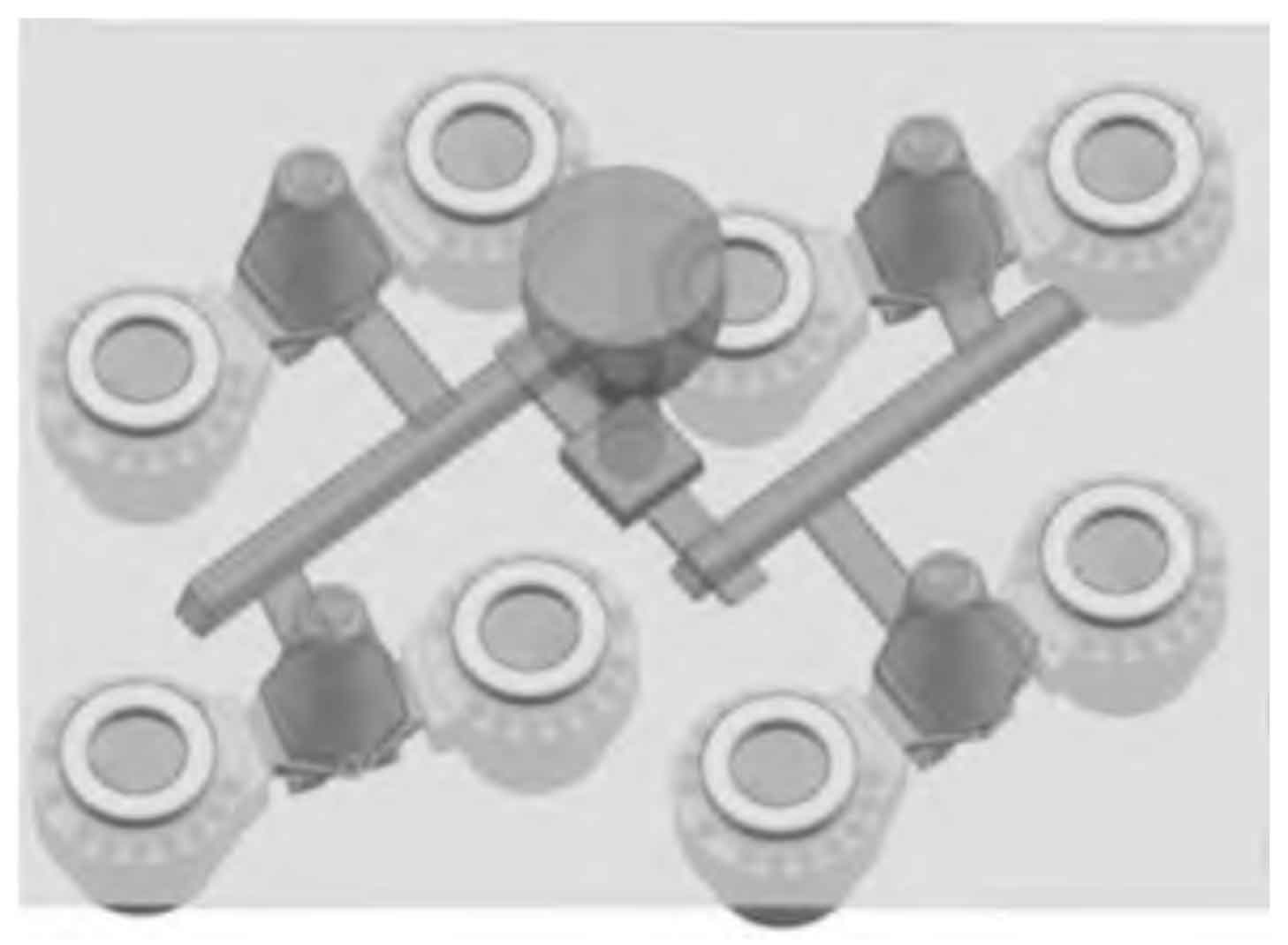

② The number of ductile iron castings for each riser feeding is changed from 3 to 2;

③ The flow distance of molten iron from the sprue to the ductile iron castings in the transverse sprue is shortened; The optimized process plan is shown in Figure 2.

2. Simulation and analysis of the optimized design scheme of the ductile cast iron part of the high-pressure cylinder end cover

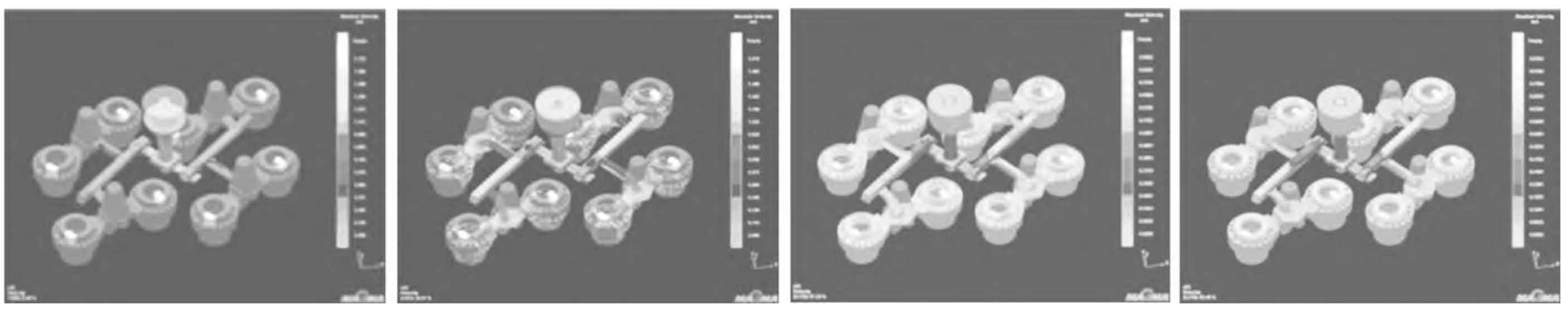

In order to further explore and confirm the elimination of defects such as sand holes, shrinkage holes and shrinkage porosity in the ductile cast iron parts of the high pressure cylinder end cover. MAGMA software is used to simulate the mold filling in each time period of the optimized process plan. It can be seen from Figure 3 that the optimized process has basically achieved the design goal. The entire inner gate is always in a full state during the filling process, and the temperature at the riser is always the highest from the perspective of temperature field. During the whole pouring process, the metal level is relatively stable and there is less turbulence.

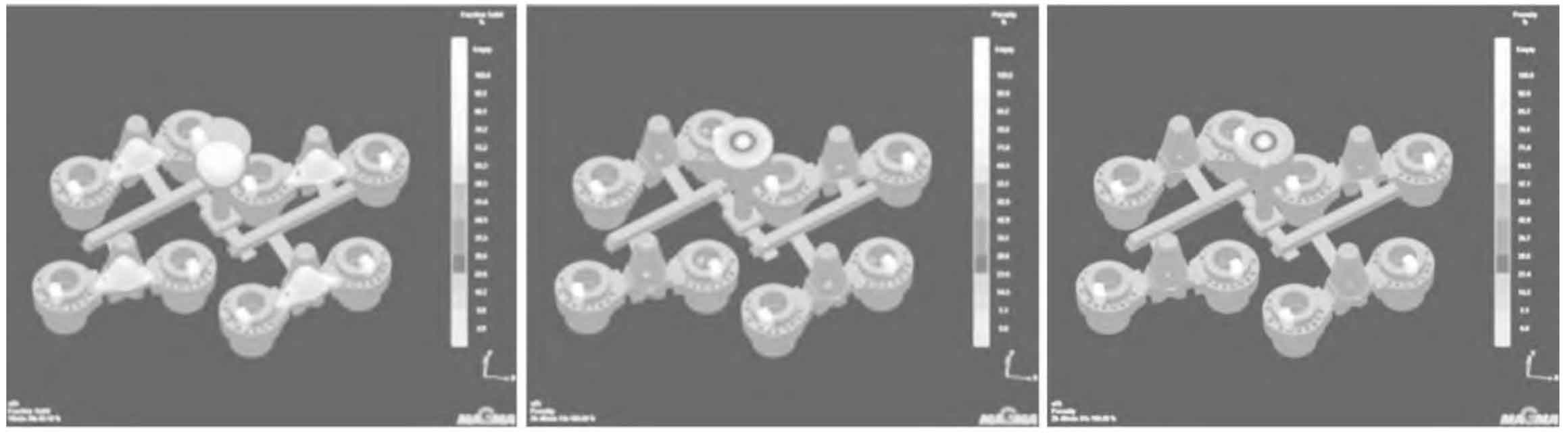

Figure 4 shows the simulation of feeding system by MAGMA software. It can be seen from Fig. 4a that during the solidification process, the part of ductile cast iron near the riser solidified earlier and the remaining liquid phase feeding channel was broken, and the ductile cast iron could not be fed. From the shrinkage simulation in Fig. 4b, it can be seen that there is no shrinkage cavity in the remaining liquid phase of ductile iron castings, only regional shrinkage porosity. The shrinkage porosity is analyzed. When “X-ray=5” indicates that the shrinkage porosity is simulated and filtered by 5%, the shrinkage porosity less than 5% can be completed by self-feeding.

3. Trial production and quality analysis of ductile iron castings

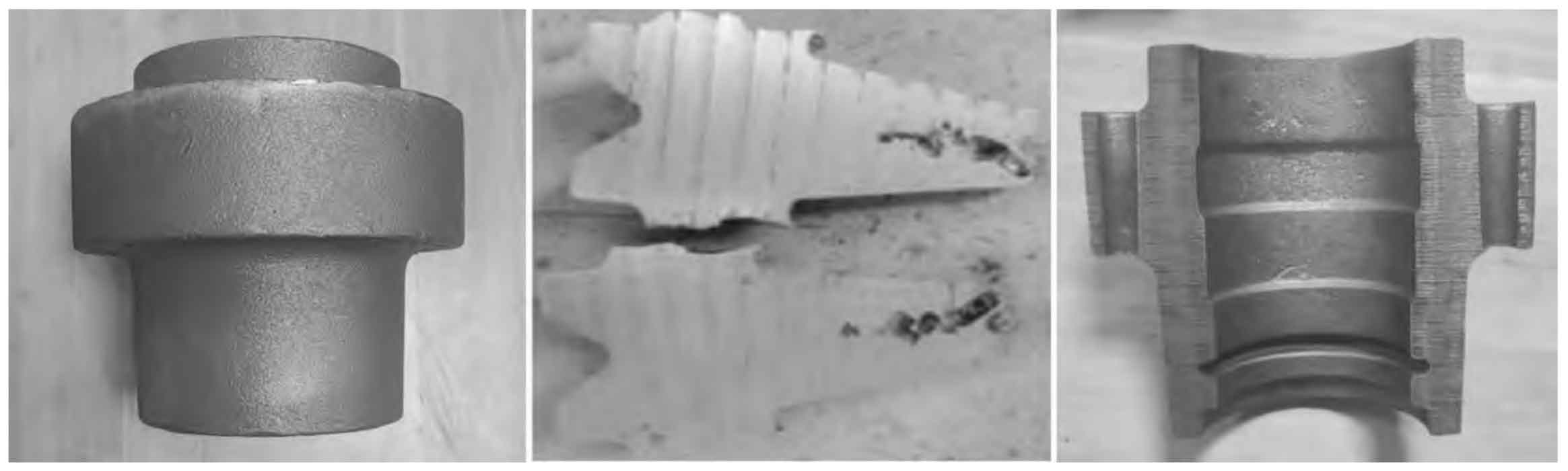

See Fig. 5a for the ductile iron parts of the high-pressure cylinder end cover trial-produced by the optimized design scheme. No obvious defects such as shrinkage cavity, shrinkage porosity and sand hole were found on the surface of ductile cast iron. In Fig. 5b, after removing the riser of ductile cast iron, it is found that the riser neck is obvious, which indicates that the riser has played a significant role in feeding, so that the shrinkage cavity, shrinkage porosity and other defects disappear, and dense ductile cast iron is obtained.

(b) Anatomical drawing of optimized riser

(c) Anatomical drawing of optimized casting